when to use metal junktion box Knowing when to use each type can save you time, money, and potential headaches. This guide will discuss the pros and cons of plastic and metal junction boxes, . You can also rely on water and oil-displacing lubricants when looking to remove tape residue. WD-40will serve you well, especially if you spray a generous amount on the metallic surface. Ensure you put on a safety glove before spraying the WD40 lubricant . See more

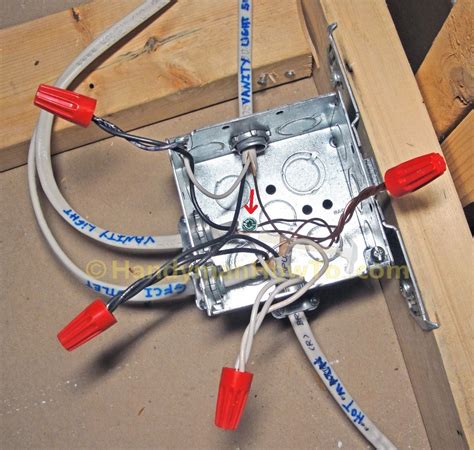

0 · wiring a metal junction box

1 · when to use metal junction box

2 · when to use a metal box

3 · plastic or metal junction box

4 · metal junction boxes

5 · metal junction box replacement

6 · electrical junction box installation

7 · electrical junction box

The Raco Saddlebox, the Westinghouse Fanmaster Jr box, the SmartBox ceiling box, and the Arlington MB-8 are four compliant options to install a ceiling box in old work to .

Use a metal electrical box when metal-sheathed cable (also called armored BX cable) or metal conduit runs in or out of the box. Metal cable and conduit depend on the contact from its metal sheathing to the metal box to complete grounding. Metal Junction Box: Metal junction boxes are more long-lasting as they have high melting points ( from 660°C to 1,538°C ) and are stronger than plastic boxes so, they can be used long-term. Plastic Junction Box: Plastic . Knowing when to use each type can save you time, money, and potential headaches. This guide will discuss the pros and cons of plastic and metal junction boxes, .

Metal junction boxes are more durable, they are fire resistant and are used for wet or high-temperature areas. When To Use A Plastic Electric Box? Let’s review situations when you should use a plastic electrical box: When .

You may also use metal for an outdoor junction box. They are not affordable, like plastic junction boxes; however, they are more promising than plastic ones in terms of guaranteed corrosion resistance. A junction box – also known as an ‘electrical box’, ‘jbox’, ‘or ‘terminal box’ – is a protective box where wires are interconnected. Junction boxes are often built into the plaster of a wall, in the ceiling, or within concrete.

If you have a metal box, use a screwdriver as a lever to remove the knockouts (the precut metal discs on either side of the box). You’ll also need to install cable clamps in the metal box. These thread into the box from the outside.

Metal junction boxes are one of the most common types of electrical boxes used in residential and commercial installations. These boxes are typically made of steel or aluminum . Then you can use the junction screw as a grounding screw because its not used for the fixture support. Rare occasions would this be used anyway. . That may happen 1 out of 50 times you use a metal J-box? get some 10/32 screws and use the threaded hole and use the cover screws for that, covers. Yes I am a Pirate, 200 years too late. . There are various types of junction boxes, including metal and plastic variants, each serving specific purposes in different applications. . Overcrowding the junction box, using the wrong type or size of the box, poor .

You can't use a voltmeter to check the box by putting one of your probes to one side of the box and one on the other side. You need to kill all power to the electrical circuits in the box and using you continuity tester to "ring out" which hot wire is going to ground at the box.LeMotech Aluminum Alloy Metal Junction Box IP67 Waterproof Dustproof Small Electrical Box Outdoor Universal Enclosure Grey 2.5x2.2x1.3in (64x58x35mm) 4.7 out of 5 stars. 34. .99 $ 9. 99. 5% off coupon applied Save 5% with coupon. FREE delivery Mon, Sep 16 on of items shipped by Amazon.Metal boxes are compatible with metal clad wires. Metal boxes have better shallow options and can easily be combined to make multigang options not available in plastic. Plastic boxes are cheaper and faster to work with but not so much so that it's worth an extra trip to a supply house. Commercial work there is no choice. We use metal boxes.

In most cases, the junction box manufacturer makes it easy by listing the number of connections that can run through the product. Material Options: Metal vs. Plastic. Junction boxes are available in metal and plastic. Metal boxes are used for metal conduit or armored (BX) cable installations. They provide excellent durability and grounding . The downside is that metal electrical junction boxes are higher cost, heavier, and conductive. Because metal is conductive, you’ll need to ground your metal junction box. Metal junction boxes also have the downside of being susceptible to corrosion – although this depends on the type of metal used. There are three main types of metal . Metal vs. Plastic Junction Boxes When it comes to junction boxes, the debate often boils down to two materials: metal and plastic. Each has its pros and cons, so let’s break it down! Metal Junction Boxes Pros: Durability: Metal boxes .

It is great for replacing existing ceiling junction box since most junction boxes are mounted against joist. This box has a metal bracket behind plastic box which makes it strong. Most other plastic boxes I have seen are designed to use wood screws directly into the joist holding the junction box for hanging ceiling fan. So, should I use a metal or plastic junction box for under the insulation? If I use metal, I can ensure it is grounded via the splice. Thanks, Charlie . Upvote #2 10-25-18, 05:12 PM PJmax. Group Moderator. Join Date: Oct 2012. Location: Jersey. Posts: 67,136 Upvotes: 501 Received 4,386 .

In my area of the world, junction boxes are allowed provided they remain accessable. However, the code is silent on how heavy a wire can be spliced using a junction box. I get a bit nervous when the amperage gets up to 40 and the voltage is 240. In the short term, I am sure that it will work but time and corrosion can take a toll. In certain situations, using a metal junction box is not just a good idea but necessary. For Metallic-Sheathed Wires and High-Stress Installations: Metal boxes are a must if you’re working with metallic-sheathed wires, also known as BX cable. These boxes provide grounding, which is essential for safety. .POPANU LED-Canless Downlight Recessed Lighting 4-inch 5 CCT Adjustable Dimmable Recessed Lights Fixture with Junction Box, Ceilling Light with Junction Box, 2700-5000K, 9W, White Finish, 6 Pack 4.7 out of 5 stars 140 The potential problem is that if anything goes wrong inside the box and something is loose, the metal cover can become energized. If a metal box or cover is used, it has to be grounded. If there isn't a ground or you don't want to do it, then don't use a metal cover.

I reside in CT - Anyone know if I can run my indoor Romex wire through house wall into a metal junction box? From there I'll run Schedule 40 with THHN wire out to endpoints. Core question here is - Can I run Romex through . This is covered by 314.25(A), which requires metal covers and plates be grounded per 250.110. Unlikely to be energized does not relinquish the requirement. Besides, the only metal cover on a box that is unlikely to be energized is one that is not part of a complete system. just use a metal box that has the side mount bracket on it (like a RACO 235) and mount it so it ends up almost flush with joist bottoms. re run the lines thru the new holes you drill and staple to the sides nearest the entry to the box, then leave some extra and feed into the metal box. make sure to ground metal box when using romex

Find Weatherproof junction boxes at Lowe's today. Shop junction boxes and a variety of electrical products online at Lowes.com. As long as the existing dryer connection is 4-wire, or is 3-wire with insulated neutral and solid metal conduit back to the panel, then it may be extended. . Use a junction box extension, or a surface conduit system like Legrand Wiremold. Share. Improve this answer. Follow edited Oct 13, 2022 at 0:36. answered Oct 12, 2022 at 18:48. Harper . This wire should be either green or copper-colored. Locate the ground screw inside the junction box, which must be machine threaded and green in color. Attach the ground wire to a metal junction box by wrapping the ground conductor around the screw the same direction the screw tightens. This is only necessary when using a metal junction box.

Plastic is cheaper and probably more easier to work with (don’t need to ground the box), but it flexes more - if it’s for myself I’d probably use the metal and make sure it gets solidly mounted so that it doesn’t flex when you insert/unplug cables - but also like others have said, use single or double gang boxes, not these octagon boxes However, if you want to use a box for this, you're going to need something chunkier than a standard-issue junction box to provide enough room to feed fat feeder wires through it. Enter the NEMA-rated pull box; these are the bigger brothers of junction boxes, and are available in sizes from 6"x6" up to "wardrobe". Given that a 1.5" conduit is .

Step 3: Attach the Grounding Wire to the Metal Junction Box. If you are using screws, insert the screw into the pre-drilled hole in the junction box and tighten it until snug. Then, attach the grounding wire to the screw. If you are using clamps, attach the clamp to the junction box and attach the grounding wire to the clamp.Metal junction boxes always need to be grounded, whether you're using NM (non-metallic) plastic-sheathed cable or metallic cable. Metallic cable is self-grounding, as long as the cable is properly . Metal boxes should be used: When metal-sheathed cable or metal conduit is running in or out of the box. For interior exposed application such as in an unfinished basement or mudroom where there's no drywall. You can use a metal box for NM wiring, but special precautions should be taken to ensure proper grounding. Weatherproof Electrical Boxes Electrical - AC & DC - Quicky - ground screw in metal junction box - Quick (stupid) question: I have (2) 12/2 NM-B wires going into a large metal junction box in my basement where they will be connected to (2) 12/2 NM-B wires going to the SEP (each gets 20A breaker). Basically the JB is just to extend the wires (did

@jay613 Self-grounders don't, they have a wiper that touches the side of the mounting screws. However, if you have hard metal-metal contact between yoke and box ears, you don't need self-grounders, you can use cheap 50 cent jobs.

wiring a metal junction box

when to use metal junction box

when to use a metal box

The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in .

when to use metal junktion box|wiring a metal junction box