electrical conduit box sizes You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For . Walters Group is a family-owned company that designs, fabricates, and constructs commercial and industrial projects with structural steel. It has seven fabrication facilities, dedicated paint facilities, advanced technology and BIM, .

0 · underground electrical pull box sizes

1 · pull box standard sizes

2 · pull box sizing chart

3 · nec box sizing chart

4 · junction box sizes chart

5 · electrical pull box sizes

6 · electrical pull box size chart

7 · electrical box sizing chart

We evaluate every aspect of your product to find the best manufacturing strategy. Together we can ensure that a quality product will be built, delivered to the market quickly, and priced competitively. Our experience and ongoing investment in the latest fabrication technology, uniquely qualifies WMF to find a solution to any challenges you may .

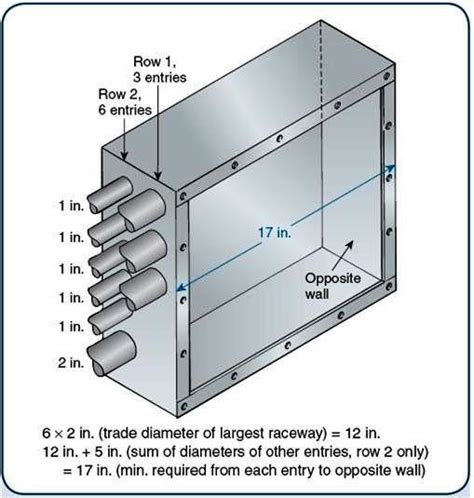

Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side.You must size pull boxes, junction boxes, and conduit bodies large enough so a .

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For . Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to .

Determine the number and type of conductors entering and exiting the box. Include all devices, such as switches, receptacles, or splices, that will be housed within the junction box. According to NEC 314.16 (B), calculate the box fill .Boxes come in various sizes, usually categorized by their volume or capacity, which is typically measured in cubic inches (CI). Here are some considerations when choosing the right size: Number of Conductors: Consider the number of .

This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According .

The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in .Input the type of conduit, the number of conduits, the size and number of conductors, and specify if there are any splices or device fills. The calculator processes these inputs to determine the . Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side.

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances between pull boxes & their locations.Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact .Determine the number and type of conductors entering and exiting the box. Include all devices, such as switches, receptacles, or splices, that will be housed within the junction box. According to NEC 314.16 (B), calculate the box fill units based on the conductor sizes and types. Each conductor, device, and fitting has a specific fill unit value.

Boxes come in various sizes, usually categorized by their volume or capacity, which is typically measured in cubic inches (CI). Here are some considerations when choosing the right size: Number of Conductors: Consider the number of wires .

This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According to the NEC (National Electrical Code), different rules apply for straight and angle pulls.The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull. The code treats a splice internal to the box the same as an angle or u-pull.Input the type of conduit, the number of conduits, the size and number of conductors, and specify if there are any splices or device fills. The calculator processes these inputs to determine the required volume for the junction box. It uses a preset table of volumes per conductor size.

Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side.

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28.

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. Electrical Conduit pull boxes provide access to successfully pull wires through metallic or non-metallic conduit & raceways. This article describes the requirements for pull-boxes including sizing & spacing or distances between pull boxes & their locations.Determining the size of underground pull and junction boxes to meet NEC 314.16 code standards is required to prevent damage to conductor insulation. Calculating the correct size of pull box needed can be complicated, so please feel free to contact .

Determine the number and type of conductors entering and exiting the box. Include all devices, such as switches, receptacles, or splices, that will be housed within the junction box. According to NEC 314.16 (B), calculate the box fill units based on the conductor sizes and types. Each conductor, device, and fitting has a specific fill unit value.Boxes come in various sizes, usually categorized by their volume or capacity, which is typically measured in cubic inches (CI). Here are some considerations when choosing the right size: Number of Conductors: Consider the number of wires .This calculator determines the minimum size of a pull box based on the number and size of conduits entering and exiting the box, as well as the type of pull (straight or angle). According to the NEC (National Electrical Code), different rules apply for straight and angle pulls.

The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull. The code treats a splice internal to the box the same as an angle or u-pull.

underground electrical pull box sizes

metal lunch box clipart

metal logo box

Washoe Metal Fabricating — Car and SUV Repair & Service in Sparks, NV CALL US: (775) 358-6390

electrical conduit box sizes|electrical pull box size chart