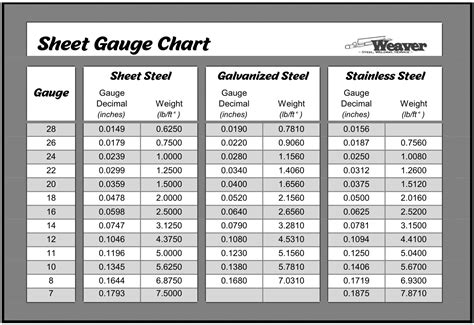

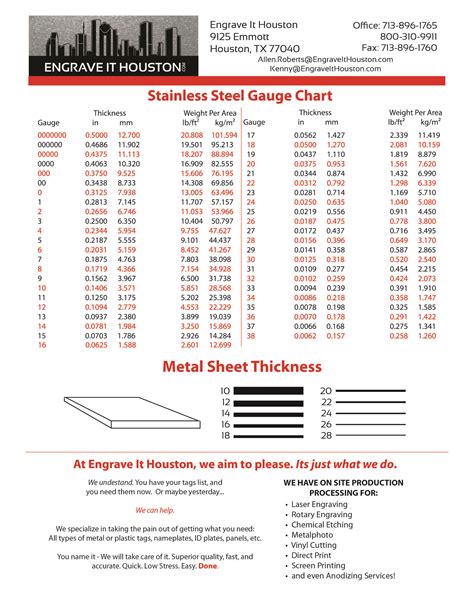

how to measure the thickness of sheet metal How to Measure Sheet Metal Thickness? There are two ways to measure sheet metal: using a measuring tape (which is less precise) and a . When you are using metallic thread, the correct needle to use is the DBx7ST. This needle is identical to the DBxK5 except the eye is elongated and rectangular in shape so that the metallic thread will

0 · steel gauge thickness chart mm

1 · stainless sheet gauge thickness chart

2 · sheet metal thickness chart wikipedia

3 · sheet metal specifications chart

4 · sheet metal sizing chart

5 · sheet metal gauge chart metric

6 · galvanized steel gauge thickness chart

7 · galvanized sheet metal thickness chart

Steel ammo cases are typically made through a process called deep drawing, which involves forming a flat sheet of steel into a cylindrical shape. This manufacturing method ensures strength, durability, and precision for these essential components of ammunition.

The chart below can be used to determine the equivalent sheet thickness, in inches or millimeters, for a gauge number from the selected gauge size standard. The weight per unit area of the sheet can also be seen in pounds per square foot and kilograms per square meter.

Pure metal / Used as an alloy element for aluminum, lead, zinc, and other . How to Measure Sheet Metal Thickness? There are two ways to measure sheet metal: using a measuring tape (which is less precise) and a . To find out the actual thickness of sheet metal, you can refer to a gauge conversion chart. This chart helps translate gauge numbers, such as 18 gauge, into familiar .

Sheet metal thickness is measured in gauges; the higher the number, the thinner the sheet metal. The most commonly-used sheet metal sizes range from 26 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool . Sheet metal gauge charts are invaluable tools in the metalworking industry. They provide essential information about the thickness of the sheet metal to help you choose the perfect measurement for your design. A sheet metal gauge chart is an essential reference tool in metal fabrication that correlates gauge numbers with precise material thicknesses for various metals. Understanding how to interpret these charts is crucial for . The gauge of a sheet of metal is a reference to how thick it is. The higher the numbered gauge a piece of metal is, the thicker the piece is in millimeters. If you want to find out what gauge your sheet metal is, measure its thickness using a regular tape measure.

To provide metalformers with a reliable and dependable process to instantly and accurately measure lubricant thickness, and to determine its distribution across the complete coil or sheet surface, Amepa GmbH (Amepa America Inc., Middleburg Heights, OH) has introduced an oil-film measurement (OFM) system. Sheet gauges start at .010” and go up to .170” (or 7 gauge) The thickness for plate sizes can be from .188” and up; . The most precise way to measure a metal’s thickness is to use a caliper. Calipers are hand tools . Solution 1: Measuring Sheet Metal Thickness With Tape. There are three simple steps required in this, and they include: Step 1. Use the millimeter hash marks on your tape to find the thickness of sheet metal. Remember that there are two different measurements on your tape, namely the cm and mm. Using the former will not provide the accurate .

A gauge is a traditional, non-linear measurement. The most commonly used sheet metal sizes range from 30 gauge (thinner) to 7 gauge (thicker). A sheet metal gauge tool is used to measure metal thickness, and show both the gauge number as well as the thickness of the metal in thousandths of an inch. One general rule across both though is that the higher the gauge, then the thinner the metal with the most commonly used sheet metal gauges ranging from the thinner end of the scale around 30 down (or up) to thicker sheets of around 7 gauge. Step 2: Measure Expanded Metal Thickness. Using a caliper, measure the thickness of the expanded metal sheet or panel. This will help you determine the gauge or wire diameter of the material. Expanded metal is defined by its mesh size, which refers to the distance between two adjacent strands. Measure the mesh size using a ruler or tape measure. You can also use a thimble to measure the thickness of sheet metal parts. This will help you find out how thick or thin the part is. You should take note of the distance between the tabs and the bend so that they don’t distort the sheet metal. If you don’t follow these rules, the part might become inaccurate.

In this video we demonstrate using an AR700 Laser Displacement Sensor for counting sheet metal, as well as any other pre-determined stacked thickness material. By pairing our sensor with our touch panel display, we use non-contact thickness measurement as an in-line counting system, handy for any number of production or assembly line environments.

Sheet metal gauge charts are invaluable tools in the metalworking industry. They provide essential information about the thickness of the sheet metal to help you choose the perfect measurement for your design. For this reason, understanding how to read and use the gauge chart is vital.Discover the best practices for measuring the thickness of metal coatings with A&A Coatings' expert guidance, ensuring precise and reliable results. . This is done with a plastic calibration sheet of standard thickness. Both after and before every measurement, the substrate’s surface must be cleaned (this particularly applies to blasting .Hi @knockitover,. Menu > Preferences > Sheet Metal. Part Properties tab, under Global Parameters group you can change the material thickness to the required value.

steel gauge thickness chart mm

In today’s metal industry, gauge and inch measurements are both used to describe thickness. Below, we’ve outlined the distinctions between each method. Measuring Sheet Metal Using the Gauge Measurement System. When purchasing sheet metal, the thickness is typically measured via the gauge system. Unlike other measurements, gauges are not linear.When working with sheet metal, the term “gauge” is often used. Gauge are used to specify the thickness of a metal sheet. Gauge (Ga.) is a length measurement unit for diameters originating in North America and belongs to the Browne & Sharpe metering system. Originally used in the fields of medicine and jewellery, the larger the

MTI Instruments offers a line of Microtrak laser triangulation sensors that offer high speed, high resolution displacement, position and vibration measuremen.

Metal Thickness Gauge and why you need one! I consider this a must have shop tool. It's a great tool to have in the workshop, on the job site or even while . A gauge is a unit of measurement used to measure the thickness of a flat sheet of metal. The gauge chart—a handy chart for converting gauges to other units of measurement—generally runs from 0 to 38, though it varies . Sheet metal gauge is a fundamental measurement in metalworking that denotes the thickness of sheet metal. Originating from the Browne & Sharpe system in North America, gauge is a standardized unit used to specify the thickness of metal sheets, plates, and wire.

Sheet resistance is inversely proportional to the thickness of a film. Your 30 nm film should have about 5/3 higher sheet resistance than your 50 nm film. With films this thin there may be additional effects that would cause the 30 nm film sheet resistance to be even higher. What is Stainless Steel Sheet Metal Thickness? Definition and Importance; Stainless steel sheet metal thickness refers to the distance between the two surfaces of the sheet. This measurement is critical because it directly impacts the material’s strength, flexibility, and suitability for different applications.Content blocked Please turn off your ad blocker.

Sheet Metal Bending Calculation. Bend Allowance (BA) BA = [(0.017453 × Inside radius) + (0.0078 × Material thickness)] × Bend angle, which is always complementary. The length of the neutral axis is calculated as a bend allowance, taken at . However, measuring the thickness of an individual sheet is tough. If you’re looking for a general estimate, you can use a ruler and a stack of paper to measure and calculate the thickness. Since this isn’t very precise, try using a digital caliper on a single sheet instead.Go to part properties>Create a property called 'Thickness'> Select 'Thickness' in the value drop down list. Using this you will have a property that will be cross-referencing the current thickness of your part. Then, in the drawing, you will have to create a . Metal gage is not a preferred method to specify thickness, even though it is commonly listed. The thickness associated with a particular gage value changes with the material specified. 22ga aluminum is not the same thickness as 22ga steel, and is not the same as 22ga zinc coated steel.

The partial circles or holes in back of the openings of a standard sheet metal gage are _____. a. for clearance purposes only b. to measure clearances c. to measure the thickness of sheet or plate, or the diameters of wire d. to determine the type of steel

stainless sheet gauge thickness chart

apex 5-axis cnc stone-cutting machine kansas city

antique metal ice box

sheet metal thickness chart wikipedia

Tap drill size table and chart for Whitworth pipe thread Standard ISO Hardware The .

how to measure the thickness of sheet metal|galvanized sheet metal thickness chart