metallization process in ic fabrication ppt The most popular method for PVD metallization process, because it can achieve high deposition rate, good film uniformity, high film quality, and easy process control. High deposition rate .

Enjoy your dart games in whole new ways and keep it safe with the Viper Hideaway dartboard cabinet for steel tip darts. This cabinet will complete the look of any game room with a classic .

0 · mosfet fabrication steps

1 · ic fabrication steps

$750.00

This document provides an overview of metallization for integrated circuits. It discusses the requirements and purposes of metallization, including interconnecting .The document provides an overview of integrated circuit fabrication processes. .

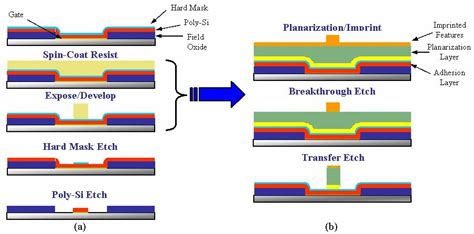

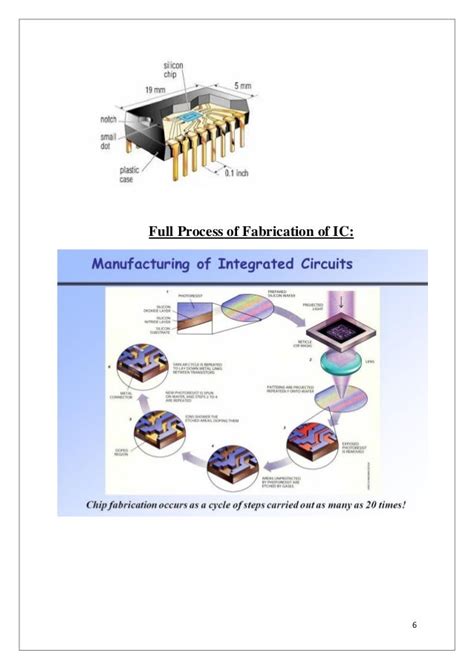

The IC fabrication process involves numerous steps: 1) Silicon wafers are .

diversified metal fabricators dmf

This document discusses metallization in semiconductor device fabrication. Metallization involves depositing a thin metal layer to make interconnections between components on a chip and connections to the . The document provides an overview of integrated circuit fabrication processes. It discusses the basic steps including wafer production, epitaxial growth, etching, masking, doping, diffusion, implantation, and .The most popular method for PVD metallization process, because it can achieve high deposition rate, good film uniformity, high film quality, and easy process control. High deposition rate . Objectives • Explain device application of metallization • List three most commonly used metals • List three different metallization methods • Describe the sputtering process • .

Microelectronic Fabrication Sputtering • The most commonly used PVD process for metallization • Involves energetic ion bombardment, which physically dislodge atoms or molecules from the solid metal surface, and .

mosfet fabrication steps

Metalization Process Ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document discusses metallization in VLSI devices.The PowerPoint PPT presentation: "Chapter 2 Introduction of IC Fabrication" is the property of its rightful owner. Do you have PowerPoint slides to share? If so, share your PPT presentation slides online with PowerShow.com.

The document provides an overview of the integrated circuit fabrication process. It describes the key front-end and back-end processing steps, including wafer fabrication, photolithography, deposition, etching, metallization, dicing, and . The IC fabrication process involves numerous steps: 1) Silicon wafers are manufactured through processes like Czochralski crystal growth and then undergo oxidation, photolithography, etching, diffusion/ion implantation, .

This document provides an overview of metallization for integrated circuits. It discusses the requirements and purposes of metallization, including interconnecting thousands of devices on chips. Two common metallization methods described are vacuum evaporation and sputter deposition.

This document discusses metallization in semiconductor device fabrication. Metallization involves depositing a thin metal layer to make interconnections between components on a chip and connections to the outside world. Common applications of metallization include gates, contacts, and interconnects. The document provides an overview of integrated circuit fabrication processes. It discusses the basic steps including wafer production, epitaxial growth, etching, masking, doping, diffusion, implantation, and metallization. It also describes the fabrication processes for MOSFETs including NMOS, PMOS and CMOS.

The most popular method for PVD metallization process, because it can achieve high deposition rate, good film uniformity, high film quality, and easy process control. High deposition rate allow single-wafer processing, which has several advantages over batch-processing.

Objectives • Explain device application of metallization • List three most commonly used metals • List three different metallization methods • Describe the sputtering process • Explain the purpose of high vacuum in metal deposition processes Microelectronic Fabrication Sputtering • The most commonly used PVD process for metallization • Involves energetic ion bombardment, which physically dislodge atoms or molecules from the solid metal surface, and redeposit them on the substrate as thin metal film. • Argon is normally used as sputtering atom School of Microelectronic EngineeringMetalization Process Ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document discusses metallization in VLSI devices.

The PowerPoint PPT presentation: "Chapter 2 Introduction of IC Fabrication" is the property of its rightful owner. Do you have PowerPoint slides to share? If so, share your PPT presentation slides online with PowerShow.com.The document provides an overview of the integrated circuit fabrication process. It describes the key front-end and back-end processing steps, including wafer fabrication, photolithography, deposition, etching, metallization, dicing, and packaging.

diy flywheel sheet metal

The IC fabrication process involves numerous steps: 1) Silicon wafers are manufactured through processes like Czochralski crystal growth and then undergo oxidation, photolithography, etching, diffusion/ion implantation, and metallization. This document provides an overview of metallization for integrated circuits. It discusses the requirements and purposes of metallization, including interconnecting thousands of devices on chips. Two common metallization methods described are vacuum evaporation and sputter deposition. This document discusses metallization in semiconductor device fabrication. Metallization involves depositing a thin metal layer to make interconnections between components on a chip and connections to the outside world. Common applications of metallization include gates, contacts, and interconnects. The document provides an overview of integrated circuit fabrication processes. It discusses the basic steps including wafer production, epitaxial growth, etching, masking, doping, diffusion, implantation, and metallization. It also describes the fabrication processes for MOSFETs including NMOS, PMOS and CMOS.

The most popular method for PVD metallization process, because it can achieve high deposition rate, good film uniformity, high film quality, and easy process control. High deposition rate allow single-wafer processing, which has several advantages over batch-processing. Objectives • Explain device application of metallization • List three most commonly used metals • List three different metallization methods • Describe the sputtering process • Explain the purpose of high vacuum in metal deposition processes

ic fabrication steps

Microelectronic Fabrication Sputtering • The most commonly used PVD process for metallization • Involves energetic ion bombardment, which physically dislodge atoms or molecules from the solid metal surface, and redeposit them on the substrate as thin metal film. • Argon is normally used as sputtering atom School of Microelectronic EngineeringMetalization Process Ppt - Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. This document discusses metallization in VLSI devices.The PowerPoint PPT presentation: "Chapter 2 Introduction of IC Fabrication" is the property of its rightful owner. Do you have PowerPoint slides to share? If so, share your PPT presentation slides online with PowerShow.com.The document provides an overview of the integrated circuit fabrication process. It describes the key front-end and back-end processing steps, including wafer fabrication, photolithography, deposition, etching, metallization, dicing, and packaging.

diy cnc plasma cutting machine

$14.99

metallization process in ic fabrication ppt|mosfet fabrication steps