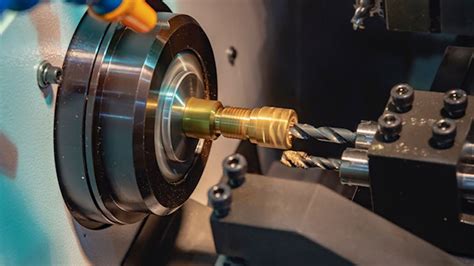

cnc brass machined part We offer a complete CNC machining service for brass parts and can produce complex Brass parts in Brass C360. Brass parts are great for applications that require high strength, corrosion resistance, a low friction coefficient, electrical conductivity and overall versatility.

There are four main types of tools required for processing sheet metals. These tools are as explained below: As the name suggests, sheet metal bending is a process in which the metal is bent by keeping its volume .

0 · machinability of brass

1 · is brass easy to cut

2 · copper and brass machine shops

3 · cnc machine for brass parts

4 · cnc machine for brass

5 · cnc brass parts

6 · brass machinability chart

7 · brass against the machine coplot

When it comes to selecting the ideal metal star for your home, consider the color, material, and type of paint or finish that best suits your design preferences and the overall character of your property.

Machinists commonly refer to this alloy as free machining brass. It is the most common brass grade used in machining. It is renowned for its high machinability and tensile strength. Its high machinability is attributed to its lead content which makes up about 3% of its constituents. Machinists use it for machining . See more

Machinists refer to this grade as the red brass or Nordic brass. It also has moderate strength and good anti-rust properties. The C230 is popular for its season-breaking and . See more

Machinists refer to this alloy as commercial bronze. Despite the name, its constituent still makes it a brass alloy due to its higher copper content. It has a good machinability rating, . See more

We offer a complete CNC machining service for brass parts and can produce complex Brass parts in Brass C360. Brass parts are great for applications that require high strength, corrosion resistance, a low friction coefficient, electrical .

In this CNC machining brass guide, we’ll examine the properties of brass and the various brass grades used for custom brass parts. We’ll also review the applications of brass manufacturing and the factors to consider when picking brass for a machining project.

We offer a complete CNC machining service for brass parts and can produce complex Brass parts in Brass C360. Brass parts are great for applications that require high strength, corrosion resistance, a low friction coefficient, electrical conductivity and overall versatility. cnc turning machined brass parts. Milling: Brass is placed on a milling machine, where the tools are responsible for cutting and shaping, with various tool shapes and sizes achieving complex machining requirements.Well rounded properties make brass a versatile metal for CNC machined components. What is Brass? Brass is an alloying consisting of both copper and zinc. The gold material is a weather- and corrosion- resistant metal with tensile strength similar to mild steel.Discover the benefits of precision brass CNC machining for custom brass parts. Get insights on brass types, applications, and more. Order your brass parts with confidence.

Specialized in custom-made quality Brass turning parts and machined parts. Precision machining components according to customers' specifications & industry standards.Our brass machined parts are meticulously engineered with custom machined components derived from 2D/3D drawings, making them ideal for a wide range of industrial applications. When you require top-notch brass machined parts, Rally's brass .We work with both free machining and Naval brass and offer numerous plating options, including electroless nickel plating, which adds a less porous, all-enveloping barrier to CNC brass parts for superior corrosion resistance.

CNC machining brass produces quality brass components with extreme precision and aesthetic surface finish. It facilitates the production of parts like light fixtures, pipes, fittings, flare fitting, gears, etc. Brass CNC turning involves the use of a lathe to create cylindrical parts by cutting away brass material from a workpiece. Brass and its alloys are relatively easy to machine, have good corrosion resistance, and are aesthetically pleasing. In this CNC machining brass guide, we’ll examine the properties of brass and the various brass grades used for custom brass parts. We’ll also review the applications of brass manufacturing and the factors to consider when picking brass for a machining project.We offer a complete CNC machining service for brass parts and can produce complex Brass parts in Brass C360. Brass parts are great for applications that require high strength, corrosion resistance, a low friction coefficient, electrical conductivity and overall versatility.

cnc turning machined brass parts. Milling: Brass is placed on a milling machine, where the tools are responsible for cutting and shaping, with various tool shapes and sizes achieving complex machining requirements.

the vallley of steel boxes

Well rounded properties make brass a versatile metal for CNC machined components. What is Brass? Brass is an alloying consisting of both copper and zinc. The gold material is a weather- and corrosion- resistant metal with tensile strength similar to mild steel.

Discover the benefits of precision brass CNC machining for custom brass parts. Get insights on brass types, applications, and more. Order your brass parts with confidence.Specialized in custom-made quality Brass turning parts and machined parts. Precision machining components according to customers' specifications & industry standards.

machinability of brass

Our brass machined parts are meticulously engineered with custom machined components derived from 2D/3D drawings, making them ideal for a wide range of industrial applications. When you require top-notch brass machined parts, Rally's brass .We work with both free machining and Naval brass and offer numerous plating options, including electroless nickel plating, which adds a less porous, all-enveloping barrier to CNC brass parts for superior corrosion resistance. CNC machining brass produces quality brass components with extreme precision and aesthetic surface finish. It facilitates the production of parts like light fixtures, pipes, fittings, flare fitting, gears, etc.

is brass easy to cut

copper and brass machine shops

Metal fabrication is a manufacturing process used to shape metal into parts or end products. It usually consist of three phases: 1) design, where shop drawings are created to the intended measurements; 2) fabrication, which involves cutting, bending, and/or assembling; and, 3) installation, where the end product or structure is put together .

cnc brass machined part|copper and brass machine shops