engineering drawing sheet metal part This article will provide a series of key sheet metal design and fabrication guidelines to help engineers and designers understand how to maximize the use of the characteristics of metal sheets, ensuring the feasibility . $450.00

0 · solidworks sheet metal drawings

1 · simple sheet metal drawings

2 · sheet metal layout drawings

3 · sheet metal drawings with gd&t

4 · sheet metal command in solidworks

5 · sheet metal basic drawing

6 · sheet metal 3d sketch solidworks

7 · metal sheet riveted together drawing

$41.89

solidworks sheet metal drawings

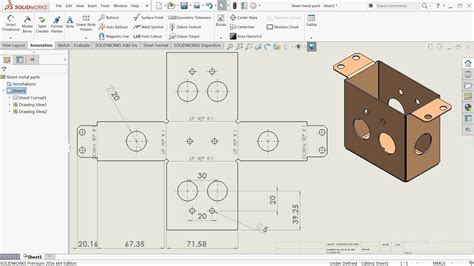

This article will provide a series of key sheet metal design and fabrication guidelines to help engineers and designers understand how to maximize the use of the characteristics of metal sheets, ensuring the feasibility . Sheet metal parts are typically created from material less than .250 inches thick, and are formed by folding the material at specific locations with a controlled bend radius. See

box of 9mm full metal jacket price

Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this . An engineering drawing is a subcategory of technical drawings. The purpose is to convey all the information necessary for manufacturing a product or a part. Engineering .Sheet metal DFM - design guidelines for formed and punched parts. A first principles look at sheet metal design for manufacturability for experienced engineers. Sheet metal design skills are a crucial tool in any engineer’s .

5 Ways to Optimize Drawings for Precision Sheet Metal Fabrication Services. Follow these best practices next time you create a sheet metal fabrication drawing to help your shop turn the project around quickly: 1. .This chapter explains how to create sheet metal drawings. Gauges for sheet metal are presented along with bend radii, flanges, tabs, reliefs, and flat patterns.

Accuracy in sheet metal drawings is paramount as it directly impacts the quality, fit, and functionality of fabricated components. Precise dimensions, tolerances, and material specifications ensure that parts align . Our design guide to properly drafting sheet metal drawings and specifications for your supplier to get more accurate quotes and faster design for manufacturing (DFM) feedback. Get ready to explore the cutting-edge techniques and creative problem-solving that make sheet metal fabrication a critical part of product development. Shane; August 5th, 2023; Sheet Metal Forming; . Sheet Metal .

Sheet Metal Gauge Callouts in Drawings 2. Thread starter wblanchard; Start date Mar 11, 2011; Status . Sheet metal fabricators know their sheet metal guages. They can read your numbers, and select the correct sheet from stock. . They need to know whether to accept or reject the part they are inspecting. Tell your shop you need .091±.015 . Drawings will need to be converted to a flat pattern for fabrication, however, and 2D drawings are far more useable in sheet metal manufacturing. Where 3D drawings are used, they should be made with a sheet metal .Open the sheet metal part for which you want to add a drawing. Click Make Drawing from Part/Assembly (Standard toolbar), and click OK to open the drawing sheet.. Select a format or click OK to use the default format.. From the View Palette, drag the Flat pattern to the drawing sheet. You can adjust the size of the drawing view under Scale by selecting Use custom scale, .Just make sure its in the engineering drawing format for manufacturing (i.e. tolerances, dimension, views, enough information for person to interpret and make.) see GD&T for more details Shops that have the compatibility to work on sheet metal will have the tools. Most shops work with high volume. . Model your part using SOLIDWORKS Sheet .

My biggest problem with other people's sheet metal drawings is that they use drawing templates designed for machined parts, showing standard machining tolerances. Sheet metal shops can bend to around +/-.015" accuracy. In response, sheet metal fabricators are going digital with adoption of advanced CAD-CAM technology for sheet metal detail drawings and cloud-based designing solutions. Stepping into the digital and standardized environment offered by CAD platforms is providing the way for sheet metal fabricators to stay responsive to market needs. one of the complicated sheetmetal part in solidworks, you will learn how to read engineering drawings and also you will learn how to make a . Learn about the GrabCAD Platform. Get to know GrabCAD as an open software platform for Additive Manufacturing . Sheet Metal Part for Practice. Folder. August 19th, 2023 View comments (0) Comments (0 . One of our customers has requested numbering to be stamped or engraved into some formed sheetmetal pieces we offer. These numbers require specific location, depth and size. This is the first time I have been asked to include this information on a drawing and am wondering if you all could point me in the right direction as to how to correctly call out the font, .

DESIGN/ENGINEERING . How to Dimension Rolled Sheet Metal Cuts in SOLIDWORKS Drawings. When cuts are made into the flat pattern of a rolled sheet metal cylinder (or semi-cylinder . By using these commands, we introduce a flat pattern before the Flat-Pattern folder that exists on every Sheet Metal part. This allows us cut geometry and re-roll . SolidWorks 2022 Step-By-Step Guide (Colored): Part, Assembly, Drawings, Sheet Metal, & Surfacing Pages: 438 Contents: Chapter 1, “Getting Started with SolidWorks 2022 Chapter 2, “Basic Sketching tools” Chapter 3, “Advance Sketching & Editing Tools” Chapter 4, “Applying Dimensions & Geometric Relations” Chapter 5, “Solid Modeling Tools” Chapter 6, . Table of Contents. 1 5 Ways to Optimize Drawings for Precision Sheet Metal Fabrication Services. 1.0.1 1. List part numbers, not just the part name; 1.0.2 2. Use the exact hardware name when possible; 1.0.3 3. Provide details for revision control

This information is critical when documenting the mirrored part on a production drawing. Introduced in SOLIDWORKS 2015, when creating mirrored versions of sheet metal parts it is now possible to transfer the sheet metal and flat pattern information from the original part to the mirrored part, saving you a huge amount of time during the drafting .This chapter explains how to create sheet metal drawings. Gauges for sheet metal are presented along with bend radii, flanges, tabs, reliefs, and flat patterns. Sheet Metal Drawings. Figure 13-1 shows a 3D solid model of a sheet metal part and a dimensioned orthographic drawing of that part. The orthographic drawing was created from the 3D model.This variety can sometimes cause engineering drawing reviews to be difficult without a structured review process. It's easy to overlook things if you aren’t careful. Since much of what is included in a great part drawing for manufacturing should be similar across drawings, we’ve developed a free checklist for reviewing your part drawings.i worked at a large company with a world-class sheet metal manufacturing plant attached. we were required to provide a flat pattern view with each sheet metal drawing, but dimensions were not required. the purpose here was to "prove" .

In a part generated with the Sheet Metal tools, Bend Lines are stored in the Flat Pattern feature. Show/hide and suppress/unsuppress to control how and when these sketches are displayed. By default, they are always in . See more at: http://www.goengineer.com or http://www.goengineer.com/products/solidworks/ or http://www.goengineer.com/govideochannel/Learn about a few featur.When you create a drawing of your sheet metal part, a flat pattern is automatically created. Drawings of sheet metal parts can also contain views of the bent sheet metal part. You can create *.dxf files of sheet metal flat patterns without creating a drawing. Contents.Study with Quizlet and memorize flashcards containing terms like The term sheet metal refers to metal that has been rolled into a sheet., The standard ASME Y14.31-2008, Undimensioned Drawings provides the requirements for undimensioned drawings that graphically define objects with true geometry views and predominantly without dimensions. This standard also provides .

There you have the option to “generate a flat pattern” which you can easily add to the main drawing. If you are using the standard part environment, the same option is not available. Still, many CAD programs can convert a standard part into sheet metal if the part properties correspond to sheet metal (e.g. uniform thickness, inside radius . There are three methods of working sheet metal in, presses :, , (1) Shearing : It is a sheet-metal cutting operation along a straight line between two cutting edges., Shearing is used to cut large sheets into smaller sections for subsequent pressworking operations., , (i) Deep Drawing : It is characterized by the production of a parallel-wall .

First, check out ordinate dimensioning, it can really clean up sheet metal drawings where you need to show hole locations but don't have space for dozens of stacked dimension lines. With ordinate dimensions, I would be surprised if you need more than two front views for a single part. Sheet metal parts can generally be divided into three categories: flat parts (i.e., general flat stamping parts), bending parts (i.e., parts formed by sheet bending or bending processing), and forming parts (i.e., parts made by drawing and other forming methods, either regular or free-form surface parts). Sheet metal parts differ significantly from parts produced by .

Explore essential quality metrics for sheet metal fabrication drawings. Ensure precision and efficiency with expert insights from HitechDigital. . This specification is achieved by symbols and notations that are part of the standardized language used in engineering drawings to communicate the level of finish required on each surface of a part . Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, dimensions, material, surface treatments, allowable tolerances, and other pertinent information.We follow Sheet metal design guidelines to ensure the quality and manufacturability of sheet metal enclosures. As a result, you can deliver the product at a low cost and faster timeline. It is difficult to follow all sheet metal design guidelines for complex sheet metal parts. Therefore exceptions can be there for complex sheet metal parts.

simple sheet metal drawings

sheet metal layout drawings

box junctions highway code

sheet metal drawings with gd&t

$8,425.00

engineering drawing sheet metal part|sheet metal drawings with gd&t