cnc lathe machining pdf To operate and program a CNC machine, a basic understanding of machining practices and math are necessary. It is also important to be familiar with the machine control and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine. What are the cabinets made of? IKEA cabinets themselves are made of MDF, but there are several different door options. Some are solid wood and some are laminate. My upper white cabinets are MDF, and my lower black-brown cabinets are solid wood. Are IKEA kitchen cabinets expensive? How much do they cost? IKEA kitchen cabinets are a great deal.

0 · cnc turning program examples PDF

1 · cnc turning machine programming PDF

2 · cnc turning cycle program PDF

3 · cnc programming for dummies PDF

4 · cnc programming PDF free download

5 · cnc machine parts list PDF

6 · cnc machine operation manual PDF

7 · cnc lathe manual PDF

What even is a junction box, and how does one work? The Spruce explains that a junction box — also called an electric box — is where two or more electrical wire connections meet into one behind a plastic or metal protective container.

To operate and program a CNC machine, a basic understanding of machining practices and math are necessary. It is also important to be familiar with the machine control and the placement of .

Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine toolsCNC.

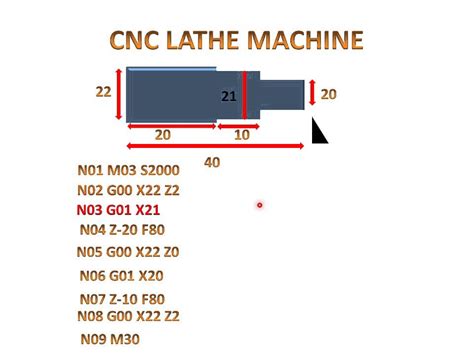

To operate and program a CNC machine, a basic understanding of machining practices and math are necessary. It is also important to be familiar with the machine control and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine.This course describes the basic knowledge of CNC Lathe machining program and how to use the common instructions to the CNC control. The goal of this course is to help you to be able to prepare the basic machining program with referring the .In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.Download for free the PDF version of the Protolabs Network's Engineering Guide to CNC machining. With this 40-page long e-book, learn everything you need to know about CNC machining, from the very basics to advanced design tips.

cnc turning program examples PDF

Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment.

Machine Types Lathe The engine lathe, one of the most productive machine tools, has always been an efficient means of producing round parts (Fig. 4). Most lathes are programmed on two axes. •The X axis controls the cross motion of the cutting tool. Negative X (X-) moves the tool towards the spindleIn order to operate and program a CNC controlled machine, a basic understanding of machining practices and a working knowledge of math is necessary. It is also important to become familiar with the control console and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine.

CNC lathe machines with milling tools. The workpiece is affixed to a rotating spindle while cutting tools remove material from the blank. By combining the elements of CNC lathe machines with milling tools, mill-turning CNC offers high levels of accuracy and geometric versatility, making it great for creatingRefer to “Specifications Manual” of each machine type for stroke, work operation range, tool interference diagram and Q setter•work interference diagram of the machine, which should be fully understood as they are premises for machine operation, programming and tool layout.

cnc turning machine programming PDF

Computer Numerical Control (CNC) mills and lathes. This course bridges the gap between what persons with a technical education know and what they must learn to begin using machine toolsCNC.

To operate and program a CNC machine, a basic understanding of machining practices and math are necessary. It is also important to be familiar with the machine control and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine.This course describes the basic knowledge of CNC Lathe machining program and how to use the common instructions to the CNC control. The goal of this course is to help you to be able to prepare the basic machining program with referring the .In a “CNC” (Computerized Numerical Control) machine, the tool is controlled by a computer and is programmed with a machine code system that enables it to be operated with minimal supervision and with a great deal of repeatability.Download for free the PDF version of the Protolabs Network's Engineering Guide to CNC machining. With this 40-page long e-book, learn everything you need to know about CNC machining, from the very basics to advanced design tips.

cnc turning cycle program PDF

Only authorized and trained individuals may operate CNC equipment. Code examples shown are for illustration purposes only, and are not meant for operation or programming actual equipment.Machine Types Lathe The engine lathe, one of the most productive machine tools, has always been an efficient means of producing round parts (Fig. 4). Most lathes are programmed on two axes. •The X axis controls the cross motion of the cutting tool. Negative X (X-) moves the tool towards the spindle

In order to operate and program a CNC controlled machine, a basic understanding of machining practices and a working knowledge of math is necessary. It is also important to become familiar with the control console and the placement of the keys, switches, displays, etc., that are pertinent to the operation of the machine.CNC lathe machines with milling tools. The workpiece is affixed to a rotating spindle while cutting tools remove material from the blank. By combining the elements of CNC lathe machines with milling tools, mill-turning CNC offers high levels of accuracy and geometric versatility, making it great for creating

cnc programming for dummies PDF

cnc programming PDF free download

cnc machine parts list PDF

MIG welding sheet metal can be harder than TIG, thanks largely to the fact that there’s more heat involved in the process. The number one thing you’re trying to do is minimise the heat input to your metal so that it doesn’t .

cnc lathe machining pdf|cnc programming PDF free download