different types of sheet metal operations However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing. Shearing is . We offer flexibility in style, options, and accessories with our two story metal building kits. Take your metal building to the next level with Quicken Steel.

0 · types of sheet metal pdf

1 · sheet metal operations pdf

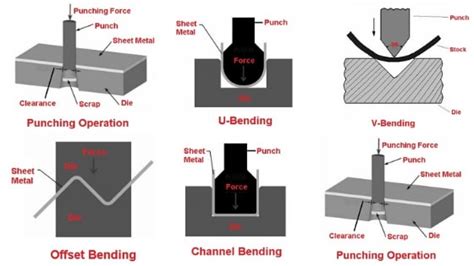

2 · sheet metal bending diagram

3 · shearing operation in sheet metal

4 · notching operation in sheet metal

5 · name various sheet metal operations

6 · embossing operation in sheet metal

7 · drawing operation in sheet metal

Required for all projects using junction boxes, manholes, and inlets beginning with the May 2019 letting. Statewide Use. 2014 English Special Provisions by Item (Statewide & Districtwide, Current)

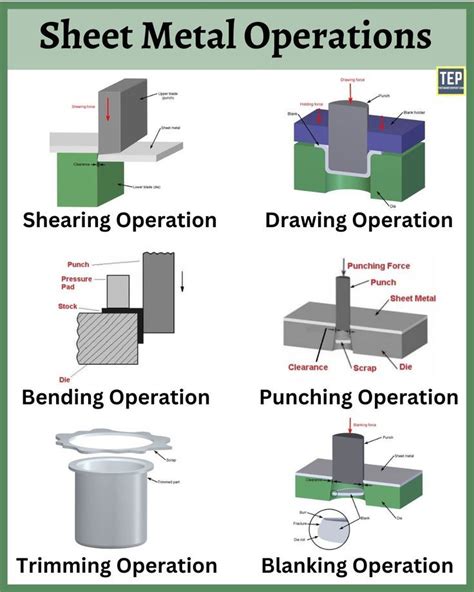

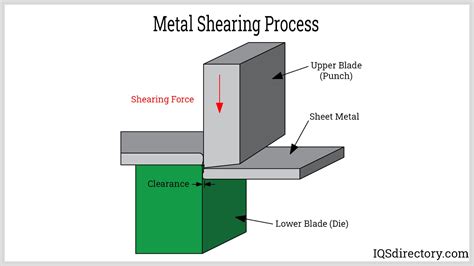

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing. Shearing is .In this article, you’ll learn the various types of sheet metal operations with their diagrams. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing . In this article, we will discuss the various types of Sheet Metal Operations. But before moving ahead to understand these operations, we should also understand what actually the sheet metal is. Sheet Metal: Sheet Metal is . Different Types of Sheet Metal Operations are: Shearing Operation; Blanking & Fine Blanking Operation; Punching Operation; Piercing Operation (poking lots of holes in) Operation Perforating Operation; Slotting Operation; .

Gaining insight into the different types of sheet metal operations and their applications underscores the value of custom metal fabrication. This article delves into these operations, . Discover the wide range of sheet metal operations, from punching to plasma cutting. Get an in-depth understanding to aid your manufacturing decisions.types of forming sheet metal. The basic sheet metal operations are sketched in Figure and are defined as follows: Bending: Bending involves the straining of a metal sheet or plate to take an angle along a (usually) straight axis. Drawing: . Following are the 9 different types of sheet metal operations: It is cut in a straight line across a strip, sheet, or bar. It leaves a lean edge on the piece of metal that is sheared or cut. In this operation, a sheet metal workpiece is placed or kept between two dies from one end.

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing. Shearing is similar to what the name suggests—cutting through a sheet of metal in a straight line or curve. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Learn about sheet metal here! Sheet Metals: Application, Materials, Types, Thickness & ProcessesIn this article, you’ll learn the various types of sheet metal operations with their diagrams. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Shearing Operations. The Shearing operation is a cut in a straight line across a strip, sheet, or bar.

There are various types of sheet metal operations for making products. Some basic operations list is below. Blanking Punching; Piercing ; Cut-off ; Parting off ; Notching ; Bending; Let we will discuss the types of sheet metal operations in detail. What Are the Basic Properties of . In this article, we will discuss the various types of Sheet Metal Operations. But before moving ahead to understand these operations, we should also understand what actually the sheet metal is. Sheet Metal: Sheet Metal is a thin sheet produced by rolling or hammering. Different Types of Sheet Metal Operations are: Shearing Operation; Blanking & Fine Blanking Operation; Punching Operation; Piercing Operation (poking lots of holes in) Operation Perforating Operation; Slotting Operation; Notching Operation; Bending Operation; 1). Sheet Metal Shearing Operations

Gaining insight into the different types of sheet metal operations and their applications underscores the value of custom metal fabrication. This article delves into these operations, highlighting their significance and specific uses in the industry. Discover the wide range of sheet metal operations, from punching to plasma cutting. Get an in-depth understanding to aid your manufacturing decisions.types of forming sheet metal. The basic sheet metal operations are sketched in Figure and are defined as follows: Bending: Bending involves the straining of a metal sheet or plate to take an angle along a (usually) straight axis. Drawing: In sheet metalworking, drawing refers to the forming of a flat metal sheet into a hollow or concave shape . Following are the 9 different types of sheet metal operations: It is cut in a straight line across a strip, sheet, or bar. It leaves a lean edge on the piece of metal that is sheared or cut. In this operation, a sheet metal workpiece is placed or kept between two dies from one end.

types of sheet metal pdf

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing. Shearing is similar to what the name suggests—cutting through a sheet of metal in a straight line or curve. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Learn about sheet metal here! Sheet Metals: Application, Materials, Types, Thickness & ProcessesIn this article, you’ll learn the various types of sheet metal operations with their diagrams. The common types of sheet metal operations are shearing, blanking, punching, piercing, trimming, drawing, embossing, bending, and squeezing operations. Shearing Operations. The Shearing operation is a cut in a straight line across a strip, sheet, or bar.There are various types of sheet metal operations for making products. Some basic operations list is below. Blanking Punching; Piercing ; Cut-off ; Parting off ; Notching ; Bending; Let we will discuss the types of sheet metal operations in detail. What Are the Basic Properties of .

In this article, we will discuss the various types of Sheet Metal Operations. But before moving ahead to understand these operations, we should also understand what actually the sheet metal is. Sheet Metal: Sheet Metal is a thin sheet produced by rolling or hammering.

Different Types of Sheet Metal Operations are: Shearing Operation; Blanking & Fine Blanking Operation; Punching Operation; Piercing Operation (poking lots of holes in) Operation Perforating Operation; Slotting Operation; Notching Operation; Bending Operation; 1). Sheet Metal Shearing Operations

Gaining insight into the different types of sheet metal operations and their applications underscores the value of custom metal fabrication. This article delves into these operations, highlighting their significance and specific uses in the industry. Discover the wide range of sheet metal operations, from punching to plasma cutting. Get an in-depth understanding to aid your manufacturing decisions.

sheet metal gutter profiles

sheet metal operations pdf

Adding a Model 2100A wall plate and a 12-volt IR target to the coax run of any room allows IR signals to be routed to either a Model 2010 wall plate, 5500 series, or SVM series modulator. Features 54 MHz to 1 GHz forward bandwidth

different types of sheet metal operations|sheet metal bending diagram