cnc machine proper velocity Here is the chart with the recommended cutting speed for different materials. 1. Materials: cutting speed for aluminum, brass, bronze, cast iron, magnesium, copper, stainless steel, carbon steel, titanium, etc. 2. Machining . One of the most significant advantages of using CNC duct fabrication machines is the increased efficiency and productivity they offer. CNC machines are able to work faster and more accurately than manual machines, resulting in increased output and reduced labor costs.

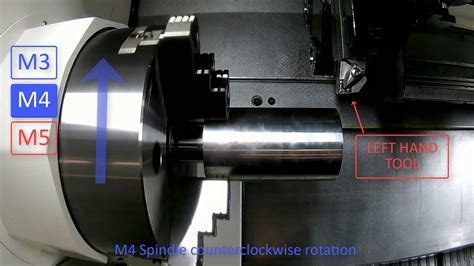

0 · rotation move cnc

1 · machining cutting speed chart

2 · inverse time cnc machining

3 · cutting speed in machining

4 · cnc speeds and feeds chart

5 · cnc machining speeds and feeds

6 · cnc machining problems

7 · cnc cutting speed chart

A residential transformer box, often referred to simply as a “transformer box,” is a component of the electrical distribution system. It is a small, typically green, metal box located on the ground in residential neighborhoods.

Discover the critical distinctions between feed rate and cutting speed in CNC machining. Learn how adjusting these factors impacts material removal, surface finish, and tool lifespan, and explore strategies to balance them for optimal precision, productivity, and durability. Every CNC machining operation requires you to set the optimal speeds and feeds for the process. They are two of the most important parameters in machining that directly affect quality, efficiency, and tool life. Inverse Time Feed is really just "time feed," where the CAM figures out exactly how many seconds the cut should take for all axes, and the control just moves them at the proper .

Here is the chart with the recommended cutting speed for different materials. 1. Materials: cutting speed for aluminum, brass, bronze, cast iron, magnesium, copper, stainless steel, carbon steel, titanium, etc. 2. Machining . Feed rate and cutting speed help optimize different aspects of the CNC machining process. While the cutting speed optimizes the power consumption and cutting tool’s life, the feed rate controls the surface . Cutting speed and feed rate optimization are crucial for any CNC machining operation. By understanding and adjusting these parameters, machinists can improve tool longevity, productivity, surface finish, and the .Feeds and speeds are important parameters in CNC machining that directly affect the product quality, accuracy, and surface finish, as well as machining efficiency and tool life. But what factors affect these parameters, and how do you .

Setting CNC machine parameters is crucial for ensuring the machine operates correctly and produces high-quality products. By understanding the types of CNC machine . Because of this, basic lathes give you less speed options. On the other hand, CNC machines have adjustable speeds between 20 to 200 m/min which depends on what you’re .Discover the critical distinctions between feed rate and cutting speed in CNC machining. Learn how adjusting these factors impacts material removal, surface finish, and tool lifespan, and explore strategies to balance them for optimal precision, productivity, and durability. Every CNC machining operation requires you to set the optimal speeds and feeds for the process. They are two of the most important parameters in machining that directly affect quality, efficiency, and tool life.

Inverse Time Feed is really just "time feed," where the CAM figures out exactly how many seconds the cut should take for all axes, and the control just moves them at the proper velocity so they all reach the block end point at the same time. Here is the chart with the recommended cutting speed for different materials. 1. Materials: cutting speed for aluminum, brass, bronze, cast iron, magnesium, copper, stainless steel, carbon steel, titanium, etc. 2. Machining process: cutting speed for turning, drilling, reaming, and end milling. 3.

CNC machining is the backbone of many manufacturers’ processes. Feeds and speeds refer to two separate velocities for machine tools: feed rate and cutting speed. Learn more about understanding feeds and speeds in CNC machining and how they can be optimized for improved processes and productivity. Feed rate and cutting speed help optimize different aspects of the CNC machining process. While the cutting speed optimizes the power consumption and cutting tool’s life, the feed rate controls the surface roughness of the finished products and the machining time. Cutting speed and feed rate optimization are crucial for any CNC machining operation. By understanding and adjusting these parameters, machinists can improve tool longevity, productivity, surface finish, and the overall CNC machining outcome.

Feeds and speeds are important parameters in CNC machining that directly affect the product quality, accuracy, and surface finish, as well as machining efficiency and tool life. But what factors affect these parameters, and how do you determine the optimum speed and feed for your machining process? Setting CNC machine parameters is crucial for ensuring the machine operates correctly and produces high-quality products. By understanding the types of CNC machine parameters, the factors influencing parameter settings, the steps for setting them, the recommended parameters for different materials, and the methods for optimizing parameter . Because of this, basic lathes give you less speed options. On the other hand, CNC machines have adjustable speeds between 20 to 200 m/min which depends on what you’re making. . These changes help to control heat and proper chip formation. Feed Rate and Cutting Velocity Interaction. There are two main movements in the cutting process .

Discover the critical distinctions between feed rate and cutting speed in CNC machining. Learn how adjusting these factors impacts material removal, surface finish, and tool lifespan, and explore strategies to balance them for optimal precision, productivity, and durability.

Every CNC machining operation requires you to set the optimal speeds and feeds for the process. They are two of the most important parameters in machining that directly affect quality, efficiency, and tool life. Inverse Time Feed is really just "time feed," where the CAM figures out exactly how many seconds the cut should take for all axes, and the control just moves them at the proper velocity so they all reach the block end point at the same time.

Here is the chart with the recommended cutting speed for different materials. 1. Materials: cutting speed for aluminum, brass, bronze, cast iron, magnesium, copper, stainless steel, carbon steel, titanium, etc. 2. Machining process: cutting speed for turning, drilling, reaming, and end milling. 3.

CNC machining is the backbone of many manufacturers’ processes. Feeds and speeds refer to two separate velocities for machine tools: feed rate and cutting speed. Learn more about understanding feeds and speeds in CNC machining and how they can be optimized for improved processes and productivity. Feed rate and cutting speed help optimize different aspects of the CNC machining process. While the cutting speed optimizes the power consumption and cutting tool’s life, the feed rate controls the surface roughness of the finished products and the machining time. Cutting speed and feed rate optimization are crucial for any CNC machining operation. By understanding and adjusting these parameters, machinists can improve tool longevity, productivity, surface finish, and the overall CNC machining outcome.

front house metal door

Feeds and speeds are important parameters in CNC machining that directly affect the product quality, accuracy, and surface finish, as well as machining efficiency and tool life. But what factors affect these parameters, and how do you determine the optimum speed and feed for your machining process? Setting CNC machine parameters is crucial for ensuring the machine operates correctly and produces high-quality products. By understanding the types of CNC machine parameters, the factors influencing parameter settings, the steps for setting them, the recommended parameters for different materials, and the methods for optimizing parameter .

rotation move cnc

machining cutting speed chart

Sheet metal has its roles to play in the household, semi-commercial, commercial and industrial sectors. And whoever working with these sheets, have to deal with mixed types of them. So, what are these types? How do they differ from themselves? And what are the uses?

cnc machine proper velocity|inverse time cnc machining