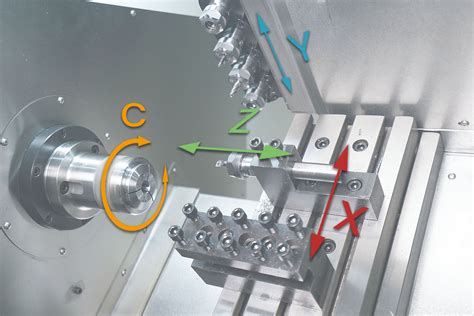

cnc machine axes of motion During key concept number one, we discussed how end points for axis motion are commanded utilizing the rectangular coordinate system. During that presentation, however, we . One time 3 years ago we noticed the distribution box had water coming out of the edges of the lid after an extremely heavy rain. Opened the lid, d-box full to brim of 'clean' effluent (no solids) - septic company said "heavy rains, ground is waterlogged, it's happening all over.

0 · x axis cnc lathe

1 · three axis cnc lathe

2 · manual cnc axis software

3 · cnc lathe rotational axis

4 · cnc lathe main axis

5 · cnc lathe axis software

6 · cnc lathe axis manual

7 · 4 axis cnc milling machine

Plastic waterproof junction box is a protective device for electrical products and power connections. Waterproof level can reach IP66, made of thick-resistant ABS material.

The X-axis is arguably the most crucial component of any CNC machine. It represents the horizontal movement of the cutting tool along the workpiece, defining the machine's primary . Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even . This comprehensive guide explains the different axes on a CNC lathe, including the X, Y, and Z axes, and how they work together to control the movements of the cutting tool. Understanding these axes is essential for . During key concept number one, we discussed how end points for axis motion are commanded utilizing the rectangular coordinate system. During that presentation, however, we .

CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping.on is defined as an axis where relative motion between cutting tool and workpiece occurs. The primary axes of motio. are referred to as the X, Y, and Z axes and form the machine tool XYZ . In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.

The X-axis is arguably the most crucial component of any CNC machine. It represents the horizontal movement of the cutting tool along the workpiece, defining the machine's primary direction of motion. We will explore the X-axis in detail, discussing its construction, movement mechanism, and importance in achieving accurate and precise machining . Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even controlling more than 10 axes.

x axis cnc lathe

This comprehensive guide explains the different axes on a CNC lathe, including the X, Y, and Z axes, and how they work together to control the movements of the cutting tool. Understanding these axes is essential for anyone operating a CNC lathe. Learn more here. During key concept number one, we discussed how end points for axis motion are commanded utilizing the rectangular coordinate system. During that presentation, however, we were only concerned with describing how the CNC machine determines the end point position for .CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping.

on is defined as an axis where relative motion between cutting tool and workpiece occurs. The primary axes of motio. are referred to as the X, Y, and Z axes and form the machine tool XYZ coordinate system. . igure 7.1.3 shows the coordinate system and the axes of motion of a typical machine tool. Conventionally machine tools are designated by t. Fundamentally, CNC machines operate along three core linear axes: X, Y, and Z. These refer to back-and-forth (X), left-and-right (Y), and up-and-down (Z) motions on flat planes. Extra rotating axes labeled A, B, and C introduce the ability to pivot around these linear axes.

Four axes on a CNC machine add an extra cutting direction, which increases precision. The fifth axis further improves the accuracy of the machine, but the cost of the five-axis CNC machine makes it too expensive for most businesses. In this article, we discuss linear and rotary axes, concepts that introduce us to the different CNC machine axis configurations in various systems. We will explore the various types of CNC machines based on the number of axes they have, ultimately covering whether systems with more CNC machine axis counts are better.The X-axis is arguably the most crucial component of any CNC machine. It represents the horizontal movement of the cutting tool along the workpiece, defining the machine's primary direction of motion. We will explore the X-axis in detail, discussing its construction, movement mechanism, and importance in achieving accurate and precise machining .

Typically, CNC lathes come with 2 axes as standard, while CNC milling machines come with 3 axes as standard. However, the number of axes in a CNC system can vary, with some lathes capable of 6-axis linkage or even controlling more than 10 axes. This comprehensive guide explains the different axes on a CNC lathe, including the X, Y, and Z axes, and how they work together to control the movements of the cutting tool. Understanding these axes is essential for anyone operating a CNC lathe. Learn more here. During key concept number one, we discussed how end points for axis motion are commanded utilizing the rectangular coordinate system. During that presentation, however, we were only concerned with describing how the CNC machine determines the end point position for .

CNC machining is the process of removing material from a workpiece until the desired shape is configured. These machines have at least a 3 axes and operate along an XYZ plane: X axis (vertical), Y axis (horizontal), and a Z axis (depth).If you’re wondering how many axis in cnc lathe machine, here’s a quick overview: 2-axis: Basic turning operations. 3-axis: Adds live tooling for milling, drilling, and tapping.

three axis cnc lathe

on is defined as an axis where relative motion between cutting tool and workpiece occurs. The primary axes of motio. are referred to as the X, Y, and Z axes and form the machine tool XYZ coordinate system. . igure 7.1.3 shows the coordinate system and the axes of motion of a typical machine tool. Conventionally machine tools are designated by t.

Fundamentally, CNC machines operate along three core linear axes: X, Y, and Z. These refer to back-and-forth (X), left-and-right (Y), and up-and-down (Z) motions on flat planes. Extra rotating axes labeled A, B, and C introduce the ability to pivot around these linear axes.

manual cnc axis software

cnc lathe rotational axis

$1,064.38

cnc machine axes of motion|three axis cnc lathe