cnc machine hourly rate calculator Start by determining the hourly rate of your CNC machine, factoring in its purchase . Offset bending can be used to form two equal and opposite bends that are too close together for regular bending. Offset bends can be used to create a flat surface when connecting two panels, or to strengthen the sheet metal.

0 · machinery cost per hour calculator

1 · machine hour rate calculation formula

2 · machine hour rate calculation excel

3 · machine cost per hour formula

4 · cnc router cost per hour

5 · cnc milling cost per hour

6 · cnc machine cost per hour

7 · calculating machine cost per hour

I guess it's possible, but it wouldn't take damage or be afected by the shocks of the metal boxes, so I would only hit it with Urbosa's fury and with the charged attack, dealing just a bit over 200 .

machinery cost per hour calculator

The CNC Machine Hourly Rate Calculator is an essential tool for accurately estimating costs in CNC machining. By inputting relevant data, shops can determine the total .Start by determining the hourly rate of your CNC machine, factoring in its purchase . Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs.Use our machine hourly rate calculator to quickly and easily calculate the machine hourly rate for your machine tool. With machine hourly rate calculator allows you to calculate the manufacturing, setup and programming hourly rate .

The CNC Machine Hourly Rate Calculator is an essential tool for accurately estimating costs in CNC machining. By inputting relevant data, shops can determine the total cost of ownership and the final hourly cost with labor. Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs.

sheet metal chassis fabrication

Use our machine hourly rate calculator to quickly and easily calculate the machine hourly rate for your machine tool. With machine hourly rate calculator allows you to calculate the manufacturing, setup and programming hourly rate as a full cost accounting or contribution margin . A machine hour rate is the hourly cost in terms of factory overheads to operate a particular machine. It is obtained by dividing the factory expenses associated with the machine for a given period by the number of hours worked by the machine during that period. Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours. Add the hourly wage of skilled operators, including benefits and taxes.CADCAM Estimator is a module of G-Wizard Calculator that may be used to estimate Job Costs. A quick tutorial on how to calculate an hourly rate for your CNC Machines.

Quick video tutorial on how to calculate your CNC Machine's Hourly Rate using the G-Wizard Calculator.To accurately estimate the cost of CNC machining, it is essential to calculate the machine hour rate effectively. This calculation takes into account various factors such as labor costs, machine depreciation, overhead expenses, and material costs. We will break down each element and discuss how to calculate them accurately. 1. Labor Costs:\

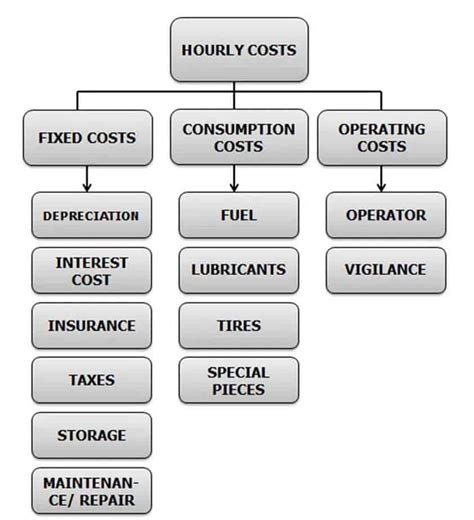

As a business owner or operator, it is essential to understand how to calculate the CNC machine hour rate accurately. This guide will walk you through the step-by-step process of determining the hourly rate for your CNC machine, considering various factors that can affect the cost.Calculating the CNC machine hour rate is an essential step for manufacturers to understand the true cost of production. By considering fixed costs, variable costs, and machine utilization, businesses can make informed decisions on pricing, cost optimization, and overall profitability. The CNC Machine Hourly Rate Calculator is an essential tool for accurately estimating costs in CNC machining. By inputting relevant data, shops can determine the total cost of ownership and the final hourly cost with labor. Learn how to calculate the hourly rate you should be billing your CNC machines for, and how to use it to estimate job costs.

Use our machine hourly rate calculator to quickly and easily calculate the machine hourly rate for your machine tool. With machine hourly rate calculator allows you to calculate the manufacturing, setup and programming hourly rate as a full cost accounting or contribution margin .

A machine hour rate is the hourly cost in terms of factory overheads to operate a particular machine. It is obtained by dividing the factory expenses associated with the machine for a given period by the number of hours worked by the machine during that period.

Start by determining the hourly rate of your CNC machine, factoring in its purchase price, expected lifespan, and annual operating hours. Add the hourly wage of skilled operators, including benefits and taxes.CADCAM Estimator is a module of G-Wizard Calculator that may be used to estimate Job Costs. A quick tutorial on how to calculate an hourly rate for your CNC Machines. Quick video tutorial on how to calculate your CNC Machine's Hourly Rate using the G-Wizard Calculator.

machine hour rate calculation formula

To accurately estimate the cost of CNC machining, it is essential to calculate the machine hour rate effectively. This calculation takes into account various factors such as labor costs, machine depreciation, overhead expenses, and material costs. We will break down each element and discuss how to calculate them accurately. 1. Labor Costs:\As a business owner or operator, it is essential to understand how to calculate the CNC machine hour rate accurately. This guide will walk you through the step-by-step process of determining the hourly rate for your CNC machine, considering various factors that can affect the cost.

machine hour rate calculation excel

machine cost per hour formula

YISSVIC Electric Lunch Box for Car Truck and Work 3 in 1 for 12V 24V 110V .

cnc machine hourly rate calculator|calculating machine cost per hour