electric box mooring Our automated mooring solution, MoorMaster™, moors vessels in seconds and keeps vessels in position for safe charging and allows thrusters to be shut off, drastically reducing energy . Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®.

0 · vacuum mooring systems

1 · moormaster vessel overhang

2 · mooring vessel overhang

3 · mooring systems for boats

4 · electric mooring capstan

5 · cavotec vacuum mooring

6 · cavotec mooring machine

A septic tank’s distribution box (or D-box) is a container (typically concrete) that receives the septic tank effluent and re-distributes it into the network of attached drain fields and pipes. To put it simply, its job is to evenly .

Our automated mooring solution, MoorMaster™, moors vessels in seconds and keeps vessels in position for safe charging and allows thrusters to be shut off, drastically reducing energy .Faster, safer and cleaner mooring. MoorMaster™ automated mooring eliminates the need for mooring lines with automated vacuum pads that moor and release vessels in seconds at the .The electric motor can be vertically mounted inside the capstan which permits direct bolting to the deck for ease of installation. The motor can also be horizontally mounted through a right angle .The Marine Electric Mooring Capstan is a specially designed capstan powered by an electric motor, intended for efficient mooring operations. Its primary function is to wind or unwind ropes, cables, or chains that are utilized to secure vessels .

Aicrane positioning mooring systems can be designed to be electrically, hydraulically or diesel driven, with multiple configurations: 4-point mooring, 6-point mooring, 8-point mooring, 12-point mooring, etc. Aicrane Mooring Winches for .

Imagine electric anchor/mooring winches with no hydraulics, motor encoders, gearbox load cell sensors or external controllers. ABB has them today, certified for marine use and speaking deck machinery language.Simple Electronic reconfiguration to match respective terminal. USB downloadable, enhanced diagnostics. Independent systems to ISO 28460. Future-proofed to allow interfaces to external .

how to make electrical junction box ark

The range of KONGSBERG electric mooring capstans are designed specifically for naval vessels. Compact and robust construction means few wearing parts, minimum maintenance and simple .

The electric mooring winch is supplied with CPU-controlled mooring automation to prevent ropes from breaking during port stay. System advantages • Compact design ensuring minimum .This standard range of the SRM type mooring/anchor winches is designed for application on jack-up rigs, barges and other offshore or marine units. These standard winches can be fi tted with .Our automated mooring solution, MoorMaster™, moors vessels in seconds and keeps vessels in position for safe charging and allows thrusters to be shut off, drastically reducing energy consumption. Vessels moored in less than 30 seconds

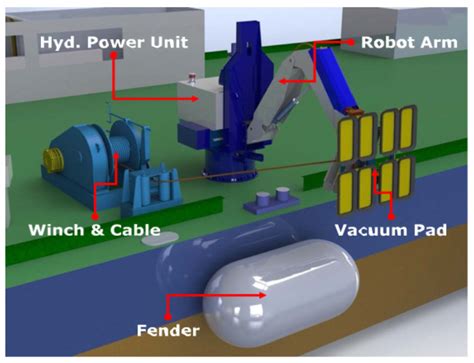

Faster, safer and cleaner mooring. MoorMaster™ automated mooring eliminates the need for mooring lines with automated vacuum pads that moor and release vessels in seconds at the push of a button.

The electric motor can be vertically mounted inside the capstan which permits direct bolting to the deck for ease of installation. The motor can also be horizontally mounted through a right angle gear box to avoid the requirement for a deck penetration.The Marine Electric Mooring Capstan is a specially designed capstan powered by an electric motor, intended for efficient mooring operations. Its primary function is to wind or unwind ropes, cables, or chains that are utilized to secure vessels to docks, buoys, or other mooring points.Aicrane positioning mooring systems can be designed to be electrically, hydraulically or diesel driven, with multiple configurations: 4-point mooring, 6-point mooring, 8-point mooring, 12-point mooring, etc. Aicrane Mooring Winches for Sale.Imagine electric anchor/mooring winches with no hydraulics, motor encoders, gearbox load cell sensors or external controllers. ABB has them today, certified for marine use and speaking deck machinery language.

Simple Electronic reconfiguration to match respective terminal. USB downloadable, enhanced diagnostics. Independent systems to ISO 28460. Future-proofed to allow interfaces to external systems. Easily updatable via USB flash drive. Over 350 LNG Carriers and FSRUs. Over 100 LNG / LPG Condensate Terminals.The range of KONGSBERG electric mooring capstans are designed specifically for naval vessels. Compact and robust construction means few wearing parts, minimum maintenance and simple installation. The baseplate design can be varied to meet specific deck layouts. The electric motor can be vertically mounted inside the capstan which

The electric mooring winch is supplied with CPU-controlled mooring automation to prevent ropes from breaking during port stay. System advantages • Compact design ensuring minimum space required on deck • Three-step or stepless frequency-converted speed control • Automatic load detection by electric load-measuring bolt for mooring operationThis standard range of the SRM type mooring/anchor winches is designed for application on jack-up rigs, barges and other offshore or marine units. These standard winches can be fi tted with several options such as free spooling clutches and spooling gears.Our automated mooring solution, MoorMaster™, moors vessels in seconds and keeps vessels in position for safe charging and allows thrusters to be shut off, drastically reducing energy consumption. Vessels moored in less than 30 secondsFaster, safer and cleaner mooring. MoorMaster™ automated mooring eliminates the need for mooring lines with automated vacuum pads that moor and release vessels in seconds at the push of a button.

The electric motor can be vertically mounted inside the capstan which permits direct bolting to the deck for ease of installation. The motor can also be horizontally mounted through a right angle gear box to avoid the requirement for a deck penetration.The Marine Electric Mooring Capstan is a specially designed capstan powered by an electric motor, intended for efficient mooring operations. Its primary function is to wind or unwind ropes, cables, or chains that are utilized to secure vessels to docks, buoys, or other mooring points.Aicrane positioning mooring systems can be designed to be electrically, hydraulically or diesel driven, with multiple configurations: 4-point mooring, 6-point mooring, 8-point mooring, 12-point mooring, etc. Aicrane Mooring Winches for Sale.

how to make a sheet metal box in solidworks

Imagine electric anchor/mooring winches with no hydraulics, motor encoders, gearbox load cell sensors or external controllers. ABB has them today, certified for marine use and speaking deck machinery language.

Simple Electronic reconfiguration to match respective terminal. USB downloadable, enhanced diagnostics. Independent systems to ISO 28460. Future-proofed to allow interfaces to external systems. Easily updatable via USB flash drive. Over 350 LNG Carriers and FSRUs. Over 100 LNG / LPG Condensate Terminals.

The range of KONGSBERG electric mooring capstans are designed specifically for naval vessels. Compact and robust construction means few wearing parts, minimum maintenance and simple installation. The baseplate design can be varied to meet specific deck layouts. The electric motor can be vertically mounted inside the capstan whichThe electric mooring winch is supplied with CPU-controlled mooring automation to prevent ropes from breaking during port stay. System advantages • Compact design ensuring minimum space required on deck • Three-step or stepless frequency-converted speed control • Automatic load detection by electric load-measuring bolt for mooring operation

how to make a electric box spring

vacuum mooring systems

At the helm of every CNC milling machine is the CNC (Computer Numerical Control) system. It integrates hardware and software to realize automatic control and coordination of the entire machining process. The following are the main components of the CNC system:

electric box mooring|cavotec mooring machine