cnc router parts rack and pinion development The forces on our pinion gears are well within spec. I haven't seen any . There are various ways of extending a lighting circuit to add lighting points: You could run a spur from the last ceiling rose in a loop-in circuit; run a spur from an existing junction box, or from a new junction box; or run a fused spur from a socket outlet.

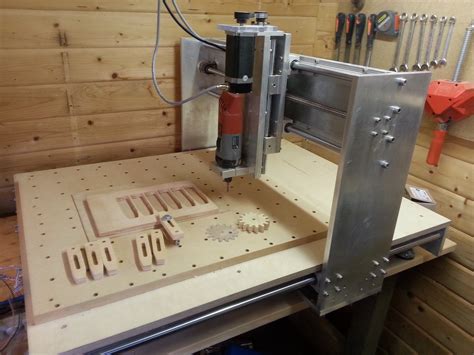

0 · diy cnc router plans

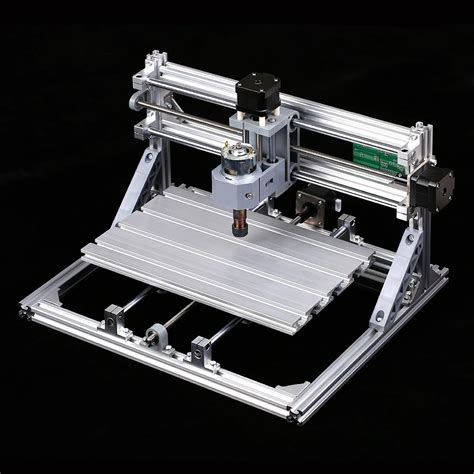

1 · diy cnc router kit

2 · cnc 5x10 router build

Clear, easy-to-read wiring diagrams for connecting multiple receptacle outlets in a row, including GFCI and Duplex Receptacles.

diy cnc router plans

Additionally, since a gear reduction is almost mandatory for a rack and pinion system, I decided to make this system compatible with NEMA 23 motors to take advantage of .The forces on our pinion gears are well within spec. I haven't seen any .CNC Router Parts Rack and Pinion Development. If this is your first visit, be . The forces on our pinion gears are well within spec. I haven't seen any unnecessary wear on the pinion gear. What company are you using for the pinion gears and .

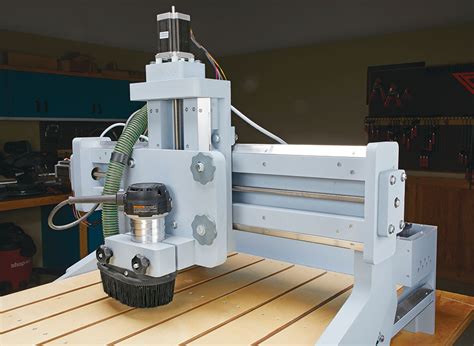

CNC Router Parts Rack and Pinion Development. If this is your first visit, be sure to check out the FAQ by clicking the link above. You may have to register before you can post: .DIY CNC Router Build (large Format 5x10ft, Rack and Pinion): This is a not so little summary of the build of my homemade CNC router, aka The Overpass. This instructable is more of a . I used C-Beams from Open Builds with the 'pro' rack and pinion stuff from the CNC Router Parts store. The rack has a flange that you can screw into V-Slot with M5 screws + .

Compare rack and pinion, belt drive, and ballscrew systems for CNC machining. Learn about the pros and cons of each option for your application. Explore now! Here is a closer look at how rack and pinion drive systems work, their advantages and shortcomings, and how they compare to ball screw technology. How a rack and pinion drive system works. As the name . DIY CNC Router Table Machines; CNC Router Parts Rack and Pinion Development; If this is your first visit, be sure to check out the FAQ by clicking the link above. You may have to register before you can post: click the register link above to proceed. To start viewing messages, select the forum that you want to visit from the selection below. . DIY CNC Router Table Machines; CNC Router Parts Rack and Pinion Development; If this is your first visit, be sure to check out the FAQ by clicking the link above. You may have to register before you can post: click the register link above to proceed. To start viewing messages, select the forum that you want to visit from the selection below. .

DIY CNC Router Table Machines; CNC Router Parts Rack and Pinion Development; If this is your first visit, be sure to check out the FAQ by clicking the link above. You may have to register before you can post: click the register link above to proceed. To start viewing messages, select the forum that you want to visit from the selection below. . DIY CNC Router Table Machines; CNC Router Parts Rack and Pinion Development; If this is your first visit, be sure to check out the FAQ by clicking the link above. You may have to register before you can post: click the register link above to proceed. To start viewing messages, select the forum that you want to visit from the selection below. .The R&P system is based on a pinion with a 1" pitch circle. The total linear distance traveled per revolution of the pinion is thus 3.14159". With the 3:1 reduction, this means that the distance traveled per motor revolution is 3.14159 / 3, or 1.0472".

There are 4.54 N per pound, or 0.283 N per oz. So 2.1 N*m of torque translates to about 18.2 lb*in, or 290 oz*in. So torque at the pinion gear is about 3X this, or 870 oz*in.Possibly a third 6' rack for my Y axis if I have any whipping issues with the 57" long 1/2-10 5S ACME screw . A 53" rack might be long enough but it depends on whether the drive pinion will or will not run off the ends of the rack. I don't want to limit the Y .

DIY CNC Router Table Machines; CNC Router Parts Rack and Pinion Development; If this is your first visit, be sure to check out the FAQ by clicking the link above. You may have to register before you can post: click the register link above to proceed. To start viewing messages, select the forum that you want to visit from the selection below. .

DIY CNC Router Table Machines; CNC Router Parts Rack and Pinion Development; If this is your first visit, be sure to check out the FAQ by clicking the link above. You may have to register before you can post: click the register link above to proceed. To start viewing messages, select the forum that you want to visit from the selection below. .

CNC Router Parts Rack and Pinion Development. Hi all, Many people have been asking about the new rack and pinion system I'm developing, so this thread will be a discussion of the project. Note, this thread will not be used as an advertisement -- just a log for the development of this component. For any updates on pricing or availability of this .

Hi all, Many people have been asking about the new rack and pinion system I'm developing, so this thread will be a discussion of the project. Note, this thread will not be used as an advertisement -- just a log for the development of this component. For any updates on pricing or availability of this project commercially, please contact me through my website. CNC Router Parts Rack and Pinion Development. Printable View. Show 40 post(s) from this thread on one page . A simple and cost effective means to get people into large format cnc with R&P. . 06-21-2009, 07:44 PM. solodex2151. In addition, I have been working on a 4'x4' machine that utilizes the Rack and Pinion system for the X and Y axis. I .It still contacts the rack and there is zero play in it, but it get's rid of the rack bottoming out on the pinion and making all that noise. For the other side either I will order another stepper mount and put it on the other side and do the same thing, or will drill and tap a whole to put some sort of cam I can adjust the r&p down a bit with.Companies like avid cnc use rack and pinion drives on their smaller 2'x4' and 4'x4' machines just to maintain commonality with their larger configurations (4x8, 5x10!) not because rack and pinion is the right choice for the smaller machines they sell. I just went through the math for the 4'x4' configuration of the router I'm building.

That pinion shaft is say 1.5" long. Pinion on one end and supported by a single bearing on the other. The pinion is driving the axis, hardest during rapid acceleration and deceleration. It is more than just the spring tension. And that is not saying anything about the belt tension and transmission. Greg

diy cnc router kit

DIY CNC Router Table Machines; CNC Router Parts Rack and Pinion Development; If this is your first visit, be sure to check out the FAQ by clicking the link above. You may have to register before you can post: click the register link above to proceed. To start viewing messages, select the forum that you want to visit from the selection below. . Hi all, Many people have been asking about the new rack and pinion system I'm developing, so this thread will be a discussion of the project. Note, this thread will not be used as an advertisement -- just a log for the development of this component. For any updates on pricing or availability of this project commercially, please contact me through my website.

So in order to not have to get long ballscrews, i am considering rack and pinion systems, either 3D printed ones, or machined in wood or plastic. . Both the CNC routers I operated at my old job were rack and pinion for both x and y axis. (Torch mate routermaye) . I'm a bit partial as mine's full of Avid parts, but the RP has never been an . Forum - The expert community . Category overview ; List of all discussion forums ; The 100 latest forum topics ; IndustryArena.TV . New and popular video trendsGear Rack, 52" Gear Rack, 39" (1 meter) Simply mount rack to the extrusion underneath the rail using our Rack Clamps and combine lengths of rack to get the travel you desire. MACH Settings for R&P: The R&P system is based on a pinion with a 1" pitch circle. The total linear distance traveled per revolution of the pinion is thus 3.14159". Hi all, Many people have been asking about the new rack and pinion system I'm developing, so this thread will be a discussion of the project. Note, this thread will not be used as an advertisement -- just a log for the development of this component. For any updates on pricing or availability of this project commercially, please contact me through my website.

All, I think the wait is over -- I'm quite pleased with the performance of the new rack and pinion system, and am ready to put it on sale. As a recap, the changes to the test setup include: 1) While this isn't part of the R&P per se, I got off my butt and used a piece of cold rolled steel for the test rail -- no squeaking now, and the motion is substantially smoother.The R&P system is based on a pinion with a 1" pitch circle. The total linear distance traveled per revolution of the pinion is thus 3.14159". With the 3:1 reduction, this means that the distance traveled per motor revolution is 3.14159 / 3, or 1.0472". How a rack and pinion drive system works. A Rack and Pinion Drive. A rack and pinion is a type of linear actuator consisting of a circular gear (the pinion) that engages with a linear gear (the rack) to convert rotational motion into linear motion.. CNC Rack and Pinion. Rack and pinion drives are commonly used in CNC machines, such as CNC plasma tables and .

Im working on building a gantry rack and pinion cnc with servo motors. Ill be milling steel and aluminum parts and is 10;1 gear ratio or for the 750w motors, also a servo with rotate the workpiece horizontally at 10:1, iIdont need to move it at insane spe8ds though. Any thoughts on this as im am using freecad. thanks Hi all, Many people have been asking about the new rack and pinion system I'm developing, so this thread will be a discussion of the project. Note, this thread will not be used as an advertisement -- just a log for the development of this component. For any updates on pricing or availability of this project commercially, please contact me through my website.CNC Router Parts Rack and Pinion Development. A ball screw drive is used for the shorter Z-axis, unlike the PRSalpha which uses rack and pinion for Z-axis as well.2 inches a minute.What you really need is accuracy.A typical automatic rack-and .

adirondack sheet metal

In this beginners DIY electrical guide i will be showing you how to wire up two way light switches. I will show you step by step how to install a two way lig.

cnc router parts rack and pinion development|cnc 5x10 router build