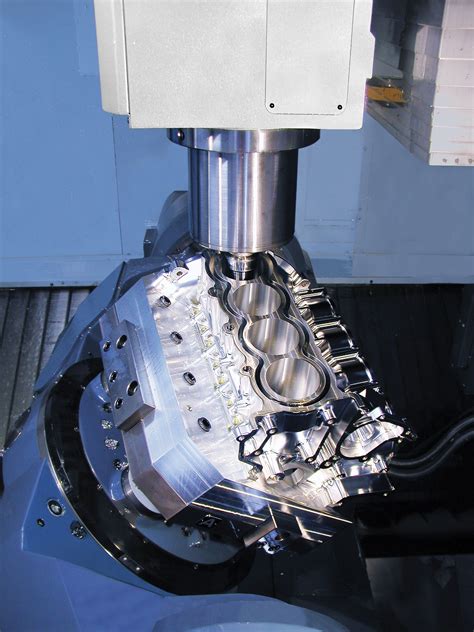

cnc machine making engine block The B4250 is a complete turn-key CNC engine block machining package. We supply the accessories, tooling and the training so you will be blueprinting and machining blocks in no time. The B4250 will CNC blueprint an engine block . Any plenums/square duct over 12x12x12 should be a heavier gauge than 30, even when cross broken they tend to have duct banging issues because the metal isn't rigid enough IMO. All our fabricated duct is 24/26 gauge.

0 · rottler machine shop equipment

1 · engine block machining near me

2 · engine block machine work cost

3 · engine block machine shop

4 · cnc engine boring machine

5 · cnc engine block machining center

6 · cnc engine block boring machine

7 · best engine block boring machine

If you have a set of calipers you can measure the thickness of the existing metal and then order what you need. Here's some of the common gauges and corresponding thickness of sheet steel: GA.

The B4250 is a complete turn-key CNC engine block machining package. We supply the accessories, tooling and the training so you will be blueprinting and machining blocks in no time. The B4250 will CNC blueprint an engine block .

CENTROID designs and manufactures 5-axis CNC machining centers designed for cylinder head porting, block work and parts, and 4-axis machine tools for engine block machining and rebuilding and parts.

rottler machine shop equipment

engine block machining near me

Common machining tasks on an engine block involve deck resurfacing, cylinder overboring (to save a block or to increase displacement) and cylinder honing. For high-performance and . Blueprinting an engine block is the beginning step, and shops like CNC-Motorsports use the factory’s dimensions and recommended specifications to machine the .Use and operator interface to lead the customer through the block boring and surfacing process without any knowledge of running a CNC control. Have the fastest floor to floor time possible on any CNC boring millEngine block machining involves precision processes to shape and refine the surfaces and features of an engine block, the main structure of an internal combustion engine. This can include milling, honing, boring, and other .

We offer dedicated automatic, manual and CNC Engine Block surfacers, as well as multi-purpose machining centers that boast block surfacing capabilities as just one of many other machine .In today's advanced manufacturing industry, the use of computer numerical control (CNC) machines has revolutionized the production of engine blocks. This technology, combined with .Prestige Motorsports is proud to announce our in-house CNC block machining options for customers! With our Centroid A560 CNC machine and our new Rottler HX85AX hone, not only do we machine our blocks to our high specifications, .Complete turn-key CNC engine block machining package. We supply the accessories, tooling and the training so you will be blueprinting and machining blocks in no time. The Centroid CNC will blueprint an engine block faster and more accurately than the competition.

The B4250 is a complete turn-key CNC engine block machining package. We supply the accessories, tooling and the training so you will be blueprinting and machining blocks in no time. The B4250 will CNC blueprint an engine block faster and more accurately than the competition.CENTROID designs and manufactures 5-axis CNC machining centers designed for cylinder head porting, block work and parts, and 4-axis machine tools for engine block machining and rebuilding and parts.Common machining tasks on an engine block involve deck resurfacing, cylinder overboring (to save a block or to increase displacement) and cylinder honing. For high-performance and racing applications, this also involves an at-tempt to accurize a block (an aspect of blue-printing).

Blueprinting an engine block is the beginning step, and shops like CNC-Motorsports use the factory’s dimensions and recommended specifications to machine the engine block and properly reflect those elements.Use and operator interface to lead the customer through the block boring and surfacing process without any knowledge of running a CNC control. Have the fastest floor to floor time possible on any CNC boring millEngine block machining involves precision processes to shape and refine the surfaces and features of an engine block, the main structure of an internal combustion engine. This can include milling, honing, boring, and other machining operations to .

We offer dedicated automatic, manual and CNC Engine Block surfacers, as well as multi-purpose machining centers that boast block surfacing capabilities as just one of many other machine operations. Featuring ability to Deck blocks, Surface heads, true .In today's advanced manufacturing industry, the use of computer numerical control (CNC) machines has revolutionized the production of engine blocks. This technology, combined with precision engineering, has transformed the way engine blocks are manufactured.Prestige Motorsports is proud to announce our in-house CNC block machining options for customers! With our Centroid A560 CNC machine and our new Rottler HX85AX hone, not only do we machine our blocks to our high specifications, but we also offer the same high quality machine work to you for your block machining needs.Complete turn-key CNC engine block machining package. We supply the accessories, tooling and the training so you will be blueprinting and machining blocks in no time. The Centroid CNC will blueprint an engine block faster and more accurately than the competition.

engine block machine work cost

The B4250 is a complete turn-key CNC engine block machining package. We supply the accessories, tooling and the training so you will be blueprinting and machining blocks in no time. The B4250 will CNC blueprint an engine block faster and more accurately than the competition.CENTROID designs and manufactures 5-axis CNC machining centers designed for cylinder head porting, block work and parts, and 4-axis machine tools for engine block machining and rebuilding and parts.Common machining tasks on an engine block involve deck resurfacing, cylinder overboring (to save a block or to increase displacement) and cylinder honing. For high-performance and racing applications, this also involves an at-tempt to accurize a block (an aspect of blue-printing). Blueprinting an engine block is the beginning step, and shops like CNC-Motorsports use the factory’s dimensions and recommended specifications to machine the engine block and properly reflect those elements.

Use and operator interface to lead the customer through the block boring and surfacing process without any knowledge of running a CNC control. Have the fastest floor to floor time possible on any CNC boring millEngine block machining involves precision processes to shape and refine the surfaces and features of an engine block, the main structure of an internal combustion engine. This can include milling, honing, boring, and other machining operations to .

We offer dedicated automatic, manual and CNC Engine Block surfacers, as well as multi-purpose machining centers that boast block surfacing capabilities as just one of many other machine operations. Featuring ability to Deck blocks, Surface heads, true .

In today's advanced manufacturing industry, the use of computer numerical control (CNC) machines has revolutionized the production of engine blocks. This technology, combined with precision engineering, has transformed the way engine blocks are manufactured.

engine block machine shop

cnc engine boring machine

cnc engine block machining center

cnc engine block boring machine

Adjustable soft close doors on all cabinets; 24-gauge steel with welded construction provides exceptional durability and strength; Durable powder coat finish offers protection and corrosion resistance; Cabinets ship pre-assembled for ease of set up; Integrated storage bin system holds up .

cnc machine making engine block|engine block machining near me