sheet metal attachment method Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre-work. These methods include, mechanical fastening, welding, rivets, brazing and soldering, tongue and . Wiska 1210 Combi Black Junction Box 160 x 140 x 81mm – Premium junction box that includes 10 x M20 threaded membrane entries and M25 knockouts. They also include 4 x membrane cable entries through rear and 4 captive cover .

0 · sheet metal welding process

1 · sheet metal joining technology

2 · sheet metal joining techniques

3 · sheet metal joining screws

4 · sheet metal joining process

5 · sheet metal connection process

6 · how to join sheet metal

7 · clinching joint sheet metal

IP67 rated enclosures designed for use with control switches and equipment. Available box materials include robust ABS plastic or flame retardant Polycarbonate.

When it comes to assembling sheet metal components, designers and manufacturers have several options to choose from. Each attachment method has its own .Sheet metal joining methods include both temporary and permanent solutions as well as those that require additional parts and pre-work. These methods include, mechanical fastening, welding, rivets, brazing and soldering, tongue and .

Folding and adding bending tabs is one of the easiest and most economical way of making moderately strong joints in sheet-metal parts that will permanently or semi-permanently attach to. You will assemble sheet metal by inserting a tongue into a groove. The tongue is designed at the end of the metal and is inserted at the groove of another metal. Sheet metal assembly for these elements will be achieved .Nearly every sheet metal assembly contains sheet metal joints. From ducts to frames to skins, these sheet metal joints are extremely common but generally unknown to the common viewer. Sheet metal fabrication techniques create .

A robust solution for any type of sheet metal, self-clinching fasteners can provide stable threads or attachment in metal as thin as 0.20 mm/.008”. Self-clinching is an innovative fastening method that provides environmental benefits and .The attachment points of concealed fastener panels are hidden, adding to the sleek, clean look of these panels . This combined beauty and durabil - ity can easily be specified by the designer to meet a project’s architectural and the structural performance requirements . The structural design methods presented in this guide follow

recommended attachment method for your application. The Engineer of Record shall determine the required fastening type and pattern. This is typically noted on the . specifically designed for deck attachment, through the sheet metal decking and into the base steel. A powder cartridge (blank cartridge) is used as the energy source to drive the

Study with Quizlet and memorize flashcards containing terms like Why are pure metals a poor choice for sheet metal ducts?, The metal that makes stainless steel resistant to stains is, Grooved seams are rarely used in metals thicker than and more. Here are 4 methods used for attaching metal and wood. These can be used for various purposes like metal roofing, railing, decking, cabinet repairing and making art. How To Attach Wood To Metal With Screws. . Remember, attaching wood to thin metal, like sheet metal, needs backup plate to prevent metal from deforming when the rivet is set. . Diamond<>Furr Benefits: Completely Tested: Performed at an accredited IAS test lab. Complete System: Diamond Furr is the only complete trim system. Designed for jobs requiring continuous rigid insulation for 7/8″ cement plaster.; Zero Penetrations: Diamond Furr also eliminates 100% of the fastener penetration through the final WRB around windows, .

How can we ensure secure and durable connections in sheet metal fabrication? This article explores various joining and fastening techniques, including TOX riveting, welding, and nail riveting. You'll discover the pros and cons of each method, practical applications, and how they contribute to the strength and integrity of metal structures. Dive in to understand .

Sherex offers a variety of products for thin sheet metal, plastic, and composite attachments. Our engineering and R&D teams understand manufacturing processes and material and performance requirements, and have created a product portfolio that addresses a .A sheet metal attachment system and method for the installation of underground mine brattices of the type in which a gas impervious barrier of malleable sheet metal is retained on a peripheral framework of slotted beams. The fastening system involves pre-mounting a plurality of bolts projecting from one face of the framework as piercing pins so that the sheet metal may be .Upgraded Electric Drill Plate Cutter, 2024 Newest Metal Nibbler Drill Attachment with Adapter, DIY Metal Drill Attachment, Sheet Metal Knife for Cutting Iron, White Sheet, Steel,Copper, Aluminum 3.7 out of 5 stars 222 With lighter packages made of thinner materials, hardware can get in the way. This has created a demand for more durable, rugged, flexible methods of fastening and joining, such as self-clinching fasteners. Thin sheet metal is a popular choice for use in packaging because it is lightweight and takes up less space.

In like manner, a flush lap joint . involves offsetting one edge to slide under the other piece of material, with the face of each piece being on the same plane.. They can be joined in a wide range of methods like spot welding, solid welding, rivets, and soldering. Standing Seam Joint. Another common type of sheet metal joint is the standing seam, which requires the forming of .

In Figure 3, a standard unlocked bayonet connection between a tube and sheet has been modified and is used to lock the two pieces into place. This can be released with a custom tool, also made of sheet metal. Figure 4 showcases a couple of snap-fit connections. The elasticity of the flange itself can be used to form a latch. REXBETI Double Headed Sheet Metal Nibbler, Drill Attachment Metal Cutter with Extra Punch and Die, 1 Cutting Hole Accessory and 1 Step Drill Bit, Perfect for Straight Curve and Circle Cutting (Gold) .99 $ 37. 99. Get it as soon as Monday, Mar 11. In Stock. From a panel deflection viewpoint, the two thinnest acrylic foam tapes (3M VHB Tape G16F and 3M VHB Tape GPH-160GF) and the rigid structural adhesive (3M Scotch-Weld Metal Bonder Acrylic Adhesive DP8407NS) outperformed all the other attachment methods by passing the L/60 criterion up to 80 psf (3.8 kPa), while the other attachment methods only .

Although self-clinching into ductile metal panels is the most common, broaching, flaring, welding, riveting, and reflow soldering (SMT) can also be used for mechanical attachment. The details of the application determine the most .

Sheet metal is the frequently used component geometry in industries, and the joining of sheets is inevitable. There exist numerous conventional processes for joining sheet metals, but the diverse needs of .

Another popular method of attaching wood to metal without screws is using cleat hinging. This method involves using cleats and plates to hinge the wood to the metal, allowing you to attach them together without using screws. . Yes, it is . The most recognizable method of joining two parts together would be with bolt and nut connections. Bolt-nut connections are generally used for detachable mounting of components and sheet metal parts. A nut is retained based on creating sufficient friction within the thread and between the interfaces of the fastener and Sheet Metal.Best method to Attach Decorative Sheet Metal to a wall? metalworking So, I'm going to cover a wall in 16 gauge A36 steel. . The wall will be covered with 17 pieces of sheet metal ranging from about 10" x 40" at the smallest to 36" x 75" at the largest. . They will be oriented horizontally and are attaching to a brick wall which has been .

10.7.3 Trim Attachment... 10-21 . 10.8 Oil Canning (Surface Distortion) . methods must be used. This includes the spacing and quantity used, as well as the type, or style, specified in the installation. . Metal has always been considered a premium roofing material. The extremely All you have to do is to get the saw up to full speed, touch it to the sheet metal until it goes through, and then pass it along the length of the sheet metal. This method is ideal for cutting straight lines, although it will not work well for cutting curves and intricate shapes. 5. Reciprocating Saw When mounting solar PV to metal roofing, essential criteria such as the method/engineering of attachment should be considered to provide permanence for building owners and ease of installation for solar contractors. . Many products simply use one or two sheet metal screws in the top of the roof panels’ ribs. This method puts the fastening .

Drilling holes through a thin sheet of sheet metal, such as that used for a roof’s flashing, does not require a lot of effort and will make attaching the sheet metal easier. Method 2: Use Roofing Nails. Sheet metal can best be attached with roofing nails. These nails are specially designed to go through sheet metal and into wood and provide a . Investing in high-quality gutters and proper installation is crucial for the longevity and durability of a metal building. 10 Methods How to Put Gutters on a Metal Building 1. Measure the Length of the Building . Install these after cutting and attaching your gutter sections together using connectors or end caps as needed. 6. Connect Seams Step 4. Metal Roofing Panels. The next step is to install the metal roofing itself. Metal roofing typically comes in panels, which are installed step-by-step. The methods vary based on the type of roofing (exposed fastener vs. standing seam) and the manufacturer of the panels.

sheet metal welding process

This is an incredibly flexible way of attaching a pair of sheet metal sections to one another because a welder can choose to use a variety of welding methods. Sometimes, a spot weld is all that is needed for a certain type of fabrication. Where a watertight or even an airtight seal is needed, then a more extensive weld can be conducted along .

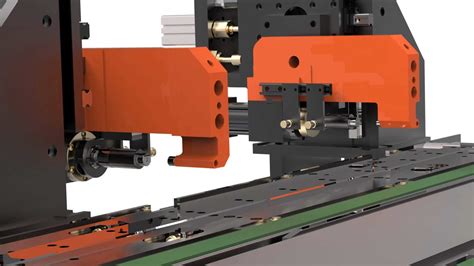

The clinching process is a method of assembling sheet metal without welding or fasteners. With this joining technique, metal parts are deformed locally without the use of any consumables. It creates an interlocking of two or more metal layers. Painted or coated metal sheets can also be joined by this method without damaging the surface.

junction box too deep

junction box vehicle

$14.19

sheet metal attachment method|sheet metal joining techniques