different type of sheet metal forming process Different sheet metal forming processes. The relevant tools and equipment needed to form sheet metal will depend on what you want to make. For example, if you need specially shaped holes, cutting with punches and . Welders can use their metal bending and shaping skills to create a variety of industrial, home and art items that are in demand and that can easily be sold. This list of things to weld and sell are just a few ideas to get you started.

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal forming process pdf

4 · sheet metal forming press dies

5 · sheet metal forming by hand

6 · sheet metal bending process pdf

7 · bulk deformation vs sheet metal forming

Find company research, competitor information, contact details & financial data for A & I FABRICATIONS PTY LTD of WETHERILL PARK, NEW SOUTH WALES. Get the latest business insights from Dun & Bradstreet.

Different sheet metal forming processes. The relevant tools and equipment needed to form sheet metal will depend on what you want to make. For example, if you need specially shaped holes, cutting with punches and .Learn about the different types of metal forming processes such as bending, roll forming, and more. Click here!

In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, . However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing. Shearing is . Metal forming is a process of manufacturing components of desired shapes by deforming the material plastically, by the application of compressive force, bending or shear force, tensile force, or combinations of . The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form .

Based upon the manufactured components and the manufacturing process, various kinds of forming are developed. Different types of sheet metal forming processes and their applications and characteristics are discussed below: Roll forming; In this process the sheet metal is passed through a large numbers of set of rollers continuously. The each .

Different sheet metal forming processes. The relevant tools and equipment needed to form sheet metal will depend on what you want to make. For example, if you need specially shaped holes, cutting with punches and dies would be best. Shearing tools are also useful for cutting off small unwanted slithers in a straight line.

Learn about the different types of metal forming processes such as bending, roll forming, and more. Click here! In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, advancements, applications, and more. However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing. Shearing is similar to what the name suggests—cutting through a sheet of metal in a straight line or curve.

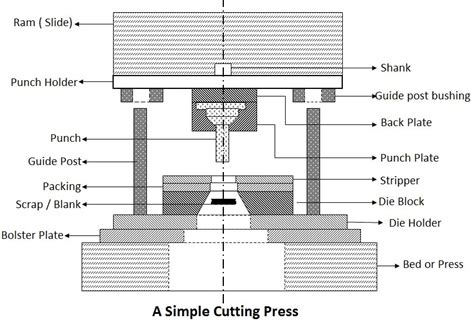

Metal forming is a process of manufacturing components of desired shapes by deforming the material plastically, by the application of compressive force, bending or shear force, tensile force, or combinations of these all forces together, without adding or removing material.Sheet metal forming involves the application of tensile or shear forces predominantly. Working upon sheets, plates and strips mainly constitutes sheet forming. Sheet metal operations are mostly carried out in presses – hydraulic or pneumatic. A set of tools called die and punch are used for the sheet working operations.

Sheet metal is an industrial process that forms thin, flat pieces of metal, such as steel and tin, into coils. In the U.S., the thickness of sheet metal is typically specified by its gauge, which ranges from 30 gauge to about 7 gauge. Other metals like aluminum, brass, copper, steel, tin, nickel, and titanium can also be used in sheet metal.

Metal punching, extrusion, press braking, rolling, forging and laser cutting are some of the more common forming processes. Here are more details on each technique: Common Types of Forming. The most common metal . The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form .

Based upon the manufactured components and the manufacturing process, various kinds of forming are developed. Different types of sheet metal forming processes and their applications and characteristics are discussed below: Roll forming; In this process the sheet metal is passed through a large numbers of set of rollers continuously. The each . Different sheet metal forming processes. The relevant tools and equipment needed to form sheet metal will depend on what you want to make. For example, if you need specially shaped holes, cutting with punches and dies would be best. Shearing tools are also useful for cutting off small unwanted slithers in a straight line.

Learn about the different types of metal forming processes such as bending, roll forming, and more. Click here! In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, advancements, applications, and more.

sheet metal working process pdf

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing. Shearing is similar to what the name suggests—cutting through a sheet of metal in a straight line or curve. Metal forming is a process of manufacturing components of desired shapes by deforming the material plastically, by the application of compressive force, bending or shear force, tensile force, or combinations of these all forces together, without adding or removing material.Sheet metal forming involves the application of tensile or shear forces predominantly. Working upon sheets, plates and strips mainly constitutes sheet forming. Sheet metal operations are mostly carried out in presses – hydraulic or pneumatic. A set of tools called die and punch are used for the sheet working operations.Sheet metal is an industrial process that forms thin, flat pieces of metal, such as steel and tin, into coils. In the U.S., the thickness of sheet metal is typically specified by its gauge, which ranges from 30 gauge to about 7 gauge. Other metals like aluminum, brass, copper, steel, tin, nickel, and titanium can also be used in sheet metal.

cnc machined aluminum component suppliers

cnc machine wood near me

Electrical boxes, also known as junction boxes, are an essential component of any electrical system. They serve as a protective enclosure for electrical connections and devices, helping to prevent electrical fires and other hazards.

different type of sheet metal forming process|sheet metal forming process pdf