90 degree bend sheet metal When the sheet metal drawing calls for a 90-degree bend with a particularly small bending radius, the sheet metal should first be grooved and then bent. Special press brake tooling, such as punches and dies, can also be used.

The basic machine uses 110v to run the controller. You can use the same circuit (but a second outlet) to run a small transformer for the monitor. You might think the USB .

0 · sheet metal bending strength

1 · sheet metal bending drawing

2 · sheet metal bending diagram

3 · sheet metal bending chart

4 · sheet metal bending angle chart

5 · radius of regular 90 bend

6 · large radius sheet metal bending

7 · calculate bend radius sheet metal

The board literally folds out of the wall, which is a pretty cool feature, if you ask us. The box is too big for a modern iron, but as one user says, it's for older smaller irons. The box is "lined with metal and vent holes so you can put the warm iron .

Did you size the sheet of metal to take into consideration the stretching of the metal at the bend? If you do a 90-degree bend, the metal will stretch and shrink the thickness of the metal. See more

Improve your metal fabrication with Amada's 88° and 90° bend allowance chart. Get precise results and optimize your process. Download now. Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and . Use SendCutSend’s bending calculator to input your desired material . They apply bend functions to a simple, single-bend part, bent past 90 degrees complementary, to show how the complementary or included angles are applied in the OSSB and ultimately to a layout. The part in Figure 4 is bent .

When the sheet metal drawing calls for a 90-degree bend with a particularly small bending radius, the sheet metal should first be grooved and then bent. Special press brake tooling, such as punches and dies, can also be used.

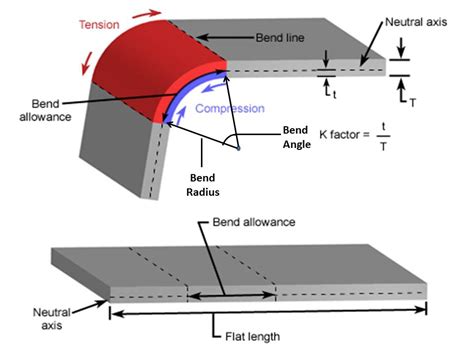

We are going to review three bending scenarios with three different bending angles; 60, 90 and 120, and we will calculate K-Factor, Bend Allowance and Bend Deduction for them. The bending tool has a radius of 30 mm which . To achieve a 90-degree bend, you must overbend the material past the desired bend angle and allow it to return to the desired shape with the springback. Figure 1 shows perhaps one of the simplest die designs that can .

how to evenly distribute objects in a box in illustrator

sheet metal bending strength

It is the most commonly used and widely preferred bending process to bend metal sheets into a V, 90-degree, or acute-angle shape. The process involves using machinery tools called “to die and punch” to bend metals at . Did you size the sheet of metal to take into consideration the stretching of the metal at the bend? If you do a 90-degree bend, the metal will stretch and shrink the thickness of the metal. Improve your metal fabrication with Amada's 88° and 90° bend allowance chart. Get precise results and optimize your process. Download now. Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations.

Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. The calculator also allows you to input flanges. Select material type, thickness, and desired units. Enter your base length. Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.

They apply bend functions to a simple, single-bend part, bent past 90 degrees complementary, to show how the complementary or included angles are applied in the OSSB and ultimately to a layout. The part in Figure 4 is bent to 160 degrees complementary. When the sheet metal drawing calls for a 90-degree bend with a particularly small bending radius, the sheet metal should first be grooved and then bent. Special press brake tooling, such as punches and dies, can also be used.

We are going to review three bending scenarios with three different bending angles; 60, 90 and 120, and we will calculate K-Factor, Bend Allowance and Bend Deduction for them. The bending tool has a radius of 30 mm which means that our Inside Bend Radius (R) is 30 mm. Let’s start with 90 degrees bend which is the most simple scenario. To achieve a 90-degree bend, you must overbend the material past the desired bend angle and allow it to return to the desired shape with the springback. Figure 1 shows perhaps one of the simplest die designs that can achieve a 90-degree bend.

It is the most commonly used and widely preferred bending process to bend metal sheets into a V, 90-degree, or acute-angle shape. The process involves using machinery tools called “to die and punch” to bend metals at desired angles or shapes. Did you size the sheet of metal to take into consideration the stretching of the metal at the bend? If you do a 90-degree bend, the metal will stretch and shrink the thickness of the metal. Improve your metal fabrication with Amada's 88° and 90° bend allowance chart. Get precise results and optimize your process. Download now.

Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and accurately determine critical parameters for sheet metal bending operations.Use SendCutSend’s bending calculator to input your desired material and the units of measurement for your design to get the calculated bend allowance and bend deduction for your part before sending it to our lasers. The calculator also allows you to input flanges. Select material type, thickness, and desired units. Enter your base length. Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. They apply bend functions to a simple, single-bend part, bent past 90 degrees complementary, to show how the complementary or included angles are applied in the OSSB and ultimately to a layout. The part in Figure 4 is bent to 160 degrees complementary.

When the sheet metal drawing calls for a 90-degree bend with a particularly small bending radius, the sheet metal should first be grooved and then bent. Special press brake tooling, such as punches and dies, can also be used. We are going to review three bending scenarios with three different bending angles; 60, 90 and 120, and we will calculate K-Factor, Bend Allowance and Bend Deduction for them. The bending tool has a radius of 30 mm which means that our Inside Bend Radius (R) is 30 mm. Let’s start with 90 degrees bend which is the most simple scenario. To achieve a 90-degree bend, you must overbend the material past the desired bend angle and allow it to return to the desired shape with the springback. Figure 1 shows perhaps one of the simplest die designs that can achieve a 90-degree bend.

how to elevate boxes in storgae metal

sheet metal bending drawing

how to drill through metal sheet

sheet metal bending diagram

Sheet Metal Workers fabricate, assemble, install, and repair sheet metal products and equipment, such as ducts, control boxes, drainpipes, and furnace casings.

90 degree bend sheet metal|sheet metal bending drawing