3 4 and 5 axis cnc machines The main difference between 3-axis, 4-axis and 5-axis CNC machining is the range of motion. On 3-axis CNC mills, the cutting tool orientation remains constant throughout the cutting path, while on 4- and 5-axis mills, the . • Sink clips • Fits Elkay and other stainless steel sinks using U channel brackets • For countertops up to 1-1/2-in thickness

0 · small 3 axis cnc mill

1 · axis identification in cnc machine

2 · 3 axis vs 5 mill

3 · 3 axis vertical milling machine

4 · 3 axis hobby milling machine

5 · 3 axis cnc milling machine

6 · 3 axis cnc machine price

7 · 2.5 axis milling vs 3

$39.99

The main difference between 3-axis, 4-axis and 5-axis CNC machining is the range of motion. On 3-axis CNC mills, the cutting tool orientation remains constant throughout the cutting path, while on 4- and 5-axis mills, the . The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two . 3 axis CNC machines: The simplest and cheapest type. Good for cutting flat 2D and 2.5D parts. 4 axis CNC machines: More flexible and accurate. Can drill on sides and cylindrical surfaces. 5 axis CNC machines: The most advanced and expensive type. Can produce complex 3D shapes and angled features.

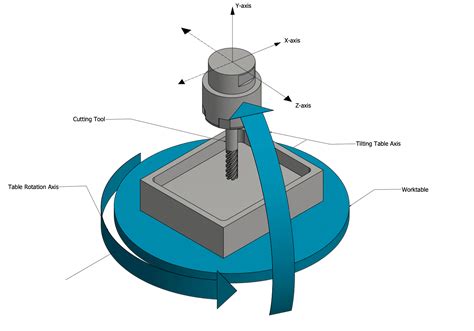

The main difference between 3-axis, 4-axis and 5-axis CNC machining is the range of motion. On 3-axis CNC mills, the cutting tool orientation remains constant throughout the cutting path, while on 4- and 5-axis mills, the workpiece can also move. AN-Prototype summarizes the range of motion for 3-, 4-, and 5-axis milling machines: The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two parts, the more complex the geometry of the final machined part can be. 3-axis, 4-axis, and 5-axis CNC machines use the same fundamental technology. However, they have vast differences in terms of capabilities. Axes of Movement: The movement axes are the primary differentiating factor between the 3, 4, and 5-axis CNC machining.4-axis CNC machines typically have three linear axes (X, Y, Z) and one rotary axis (A or B). This additional axis allows the workpiece to rotate, enabling the creation of more complex shapes and features. 5-axis CNC machines have three linear axes (X, Y, Z) and two rotary axes (A/B and C).

In this guide, we’ll discuss how CNC machines are able to make complex shapes using multiple axes of travel, how these directions are defined, and what that means for your product development goals.

small 3 axis cnc mill

Five axis CNC machining is an advanced CNC machining technology that adds two rotation axes (usually referred to as A-axis and C-axis) to the traditional three-axis (X, Y, Z), allowing the workpiece or tool to move or rotate in five different directions. In this article, we compare and contrast three-axis, four-axis, and five-axis CNC milling machines, including their advantages and disadvantages. Invented all the way back in the 1800’s, modern 3-axis CNC milling machines have come a long way from its earliest form.To provide a better idea of which milling machine and capabilities are best for you, we’ll explain the difference between a few types of machining: 3-axis, 4-axis, and 5-axis. What is 3-axis Milling? For 3-axis machining, the tool can move in three distinct directions independently or simultaneously relative to the material.3-axis CNC Milling Machines include axes that can move along the X-axis, Y-axis, and Z-axis dimensions–pretty basic stuff. A 4-axis CNC machine adds a rotating A-axis, enhancing the typical three-axis setup. This allows for more complex part geometries and .

3 axis CNC machines: The simplest and cheapest type. Good for cutting flat 2D and 2.5D parts. 4 axis CNC machines: More flexible and accurate. Can drill on sides and cylindrical surfaces. 5 axis CNC machines: The most advanced and expensive type. Can produce complex 3D shapes and angled features.

axis identification in cnc machine

The main difference between 3-axis, 4-axis and 5-axis CNC machining is the range of motion. On 3-axis CNC mills, the cutting tool orientation remains constant throughout the cutting path, while on 4- and 5-axis mills, the workpiece can also move. AN-Prototype summarizes the range of motion for 3-, 4-, and 5-axis milling machines: The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two parts, the more complex the geometry of the final machined part can be.

3-axis, 4-axis, and 5-axis CNC machines use the same fundamental technology. However, they have vast differences in terms of capabilities. Axes of Movement: The movement axes are the primary differentiating factor between the 3, 4, and 5-axis CNC machining.

4-axis CNC machines typically have three linear axes (X, Y, Z) and one rotary axis (A or B). This additional axis allows the workpiece to rotate, enabling the creation of more complex shapes and features. 5-axis CNC machines have three linear axes (X, Y, Z) and two rotary axes (A/B and C). In this guide, we’ll discuss how CNC machines are able to make complex shapes using multiple axes of travel, how these directions are defined, and what that means for your product development goals.

Five axis CNC machining is an advanced CNC machining technology that adds two rotation axes (usually referred to as A-axis and C-axis) to the traditional three-axis (X, Y, Z), allowing the workpiece or tool to move or rotate in five different directions. In this article, we compare and contrast three-axis, four-axis, and five-axis CNC milling machines, including their advantages and disadvantages. Invented all the way back in the 1800’s, modern 3-axis CNC milling machines have come a long way from its earliest form.To provide a better idea of which milling machine and capabilities are best for you, we’ll explain the difference between a few types of machining: 3-axis, 4-axis, and 5-axis. What is 3-axis Milling? For 3-axis machining, the tool can move in three distinct directions independently or simultaneously relative to the material.

edinburgh high-quality cnc machining parts suppliers

edf electric meter box

3 axis vs 5 mill

Shop CRAFTSMAN 28-in W x 28-in H x 12-in D Wall-mounted Steel Garage Cabinet in Red in the Garage Cabinets department at Lowe's.com. Proudly made in the USA with global materials in .

3 4 and 5 axis cnc machines|3 axis vs 5 mill