seaming operation in sheet metal • Drozda, Tom; Wick, Charles; Bakerjian, Ramon; Veilleux, Raymond F.; Petro, Louis (10 December 1984), Tool and manufacturing . See more $35.49

0 · what is sheet metal hemming

1 · welding sheet metal seams

2 · sheet metal side seam

3 · sheet metal seam joints

4 · sheet metal seam

5 · sheet metal hemming machine

6 · sheet metal flange seam

7 · sheet metal bending process

SMART is a dynamic and diverse union with 203,000 members in various industries, including sheet metal, air, rail and transportation. Learn about SMART.

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials. Hems are commonly used to reinforce an edge, hide burrs and rough . See moreThe process for both hemming and seaming are the same, except that the tonnage (amount of force exerted) requirement is greater for seaming. The process starts by . See more• Can seamer• Automotive hemming See more• Drozda, Tom; Wick, Charles; Bakerjian, Ramon; Veilleux, Raymond F.; Petro, Louis (10 December 1984), Tool and manufacturing . See more

A seam is used to connect two metal parts by interlocking the edges of the folded sheet metal parts. The resulting shape may even form a seal that isolates one side of the sheets from the other. As a result, seaming finds .

Several types of seams used to join sheet-metal sections are discussed in this section. There are three types of lap seams: the PLAIN LAP seam, the OFFSET LAP seam, and the CORNER . The difference between them is that hemming involves folding sheet metal so that the two layers are flush with each, whereas seaming .

custom part manufacturers

Hemming and seaming are two similar metalworking processes, where a sheet of metal edge is rolled over and over onto itself until it achieves a tight fit. In hemming, the edge is rolled to itself, while in seaming the edges of .

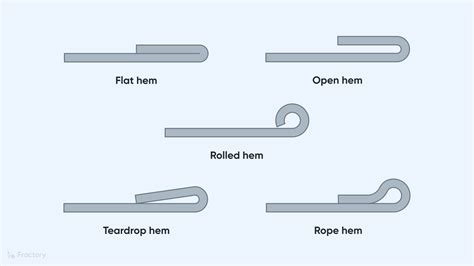

How Does Hem And Seam In Sheet Metal Compare? Metalworking procedures are known as hemming and seaming call for the folding and bending of sheet metal over and into itself. In contrast to seaming, which involves folding sheet . Sheet metal hemming is a type of sheet metal fabrication in which the thin sheet is bent and folded onto itself. The bent can have a closed shape, completely touching the metal surface, or be open with a slight cavity in . In sheet metal fabrication, the hemming process involves bending the same part’s sharp edges to form a reinforcement channel. This process is widely used across the automotive and electronics industries. It cuts thin sheet .

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials.

A stamping process that produces a shallow relief design on sheet metal. Embossing is the operation of forming impressions of figures, letters, or designs on sheet metal. The punch or the die or both of them may have the .Sheet Metal Hemming vs Seaming. As we mentioned above, sheet metal hemming is a process of folding the edge of a single metal sheet back onto itself to create a clean, finished edge. This is typically done by bending the metal over a die or roller, resulting in a 180-degree fold or a tighter, more acute angle.Another type of sheet metal joint is the grooved seam. As seen in the illustration, this joint is a curious combination of a flush lap and open hems. . joining, bending, and forming operations. For more information about sheet metal . 【Easy Operation】 This plier is easy to operate, whether you are a professional or a novice, you can complete the work quickly and efficiently. It has 2 styles optional, mini straight plier and mini 45° bend plier. . Sheet Metal Seamer Form Edge Seamer Seaming Plier with Ergonomic Handle for Bending and Flattening Sheet Metal Hand Tool (A .

SHEET METAL OPERATIONS. SHEET METALWORKING Cutting and forming thin sheets of metal usually performed as cold working Sheet metal = 0.4 (1/64) to 6 mm (1/4in) . Other Bending Operations Flanging Hemming Seaming Curling Channel, U-bending Air bending, Offset bending, Corrugating and Tube forming. BENDING OPERATION . However, the operation cycle time is relatively longer, and the metal sheet orientation can be changed to decrease the travel of the hemming roller. . Sheet Metal Hem Vs Seam. Hemming is a process in which a metal edge is curved to make it smooth and strong. It is applied to strengthen seams, protect sharp edges, and enhance the look of garments.

To successfully perform the sheet hemming operation, ensure the metal sheet is flat without any contaminant that can hinder the process. Then, set up the hemming tool per the preferred hem width and angle. . How is sheet metal hemming different from seaming? Although these methods involve rolling sheet metal edges onto themselves, they differ .【Easy Operation】 This plier is easy to operate, whether you are a professional or a novice, you can complete the work quickly and efficiently. It has 2 styles optional, mini straight plier and mini 45° bend plier. . Sheet Metal Seamer Form Edge Seamer Seaming Plier with Ergonomic Handle for Bending and Flattening Sheet Metal Hand Tool (B . Hemming also allows to join multiple metal sheets which is important for different industrial operations like electronics and construction. . Sheet Metal Heming vs Sheet Metal Seaming. Sheet metal hemming and seaming are both important metal fabrication techniques. Both techniques have different purposes and characteristics. EASY OPERATION: Double-dipped grip for superior comfort bending, stitching or flattening metal sheets. GOOD HAND TOOL: Comfortable handle for long time work without fatigue. . HURRICANE Sheet Metal Hand Seamer, 6 Inch Straight Jaw Sheet Bender Tools for Flattening Metal, Bending Pliers with Double Dipped Cushion Handle.

Normally hemming operations are used to connect parts together, to improve the appearance of a part and to reinforce part edges. In car part production, hemming is used in assembly as a secondary operation after deep drawing, trimming and flanging operations to join two sheet metal parts (outer and inner) together.is a metal forming process in which a force is applied to a piece of sheet metal, causing it to bend at an angle and form the desired shape. . what are seams commonly used for? . is a metal forming process in which sheet metal is progressively shaped through a series of bending operations. About us. About Quizlet; How Quizlet works; Careers . With seaming, the edge of sheet metal is folded but it doesn’t sit flush. Rather, the two layers of the folded sheet metal are joined using a seam. You’ll often find seams on metal roofs. The edges of metal roofs are folded and then joined using a seam. Other applications for seaming involve canned foods, automotive components and storage .

custom perforated metal sheet

The single lock can be converted with optional rolls. The K9 seams 30 fpm, weighs only 40 lbs. and is capable of moving forward and reverse on the roof. “Schlebach Piccolo” power seamer is the most versatile seamer in roofing. Seams 1” or 1 ½” A1301/1300 standing seam panels to 90 or 180 degrees locks, working with flat or curved panels.

Sheet metal joints are connections or seams formed by joining two or more sheets of metal to create a unified structure or component. From riveting and welding to folding and soldering, sheet metal joints offer an array of .

Hemming and seaming are two similar metalworking processes in which a sheet metal edge is rolled over onto itself. Hemming is the process in which the edge is rolled flush to itself, while a seam joins the edges of two materials. 1. .Cut away illustration of a double seam. A double seam is a canning process for sealing a tin can by mechanically interlocking the can body and a can end (or lid).. Originally, the can end was soldered or welded onto the can body after the can was filled. [1] However, this introduced a variety of issues, such as foreign contaminants (including lead and other harmful heavy metals). Column 1: S = Sheet metal thickness; Column 2: A = flattening height; Column 3: Necessary force per metre to flatten sheet metal with 450N/mm 2 tensile strength (mild steel), 1 T = 9.8 KN; Column 4: flatten sheet metal with 700N/mm 2 tensile strength (stainless steel); There are four primary hemming bending solutions designed to accommodate various bending .

custom parts machine shop

Like ductile metals, the ductile materials are rolled or hammered into a thin sheet in some special cases. This property of the material is known as Malleability.So, malleability is the property of the material that gives an identity of sheet metal. the sheet metal or malleable material should be plastic but it is not compulsory to be so strong.Study with Quizlet and memorize flashcards containing terms like Identify the three basic types of sheet metalworking operations., In conventional sheet metalworking operations, (a) what is the name of the tooling and (b) what is the name of the machine tool used in the operations?, In blanking of a circular sheet-metal part, is the clearance applied to the punch diameter or the .Understanding the steps in the sheet metal stamping process demonstrates how high-quality components are produced, guiding businesses toward informed decisions and efficient operations. This comprehensive guide serves as your roadmap to navigating and leveraging this complex process effectively.

Curling sheet metal is the process of adding a hollow, circular roll to the edge of the sheet. The curled edge provides strength to the edge and makes it safe for handling. Curling is different than a tear drop hem because in a curl the edge finishes inside itself, where a .

Hi Friends,In this video you will learn Types of Drawing operations in sheet metal | Common Defects in drawing operationRedrawingReverse redrawingDefects in . Hi Friends,In this video you will learn 18 types of bending operations in sheet metal | Sheet metal bending operationsEdge BendingV-bendingU-BendingChannel B. All beverage cans without seams (known as two-piece cans) are ironed, generally in three steps, after being deep drawn into a cup. . Press for Sheet Metal Press selection for sheet metal forming operations depends on several factors: Type of forming operation, and dies and tooling required Size and shape of work pieces Length of stroke of the . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

Double Seams & Critical Performance Parameters Metal Packaging Solutions - Visual external examination - External measurements - Seam sections - Teardown examination - A visual check should be carried out every hour - A full 1st operation seam evaluation should be carried out once a week - A full 2nd operation seam evaluation should be carried .

what is sheet metal hemming

$36.98

seaming operation in sheet metal|sheet metal seam