difference between cnc and additive manufacturing Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is . The best welders for sheet metal is a MIG or TIG welder due to their precision and control. Key specifications include a wide amperage range for better control, a high duty cycle for longer welding sessions, and a stable arc for clean, high-quality welds.

0 · difference between cnc and am

1 · cnc vs additive manufacturing

2 · cnc machining vs am

Typically, you should use warm metals (like brass, nickel and copper) with warm hues (like whites, beiges, browns and taupes) and cool metals (such as chrome and silver) with cool hues (such as blues, greens and grays). .

difference between cnc and am

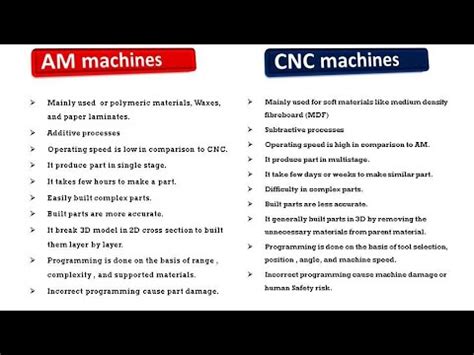

The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while . Additive manufacturing and CNC (Computer Numerical Control) are different processes. CNC involves removing material from a solid block using various tools, while .Two of the most dominant manufacturing technologies in the industry today are Additive Manufacturing (AM) and CNC (Computer Numerical Control) Machining. While both have their .Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is .

Unlike additive manufacturing, CNC machining is a subtractive manufacturing method that starts with a block of raw material and removes it bit by bit using rotating tools until it achieves the desired shape.Additive Manufacturing (AM) and CNC Machining can be combined together. Additive Manufactured parts can respond under stress differently than on-the-shelf materials due to the inner structure. With Additive Manufacturing (AM) .Additive manufacturing and CNC manufacturing are two popular production techniques that produce precise and functional metal parts fast and efficiently. Both are powerful and sophisticated manufacturing resources that bring any .

Additive manufacturing allows for complex geometries and customization, while CNC machining offers high precision and speed. The choice between these techniques depends on factors . Boeing and other manufacturers use three primary criteria to measure the value of additive manufacturing (AM) against CNC Machining: part performance, cost and lead time . The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.Additive manufacturing and CNC (Computer Numerical Control) are different processes. CNC involves removing material from a solid block using various tools, while additive manufacturing, or 3D printing, builds objects layer by layer from digital models.

Two of the most dominant manufacturing technologies in the industry today are Additive Manufacturing (AM) and CNC (Computer Numerical Control) Machining. While both have their unique advantages, they serve diverse purposes and function with distinct mechanisms.Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes. CNC machining and additive manufacturing are two distinct manufacturing techniques that are widely used in the production of parts and components. CNC machining involves the use of computer-controlled machines to remove material from raw materials, such as metal or plastic, to create a final product.

Unlike additive manufacturing, CNC machining is a subtractive manufacturing method that starts with a block of raw material and removes it bit by bit using rotating tools until it achieves the desired shape.Additive Manufacturing (AM) and CNC Machining can be combined together. Additive Manufactured parts can respond under stress differently than on-the-shelf materials due to the inner structure. With Additive Manufacturing (AM) material shaping process can be long.

Additive manufacturing and CNC manufacturing are two popular production techniques that produce precise and functional metal parts fast and efficiently. Both are powerful and sophisticated manufacturing resources that bring any design concept to life.

Additive manufacturing allows for complex geometries and customization, while CNC machining offers high precision and speed. The choice between these techniques depends on factors such as the desired part characteristics, volume of production, lead time, and cost considerations.

Boeing and other manufacturers use three primary criteria to measure the value of additive manufacturing (AM) against CNC Machining: part performance, cost and lead time (see our blog post on this). In the past, metal AM processes were expensive and slow.

The difference between additive manufacturing and CNC machining comes down to their core approaches: additive manufacturing builds parts layer by layer, offering design freedom and efficient prototyping, while CNC machining subtracts material to achieve high precision, repeatability, and smooth finishes in production.Additive manufacturing and CNC (Computer Numerical Control) are different processes. CNC involves removing material from a solid block using various tools, while additive manufacturing, or 3D printing, builds objects layer by layer from digital models.Two of the most dominant manufacturing technologies in the industry today are Additive Manufacturing (AM) and CNC (Computer Numerical Control) Machining. While both have their unique advantages, they serve diverse purposes and function with distinct mechanisms.Additive Manufacturing (AM) and CNC (Computer Numerical Control) manufacturing are two dominant prototyping methods. Understanding the differences between these methods is crucial for businesses and designers looking to improve their new product development processes.

CNC machining and additive manufacturing are two distinct manufacturing techniques that are widely used in the production of parts and components. CNC machining involves the use of computer-controlled machines to remove material from raw materials, such as metal or plastic, to create a final product.

cnc vs additive manufacturing

Unlike additive manufacturing, CNC machining is a subtractive manufacturing method that starts with a block of raw material and removes it bit by bit using rotating tools until it achieves the desired shape.Additive Manufacturing (AM) and CNC Machining can be combined together. Additive Manufactured parts can respond under stress differently than on-the-shelf materials due to the inner structure. With Additive Manufacturing (AM) material shaping process can be long.

Additive manufacturing and CNC manufacturing are two popular production techniques that produce precise and functional metal parts fast and efficiently. Both are powerful and sophisticated manufacturing resources that bring any design concept to life.Additive manufacturing allows for complex geometries and customization, while CNC machining offers high precision and speed. The choice between these techniques depends on factors such as the desired part characteristics, volume of production, lead time, and cost considerations.

how to fix a protruding electrical box

The basic cost to Remodel an Electrical Box is $1,271 - $1,541 per box in September 2024, but can vary significantly with site conditions and options. Use our free HOMEWYSE CALCULATOR to estimate fair costs for your SPECIFIC .

difference between cnc and additive manufacturing|cnc vs additive manufacturing