creo sheet metal practice drawings pdf SHEET METAL CAD EXERCISES - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document lists 40 sheet metal CAD exercises numbered from 1 to 40 without providing any details about the content or . Trick Tools offers high performance metal fabrication equipment and metal working tools like tube benders, notchers, saws, English wheels, and sheet metal brakes

0 · sheet metal design practice PDF

1 · sheet metal creo parametric

2 · creo sheet metal tutorial PDF

3 · creo sheet metal tutorial

4 · creo sheet metal projects

5 · creo sheet metal basics

6 · creo practice sheet metal models

7 · creo parametric sheet metal tutorial

Find Aluminum sheet metal at Lowe's today. Shop sheet metal and a variety of hardware products online at Lowes.com.

In general, it is most effective to create sheet metal designs in their bent state and then unbend them for flat pattern geometry. Create . See moreYou can add flat walls, extruded walls, swept walls, extends, twists, and merged walls. They are attached to the edges on the part. Except for . See more

metal wendy houses

When manipulating thin-walled models (like sheet metal or die-cast parts) it is often difficult to select the thin side surfaces when you wish to orient the view. Because of the thinness of a sheet metal part, using edges for orienting the part is more convenient . See moreWhen you create a flat, extruded, or partial wall, you must specify a bend table. If you use the Use Radius option when creating a flat, extruded, partial, or swept wall, you must also specify the . See moreSHEET METAL CAD EXERCISES - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document lists 40 sheet metal CAD exercises numbered from 1 to 40 without providing any details about the content or .

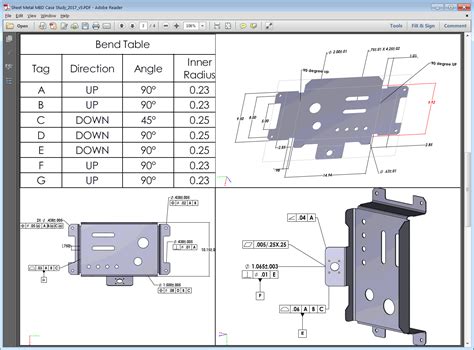

Specifically, topics covered include: flat patterns, deformation allowance, bend tables, working in both flat and "as designed" states, and full associativity between part, drawing and flat state. .

metal window box lowes

Lesson 1 Introduction WelcometoselfpacedtrainingforSolidEdge.Thiscourseisdesignedtoeducateyou . This method of working with sheet metal is to create the model within sheet metal from a number of flat pieces joined together. The alternative is to create a solid first then shell .This document provides an overview of a training course on sheetmetal design using Creo Parametric. The course objectives are to teach students how to create primary and secondary sheetmetal walls, apply various features, generate flat . Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (1) Level: basic, Year 10/11 Contribution to D&T, Maths, Science: design and creation .

metal wrap around shelf brackets

In Creo Parametric, the parametric part modeling process involves the following steps: 1. Set up Units and Basic Datum Geometry. 2. Determine the type of the base feature, the first solid feature, of the design. Note that Extrude, Revolve, .

This document presents a collection of CAD and CAM practice drawings for beginners. It contains 100 3D CAD practice drawings, 4 assembly practice drawings, 3 GD&T practice drawings, 20 sheet metal practice drawings, 73 .This training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features. On completion of this course, you .Sheet Metal Design Using Pro/SHEETMETAL In general, it is most effective to create sheet metal designs in their bent state and then unbend them for flat pattern geometry. Create your design as per your design intent. It is not necessary to create the design in the order of manufacture. Sheet metal parts can beSHEET METAL CAD EXERCISES - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document lists 40 sheet metal CAD exercises numbered from 1 to 40 without providing any details about the content or objectives of each individual exercise.

Specifically, topics covered include: flat patterns, deformation allowance, bend tables, working in both flat and "as designed" states, and full associativity between part, drawing and flat state. Ensure you have the sheetmetal module attached to .

Lesson 1 Introduction WelcometoselfpacedtrainingforSolidEdge.Thiscourseisdesignedtoeducateyou intheuseofSolidEdge.Thecourseisself-pacedandcontainsinstructionfollowed

This method of working with sheet metal is to create the model within sheet metal from a number of flat pieces joined together. The alternative is to create a solid first then shell it before opening the sheet metal module. Create and name a new Sheetmetal part.This document provides an overview of a training course on sheetmetal design using Creo Parametric. The course objectives are to teach students how to create primary and secondary sheetmetal walls, apply various features, generate flat patterns, and create detailed drawings.

sheet metal design practice PDF

sheet metal creo parametric

Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (1) Level: basic, Year 10/11 Contribution to D&T, Maths, Science: design and creation of nets for construction of containers, nets of geometrical shapes. This method of working with sheet metal is to create a solid first thenIn Creo Parametric, the parametric part modeling process involves the following steps: 1. Set up Units and Basic Datum Geometry. 2. Determine the type of the base feature, the first solid feature, of the design. Note that Extrude, Revolve, or Sweep operations are the most common types of base features. 3.

This document presents a collection of CAD and CAM practice drawings for beginners. It contains 100 3D CAD practice drawings, 4 assembly practice drawings, 3 GD&T practice drawings, 20 sheet metal practice drawings, 73 turning practice drawings, and 32 milling practice drawings.

creo sheet metal tutorial PDF

This training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features. On completion of this course, you will have acquired the skills to confidently manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.Sheet Metal Design Using Pro/SHEETMETAL In general, it is most effective to create sheet metal designs in their bent state and then unbend them for flat pattern geometry. Create your design as per your design intent. It is not necessary to create the design in the order of manufacture. Sheet metal parts can beSHEET METAL CAD EXERCISES - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document lists 40 sheet metal CAD exercises numbered from 1 to 40 without providing any details about the content or objectives of each individual exercise.

Specifically, topics covered include: flat patterns, deformation allowance, bend tables, working in both flat and "as designed" states, and full associativity between part, drawing and flat state. Ensure you have the sheetmetal module attached to .

Lesson 1 Introduction WelcometoselfpacedtrainingforSolidEdge.Thiscourseisdesignedtoeducateyou intheuseofSolidEdge.Thecourseisself-pacedandcontainsinstructionfollowed This method of working with sheet metal is to create the model within sheet metal from a number of flat pieces joined together. The alternative is to create a solid first then shell it before opening the sheet metal module. Create and name a new Sheetmetal part.

This document provides an overview of a training course on sheetmetal design using Creo Parametric. The course objectives are to teach students how to create primary and secondary sheetmetal walls, apply various features, generate flat patterns, and create detailed drawings. Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (1) Level: basic, Year 10/11 Contribution to D&T, Maths, Science: design and creation of nets for construction of containers, nets of geometrical shapes. This method of working with sheet metal is to create a solid first thenIn Creo Parametric, the parametric part modeling process involves the following steps: 1. Set up Units and Basic Datum Geometry. 2. Determine the type of the base feature, the first solid feature, of the design. Note that Extrude, Revolve, or Sweep operations are the most common types of base features. 3.

This document presents a collection of CAD and CAM practice drawings for beginners. It contains 100 3D CAD practice drawings, 4 assembly practice drawings, 3 GD&T practice drawings, 20 sheet metal practice drawings, 73 turning practice drawings, and 32 milling practice drawings.

metal window boxes nz

metal work fabrications

Okuma CNC is a machining center manufacturer that makes machines including CNC lathe machine tools, CNC mills, turn-mill, grinders, and laser cutters. With the vast majority of used Okuma CNC machines available, you are sure to find the right Okuma corporation branded CNC machine for your shop or machine operation needs.

creo sheet metal practice drawings pdf|sheet metal design practice PDF