basic metal fabrication Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, . SHEET STEEL: Either hot or cold rolled sheets produced on continuous sheet mill where the minimum width produced is 24. Sheet coils when slit to narrower widths is called slit sheet. SHOT BLASTING: Cleaning surface of metal by air blast, using metal shot as an abrasive.Exactly, you can install Sonar, play around with it, and just turn it off if you don't like how it modifies the sound. I went for the wired version because the wireless one does not supports 96Khz/24bit, I guess that's the reason why they didn't place a "Hi-Res" sticker onto the .

0 · working with sheet metal basics

1 · what is a fab shop

2 · types of sheet metal fabrication

3 · steel fabrication basics

4 · sheet metal design and fabrication

5 · materials used for fabrication

6 · how to make fabrications

7 · basics of sheet metal fabrication

But if you want a single box to accommodate multiple circuits, the size is your only limitation. You can use as many circuits as you want if the box is large enough to hold them. Small boxes are dangerous because they compel you to bend the wires, which .

Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, . See moreChoosing a custom metal fabrication shop or custom metal manufacturer that will best fulfill a project’s needs is an important decision that can affect the manufacturing rate, production quality, and cost-effectiveness of a given project. To help in the selection . See more

This guide provides a basic understanding of metal fabrication, the different methods, and considerations for choosing a fabricator. For more . See more Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, .The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and .

You should know a few basic things if you're new to sheet metal fabrication. In this article, we'll go over the basics of how to work with sheet metal, from cutting and bending to welding and finishing. In this guide, we’ll explore the key sheet metal fabrication techniques, their advantages, and their applications. By the end, you’ll have a solid understanding of the options available to you, empowering you to make . Discover the ins and outs of steel fabrication from cutting and bending methods to raw material choices. Learn its benefits and why trusting a professional steel fabricator is . Understanding the fundamental processes, tools and terms in the metal fabrication discipline can help ensure a successful project outcome.

Metal fabrication is a multifaceted process that combines technology, skill, and precision to transform raw materials into finished products. Each step, from design and material selection . Metal fabrication is the processing of metals to create various metal objects. The process of metal fabrication can happen in one step or can even take tens of steps, depending on what is required.

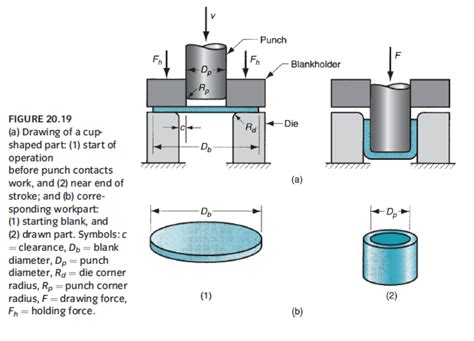

Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, and the materials used in crafting it. Common metal fabrication processes are as follows: Casting; Cutting; Drawing; Folding; Forging; Extrusion; Machining; Punching; Shearing; Stamping; Welding; Casting Metal fabrication is taking a raw material, typically sheets of metal, through a series of processes to create a finished end product. Virtually every industry relies on metal fabrication to operate efficiently, create the tools they need, develop products, etc. Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, showcasing a blend of technical skills and creativity.

The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and assemblies. You should know a few basic things if you're new to sheet metal fabrication. In this article, we'll go over the basics of how to work with sheet metal, from cutting and bending to welding and finishing.

In this guide, we’ll explore the key sheet metal fabrication techniques, their advantages, and their applications. By the end, you’ll have a solid understanding of the options available to you, empowering you to make informed choices for your organization. Discover the ins and outs of steel fabrication from cutting and bending methods to raw material choices. Learn its benefits and why trusting a professional steel fabricator is crucial for project success. Understanding the fundamental processes, tools and terms in the metal fabrication discipline can help ensure a successful project outcome.

working with sheet metal basics

Metal fabrication is a multifaceted process that combines technology, skill, and precision to transform raw materials into finished products. Each step, from design and material selection to cutting, forming, machining, welding, and finishing, plays a crucial role in ensuring the final product meets high standards of quality and functionality. Metal fabrication is the processing of metals to create various metal objects. The process of metal fabrication can happen in one step or can even take tens of steps, depending on what is required.

bare metal chassis

Choosing a metal fabrication method suited to a given project depends on the designed part’s geometry, the product’s intended purpose, and the materials used in crafting it. Common metal fabrication processes are as follows: Casting; Cutting; Drawing; Folding; Forging; Extrusion; Machining; Punching; Shearing; Stamping; Welding; Casting Metal fabrication is taking a raw material, typically sheets of metal, through a series of processes to create a finished end product. Virtually every industry relies on metal fabrication to operate efficiently, create the tools they need, develop products, etc.

Metal fabrication is the art and science of building metal structures by cutting, bending, and assembling processes. This intricate craft involves transforming raw metal materials into pre-designed shapes and products, showcasing a blend of technical skills and creativity.The metal fabrication process encompasses manufacturing techniques like bending and cutting, using an array of advanced equipment to produce complex metal shapes, components, and assemblies. You should know a few basic things if you're new to sheet metal fabrication. In this article, we'll go over the basics of how to work with sheet metal, from cutting and bending to welding and finishing. In this guide, we’ll explore the key sheet metal fabrication techniques, their advantages, and their applications. By the end, you’ll have a solid understanding of the options available to you, empowering you to make informed choices for your organization.

Discover the ins and outs of steel fabrication from cutting and bending methods to raw material choices. Learn its benefits and why trusting a professional steel fabricator is crucial for project success. Understanding the fundamental processes, tools and terms in the metal fabrication discipline can help ensure a successful project outcome.Metal fabrication is a multifaceted process that combines technology, skill, and precision to transform raw materials into finished products. Each step, from design and material selection to cutting, forming, machining, welding, and finishing, plays a crucial role in ensuring the final product meets high standards of quality and functionality.

what is a fab shop

types of sheet metal fabrication

But the good news is you only need to learn a handful of common fabrication phrases to communicate like a true sheet metal services expert. With these words, designers, engineers, and buyers can collaborate optimally and .

basic metal fabrication|working with sheet metal basics