should junction box be flush with drywall This is a quick tutorial that shows you how to mount an electrical box to be flush with drywall. Hi! fuse # XXXXX or F421 in the battery junction box, which is located in the trunk, under the spare tire mat, is the fuse for your drivers seat. It is a 20 amp fuse and the number .

0 · splicing wire inside wall

1 · splicing electrical wires behind walls

2 · in wall splice kit legal

3 · hidden junction box in wall

4 · extending romex behind drywall

5 · drywall patch over electrical box

6 · are junction boxes legal

7 · approved in wall wire splice

Manufacturer of CNC Router Kits for hobbyists, woodworkers, and craft enthusiasts.

boxes should be flush with outside of drywall, however i believe you're allowed 1/4 if they are non-metallic. wait around for one of the Licensed guys, they'll know the specific code rules for this If you’re installing an interior box, use screws or nails to attach the box to a stud, positioned so that the face of the box is flush with the drywall. Exterior boxes should be attached with screws; the back of the box should .

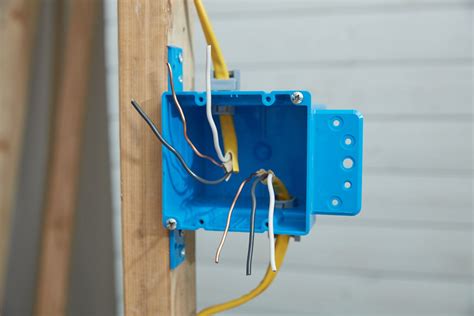

This is a quick tutorial that shows you how to mount an electrical box to be flush with drywall. Installing electrical boxes flush with the drywall is essential. When mounting electrical boxes, the exterior edges should maintain a 1 / 4 -inch depth from the drywall’s face . This way, the outlet will be flat with the wall, reducing . When you install an electrical box, make sure it is flush with the surface of this drywall strip; this will ensure the boxes are at the proper depth when the walls are finished. Most residential drywall is 1/2- or 3/8-inch thick, .

The front edge of the box must be flush with the finished wall surface, usually 1/2-inch-thick drywall. Some boxes have depth gauges. You can use a scrap of drywall to position the box. It is illegal to put drywall over an electrical outlet or junction box with electrical wires connected or terminated inside the box. If the electrical outlet box is empty or the wire runs through it without terminating, you can cover it .

Best for: Increasing box capacity and making boxes flush with surfaces; Box extenders, or extension rings, are installed onto the front of electrical boxes to increase the box capacity or flush the box with the drywall .

Should Outlets Be Flush With Drywall? It’s best if the box for the outlet is as flush with the drywall as possible. This provides for the best and safest fit when you install the cover. Don’t allow the box to be more than 1/4″ inch recessed . This is a quick tutorial that shows you how to mount an electrical box to be flush with drywall. It is a very simple process, and you can have your electrica. This is handy to know about! (And why I should have kept my mouth shut to begin with) Sorry for the bad advice. Out of curiosity, why must junction boxes be flush? I know they need to be, but I don't know why. (Other than code, which is .

Yes, the oven fits perfectly when pushed flush against the back wall (sans faceplate). The rear of the oven is flat with no openings, and there should be no problem installing it flush against the wall. The junction box is complicated by .

You should be more worried about her driving in a car. If that’s your concern, you should ask how to fix it and not “who to call”. There’s a lot more dangerous things that happen in construction than this. Like, basically everything. Your options are: 1 re-pull the wire or have the box in a less conspicuous place.I’m adding a new light switch and there’s probably ~1/4” of paint on top of the drywall. Should I get a junction box that’s flush with the drywall + paint, or a junction box that goes only until the drywall? Drywall is 1/2” thick. Bonus points if anyone can suggest a . Should junction boxes be covered? No matter where the junction box is located, it is important to cover it. When wires are twisted together, resistance to the flow of electricity can be created. . Does electrical box have to be flush with drywall? The front of the box needs to be flush with the wall. There is a way to position the box using a . Junction boxes are sized according to how many wires they can hold—because, among other things, an overstuffed junction box is a fire hazard. . positioned so that the face of the box is flush with the drywall. Exterior boxes should be attached with screws; the back of the box should have small holes for that purpose. .

Should a junction box be flushed with drywall quora electrical basics all homeowners know family handyman tips for installing bo in walls installation advice impress your customers and the taper designmod llc streamline design flush home efficiency guide extenders this 83 cent piece of plastic is amazing an outlet how to extend after tiling fix .

I have a flush mount breaker panel in my garage, in an uninsulated but finished wall. I want to get a few breakers added for shop needs, but have a question on adding a junction box. Can I add a 1" piece of conduit to connect a junction box 1 stud bay over from the main breaker panel to make it easy to pull future wires?If an electrician installed the box then yes he screwed up, electrical code requires the box be no more than 1/4" behind the finished surface (ideally it should be flush), and your box sits just past the back side of the drywall so you're about 1/2" back. You can move or extend them so the boxes are flush with the drywall when you're finished, so you can access the wiring by removing the cover. With a drop ceiling, opening a ceiling tile for access is not considered "removing" part of the building, so you can have junction boxes above the drop ceiling.

Somehow I need to make that transition for the conduit from behind the drywall to conduit on the surface of the drywall. I believe a junction box is the right way to do this. The obvious solution is a surface mount junction box and have conduit enter it from the back, turn in the box, and come out the side to continue on the rest of the way .

The box looks like this type of adjustable depth box. Try tightening the screw but if the box doesn't move you should cut away adhering drywall mud or calk, until it does move. Given the metal bracket which supports the box it is surprising that it is not square to the wall.

This way, when my second layer of 5/8" drywall goes up, it will be flush. I don't have enough depth with the boxes I am using to go out 1 1/4", so I am wondering if I can extend it 1 1/8" instead. This means the box will be recessed into the wall by 1/8" and I am wondering if that is okay. I don't want to install a box extender for just 1/8". Drive the box's nails into the stud or joist. If the box attaches with a flange, drive screws or nails to anchor the box. Project tip: If desired, use a mud ring to attach the box. Adapter rings, also called mud rings, are typically 1/2 . Securing Cables Article 334.30 states that cables coming out of the junction boxes should be secured within 12 inches of the box in all boxes equipped with cable clamps. These cable clamps are not to be removed. 314.17(C) states that .

Remove existing box Open up hole in drywall to fit new fixture (hopefully the hole isn't too large already . Hope that the light and its junction box fit up there with that ceiling joist in the way. . I'd cut off the heads with a Dremel tool, remove the box and .Can I drywall sparkle over this junction box? We took a fluorescent ceiling light off and are planning to put a more modern light in and discovered that the previous owners moved the wires for the light very crudely just adjacent to the junction box. If you're installing new boxes or otherwise need to adjust existing boxes, by all means set them in the right position. However, if the existing boxes were well-placed originally it may not be necessary to do any additional work to bring them to the new drywall surface. From 2017 NEC: 314.20 Flush-mounted Installations.

Agreed. This appears to assume you'll be running a wire through a hole in the ceiling, and the base of the fixture acts as a junction box. I don't think that's to code, but I've also seen ceiling fans that make the same assumption (with respect to wiring, not load support).. But, if the center of this fixture can be placed over the ceiling junction box, with one screw into a joist, I wouldn't .Then mount an octagon box to that. If you need a deeper box. Buy a box extension. Should be near the electric boxes. You can use plastic if you wish. Set your brace in the wall so your box sits flush or slightly behind the exterior sheathing. You will need to kill power to push the wires into the box as well as connect the fixture. OK, get some Madison 2-gang boxes from Home Depot or Lowe's. They are cheaper than the Arlington brand. They have to be ordered, but if shipped to store they are cheaper than from Amazon. Install them flush with existing wall surface. When you install your tile move then out flush with the tile surface.

splicing wire inside wall

The box/mudring doesn't need to be flush on a non combustible wall finish (like drywall), it can be recessed up to 1/4 inch. This 1/8 inch gap rule applies to how big of a gap is allowed between the edge of the box/mud ring and opening in the finish.

Plunge the blade just outside of the box and cut off the plastic ears (that the nails go through) freeing the now-circular box to be pulled down out of the circular drywall hole. If you need to remove the ears as well, you now have plenty of room to maneuver the same tool between the ears and the joist and cut the nails flush with the side of .I 2nd this but instead of using 3/4” drywall (it’s hard to find and really heavy) use 1/2 or 5/8 and use cardboard shims to fir out the studs. They are cheap and easy to staple on. It’s worth getting the drywall surface flush with the existing plaster. Shimming is .(since you cannot buy an lb or junction box behind the drywall) So wondering if there are any junction boxes with have 1 1/4" knockouts at the back I can then run conduit to the panel outside and can then add a mud-ring (if not deep enough) or .

I'd like to move the box inside and replace the light fixture. My question is do I just cut a circular hole in the wall and mount a normal junction box inside? Or do I need a weather-proof junction box? I will be using a wet-rated light fixture. The arrowed light fixture is the one I'm referring too. The other painted one isn't functional.

sheet metal development software

sheet metal drawing software

It’s a separate underground box that receives the treated sewage from your settling chamber and distributes it to your leach field. It ensures even distribution of the treated sewage so as not to flood a particular portion of your property and to avoid contaminated liquid from seeping into the groundwater too quickly.

should junction box be flush with drywall|are junction boxes legal