cnc diy molding machine We'll provide you with a step-by-step guide on assembling your CNC machine kit. Starting with the frame, we'll guide you through installing the rails, mounting the motors and drivers, . you may be surprised that the main chassis rails are 2mm (measured mine with vernier !) other areas are thicker, like trailing arm mounts, out rigger triangulation, panhard rod brackets etc. if you start letting in large areas of 3mm repairs into 2mm steel, because more is bettererer, it will tend to divert stresses onto abnormal parts of the .

0 · make your own cnc machine

1 · how to build a cnc machine

2 · diy stepper motor for cnc

3 · diy cnc router

4 · diy cnc machine kit

5 · cnc moulding

6 · cnc machine for mold making

7 · cnc injection molding machine

Couplings slip inside the ends of two round ducts to be joined together and then sheet metal screws are fastened to hold it in place. Couplings could be required at a certain size such as connections 18” and larger.

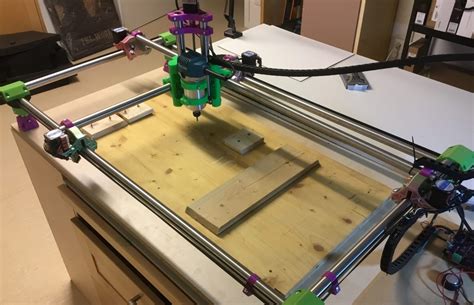

Fortunately, with the right skills and resources, it is possible to build your own DIY small CNC machine. In this blog post, we will guide you through the step-by-step process of building your .We'll provide you with a step-by-step guide on assembling your CNC machine kit. Starting with the frame, we'll guide you through installing the rails, mounting the motors and drivers, .Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, .

Building a CNC machine requires careful planning and design. In this section, we will discuss the essential components you'll need, such as stepper motors, controller boards, power supplies, and more. We'll guide you through choosing the appropriate materials and discuss different design options to suit your specific needs. 3.Fortunately, with the right skills and resources, it is possible to build your own DIY small CNC machine. In this blog post, we will guide you through the step-by-step process of building your own CNC machine, from sourcing materials to programming the machine. The best DIY CNC routers give you access to repeatable precision and reliability for your projects – without paying thousands of dollars for professional machines. My top choice for beginners is the Sainsmart Genmitsu 3018 PRO .We'll provide you with a step-by-step guide on assembling your CNC machine kit. Starting with the frame, we'll guide you through installing the rails, mounting the motors and drivers, connecting the electronics, and calibrating the machine. Clear and detailed instructions, accompanied by visuals, will help you execute each step with confidence.

Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

make your own cnc machine

I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I include all of the necessary steps I went through in designing and building this CNC milling machine.In this Instructables, I’ll show you how I designed, fabricated, assembled, and got running this mini CNC milling machine. I love fabricating and I wanted to make a (relatively) low cost CNC mill to have at home during the pandemic. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know. Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __

Learn how two brothers made a desktop injection molding machine and use the takeaways from their process to build your own.

how to build a cnc machine

Building a CNC machine requires careful planning and design. In this section, we will discuss the essential components you'll need, such as stepper motors, controller boards, power supplies, and more. We'll guide you through choosing the appropriate materials and discuss different design options to suit your specific needs. 3.Fortunately, with the right skills and resources, it is possible to build your own DIY small CNC machine. In this blog post, we will guide you through the step-by-step process of building your own CNC machine, from sourcing materials to programming the machine.

The best DIY CNC routers give you access to repeatable precision and reliability for your projects – without paying thousands of dollars for professional machines. My top choice for beginners is the Sainsmart Genmitsu 3018 PRO .

We'll provide you with a step-by-step guide on assembling your CNC machine kit. Starting with the frame, we'll guide you through installing the rails, mounting the motors and drivers, connecting the electronics, and calibrating the machine. Clear and detailed instructions, accompanied by visuals, will help you execute each step with confidence.Building your own 3-Axis CNC router is both fun and educational. These plans document all the steps I followed to make my DIY CNC Router. This is the second DIY CNC Router I made, after learning a lot from building the first version. This is a very good router that can be built at a reasonable price using readily available materials. This

I know a lot of CNC dreamers do not have the knowledge or tools to build a full metal machine. I still think and hope this Instructable inspires you to make your own machine. I include all of the necessary steps I went through in designing and building this CNC milling machine.In this Instructables, I’ll show you how I designed, fabricated, assembled, and got running this mini CNC milling machine. I love fabricating and I wanted to make a (relatively) low cost CNC mill to have at home during the pandemic. A DIY CNC router may sound like a fun project, but it can be a challenge even for discerning makers. Here's what you need to know.

chairs with colored fabric & metal legs

Turn your woodworking shop into a machining, cutting, carving, and milling powerhouse with our shop-made, CNC machine. __Get the step-by-step plans for this Shop-Built CNC Router at WoodsmithPlans.com. __

certified roofing and sheet metal tickfaw la

diy stepper motor for cnc

Junction boxes come in various sizes, and the screw size depends on the specific box size. For smaller junction boxes, #6 (3.5mm) screws with a length of 0.75 to 1 inch (19 to 25mm) are commonly used.

cnc diy molding machine|cnc moulding