sheet metal bend relief SHEET METAL Training with TOBY: www.TooTallToby.com/training More SOLIDWORKS SHEET METAL videos: https://youtube.com/playlist?list=PLzMIhOgu1Y5deswXMjjl9J. Metal Enclosure, IP65 Waterproof Electrical Box for Indoor and Outdoor Projects, Includes Mounting Plate and Wall Bracket 350×250×150mm (14"×10"×6")

0 · solidworks sheet metal relief cut

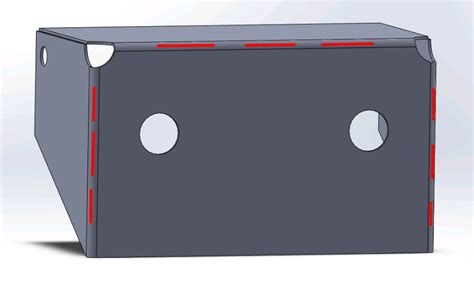

1 · solidworks sheet metal corner relief

2 · solidworks sheet metal bend relief

3 · sheet metal fabrication design guide

4 · sheet metal corner relief chart

5 · sheet metal bending chart

6 · sheet metal bend relief guidelines

7 · auto relief solidworks sheet metal

MILLAC is the main aluminium extrusion company in the Philippines that had already established consistent, reliable and world-class manufacturing excellence over the years in service. Our country's leading producer and supplier of top .

solidworks sheet metal relief cut

A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. They are a .Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part. Figure "B" shows a part with the edge a sufficient distance . Learn how to design sheet metal parts with bend relief, small holes, hole distortion, and minimum flange widths. The article explains the .

SHEET METAL Training with TOBY: www.TooTallToby.com/training More SOLIDWORKS SHEET METAL videos: https://youtube.com/playlist?list=PLzMIhOgu1Y5deswXMjjl9J.

solidworks sheet metal corner relief

solidworks sheet metal bend relief

In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced techniques and real-world applications that contribute to successful fabrication endeavors.Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Although they are small features, leaving them out can cause stress to concentrate at the bend line, resulting in deformed holes and .Bend Relief in Sheet Metal Bend Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Recommended Bend Relief height is always more than two times of sheet .

When bending a piece of sheet metal, the residual stresses in the material will cause the sheet to springback slightly after the bending operation. Due to this elastic recovery, it is necessary to over-bend the sheet a precise amount to .

What Is Bend Relief? In sheet metal, a bend relief is an incision cut along the sides of a planned bend. Though bend relief lengths and widths vary between projects, they all share a common goal: preventing tearing and part . SHEET METAL Training with TOBY: www.TooTallToby.com/training More SOLIDWORKS SHEET METAL videos: https://youtube.com/playlist?list=PLzMIhOgu1Y5deswXMjjl9J.When bending a piece of sheet metal, the residual stresses in the material will cause the sheet to springback slightly after the bending operation. Due to this elastic recovery, it is necessary to over-bend the sheet a precise amount to .

For example, when you have a Sketched Bend in the FeatureManager design tree, the Sketched Bend feature is the sheet metal feature, and SketchBend is the individual bend that is absorbed in the Sketched Bend feature. To change the type and size of a relief cut for a feature bend: 1. No Bend Relief . In sheet metal design, bend relief refers to a small cut or notch made at the intersection of two bend lines. Its purpose is to prevent material deformation, tearing, and other issues during the bending process.

automotive metal fabrication service portland

Tab - Add a tab to a sheet metal flange. Bend - Bend a sheet metal model along a reference line, with additional bend control options. Make joint - Convert the intersection of two walls into a joint feature, either a bend (walls joined by cylindrical geometry) or a rip (small gap between two walls). Corner - Modify a corner type and relief scale.

When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Hem - Create a hem for each edge/face selected, on an existing sheet metal part.; Tab - Add a tab to a sheet metal flange.; Bend - Bend a sheet metal model . Tab - Add a tab to a sheet metal flange. Bend - Bend a sheet metal model along a reference line, with additional bend control options. Make joint - Convert the intersection of two walls into a joint feature, either a bend (walls joined by cylindrical geometry) or a rip (small gap between two walls). Corner - Modify a corner type and relief scale.For example, when you have a Sketched Bend in the FeatureManager design tree, the Sketched Bend feature is the sheet metal feature, and SketchBend is the individual bend that is absorbed in the Sketched Bend feature. To change the type and size of a relief cut for a feature bend:• Lanced (sheared) features with zero cut relief are possible but require high-cost tooling. [email protected] | 607.227.7070 | www.incodema.com Cut relief between external features. Internal bend relief must extend to the limit of the bend radius. Cut relief around internal features. External bend relief must extend to the limit

Bend Relief. Synchronous sheet metal is pretty cool, even cooler than just normal synchronous modeling, if you’ll excuse that word. For example, if you make a partial flange as above using all the defaults, the software makes relief cuts at the end of the bends, as shown to the right. If you move the flange to the inside of the part, the .Bend Relief. When sheet metal makes a transition from a bend to a flat surface, or to another bend, it tends to tear depending on the geometry of the boundary. As a general practice, relief is provided to the flange for ease of bending operation. Benefits of Bend Relief.

In an open sheet metal part with bend reliefs, click Flexible Modeling > Edit Bend Relief. . The new bend relief was created as a rectangular relief, Up to Bend with a width of 0.50. 4. To set the method for closing the relief, select an option from the Removal method list.Use the Corner Relief PropertyManager to apply corner treatments to a folded sheet metal body that persist in the flattened state. To open the Corner Relief PropertyManager: Do one of the following: . Tangent to bend . Makes the corner relief tangent to the inside bend edges when Centered on bend lines is selected. Tear. Creates a tear corner . When a sheet metal model is active (in the process of being created or edited), additional tools are available: Flange - Create a wall for each edge selected, connected to the selected edge with a bend.; Hem - Create a hem for each edge/face selected, on an existing sheet metal part.; Tab - Add a tab to a sheet metal flange.; Bend - Bend a sheet metal model .

Tab - Add a tab to a sheet metal flange. Bend - Bend a sheet metal model along a reference line, with additional bend control options. Make joint - Convert the intersection of two walls into a joint feature, either a bend (walls joined by cylindrical geometry) or a rip (small gap between two walls). Corner - Modify a corner type and relief scale.

Use the Corner Relief PropertyManager to apply corner treatments to a folded sheet metal body that persist in the flattened state. Parent topic Using Sheet Metal Tools Search 'Corner Reliefs and Bend Transitions' in the SOLIDWORKS Knowledge Base.

Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc. . Bend Relief. Bend reliefs are necessary. To get the best outcome, it is advisable to make not only a small laser cut incision but an actual cutout on the sides of the flange-to-be – a bend relief. The . Tab - Add a tab to a sheet metal flange. Bend - Bend a sheet metal model along a reference line, with additional bend control options. Make joint - Convert the intersection of two walls into a joint feature, either a bend (walls joined by cylindrical geometry) or a rip (small gap between two walls). Corner - Modify a corner type and relief scale.

Yes, it would be great if such bend relief shape can be included in Sheet Metal environment. The tricky thing here is that the relief shape may be complicated when adjacent edges are not straight. Or, there are multiple bends involved. At the moment, you can either create punchtool or create circular cuts in flat pattern. Many thanks! Bend relief is a notch made at the outer edge of the sheet metal, which is bent and prevents tearing or distortion during bending. Its major purpose is to ensure that the material is able to deform and move without restrictions thus minimizing high stress in the centre bend area.Learn about how sheet metal bending works from the experts at OSH Cut. Contact us for more information today! . Missing or Insufficient Bend Relief. Bend relief allows two bend regions to connect on the ends, without "fighting over" which bend gets to deform the metal. In the flat pattern below, two different bends at 90 degrees meet on the .Sometimes this notch is used for parts with a large bend radius. The previous notches can be used with a large bend radius if a relief hole or slot is used in the corner (see Bend Reliefs). If no relief distance is called out on the print and you are using a large bend radius with this type of notch then to be safe use a minimum distance of the .

Plasma cutting bend relief cuts for hand bending sheet metal. I'm an absolute 100% newbie to CNC plasma cutting, CAD, and solidworks. I tried Freecad, and Fusion 360, but Solidworks feels like it has just "clicked" for me, particularly with 3D parts, which is what most of my needs are. I've designed a few sheet metal parts, and I'm enjoying . Tab - Add a tab to a sheet metal flange. Bend - Bend a sheet metal model along a reference line, with additional bend control options. Make joint - Convert the intersection of two walls into a joint feature, either a bend (walls joined by cylindrical geometry) or a rip (small gap between two walls). Corner - Modify a corner type and relief scale.

Set your bend radius lower in the "sheet metal rule" - in my example .25MM was the sweet spot for 1MM steel. This will be specified for the material you're choosing to build from. When you use the "flange" tool, you can click the "bend override" option and set .Sheet metal bend radius: This guide details bending heights, directions, tool interference, bend reliefs, and tolerance stackup. . Other factors such as bend relief geometries and flange offsets will complete your design choices and yield a quality design that is suitable for production. It is always recommended to reach out to the intended .

sheet metal fabrication design guide

Our company is a union-affiliated general contractor deeply embedded in the heart of Southern California. Our specialization is in delivering cutting-edge Heating, Ventilating, and Air Conditioning (HVAC) solutions tailored to diverse requirements.

sheet metal bend relief|solidworks sheet metal corner relief