converting inventor part to sheet metal Autodesk® Inventor® has tools for creating sheet metal-specific features that follow a manufacturing standard, ensuring your ability to flatten your 3D model. (Guipé refers to the thread composed of metallic fibers wrapped around a fiber core.) Lamé is classically gold, silver, or copper in color. Today, most mass-market lamé uses synthetic metallized polyester film such as Mylar instead of true metallic fiber, so it is available in any color.

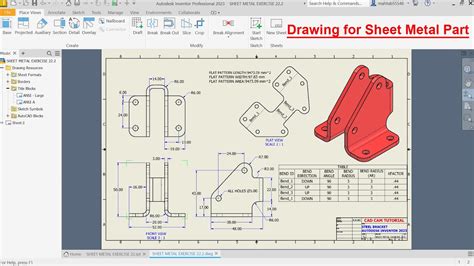

0 · sheet metal drawing in inventor

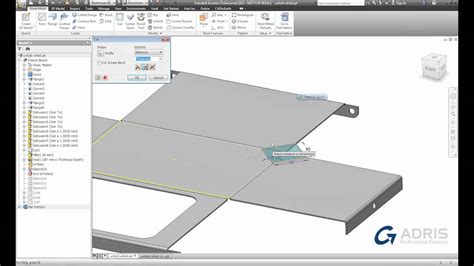

1 · inventor unfold sheet metal

2 · inventor sheet metal tutorial pdf

3 · inventor sheet metal exercises pdf

4 · inventor sheet metal defaults

5 · inventor change sheet metal thickness

6 · edit sheet metal rule inventor

7 · autodesk inventor sheet metal tutorial

DI stands for direct injection. That is exactly what a DI box allows. You may hear them referred to as direct boxes too. With a direct box, you don’t need to haul an amp around since it’s designed to convert the signal into a balanced signal that goes through an XLR (microphone) output.

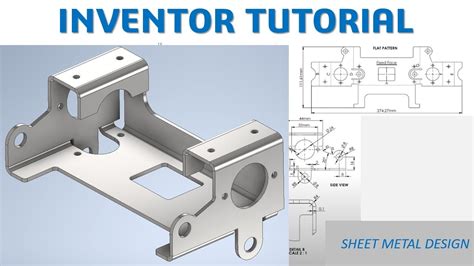

Time to get familiar with sheet metal environment - it is easy. My part - your part. Notice the transitions. There are two different methods using Lofted Flange - Die Formed and Press Brake Formed. Try both and use the one that will actually be used to manufacture the part. Short overview of how to convert a standard part to sheet metal in Autodesk Inventor, so it can be unfolded as well. .more. For consultation regarding Autodesk Inventor, please contact.

Autodesk® Inventor® has tools for creating sheet metal-specific features that follow a manufacturing standard, ensuring your ability to flatten your 3D model.

I'm wondering if there is an easy way to convert this standard Inventor 2015 part to a sheet metal part so I can create a flat pattern. I've had some light sheet metal training years . Learn how to convert parts into sheet metal designs and flatten them accurately using Autodesk Inventor. Discover the process step-by-step.

To convert a standard Inventor part to a sheet metal part use the Convert to Sheet Metal function, available in the 3D Model tab. When converting, Inventor will ask to select the . converts solid parts to sheet metal parts in a single click. However, you can achieve this by following a manual process. Here are the general steps to conve.

sheet metal drawing in inventor

Autodesk Inventor allows for converting models to sheet metal. Which means, regardless where the model geometry originates, you can convert it to sheet metal, add sheet metal features, and generate the flat pattern.

Create a regular part with a uniform thickness, and then convert it to a sheet metal part. Specifying a part as sheet metal displays the Sheet Metal tab, and adds sheet metal-specific . TruNest accepts Inventor files as input, and expects them to be sheet metal flat parts (I think). We exported our Fusion file to Inventor (using Autodesk Cloud). Then the .

Time to get familiar with sheet metal environment - it is easy. My part - your part. Notice the transitions. There are two different methods using Lofted Flange - Die Formed and Press Brake Formed. Try both and use the one that will actually be used to manufacture the part.

Short overview of how to convert a standard part to sheet metal in Autodesk Inventor, so it can be unfolded as well. .more. For consultation regarding Autodesk Inventor, please contact.

inventor unfold sheet metal

Autodesk® Inventor® has tools for creating sheet metal-specific features that follow a manufacturing standard, ensuring your ability to flatten your 3D model.

I'm wondering if there is an easy way to convert this standard Inventor 2015 part to a sheet metal part so I can create a flat pattern. I've had some light sheet metal training years ago, mostly unused and forgotten. The part was created from a thickened surface quilt in a multibody solid. Learn how to convert parts into sheet metal designs and flatten them accurately using Autodesk Inventor. Discover the process step-by-step.

To convert a standard Inventor part to a sheet metal part use the Convert to Sheet Metal function, available in the 3D Model tab. When converting, Inventor will ask to select the base face. Inventor should then recognize the thickness of the component. converts solid parts to sheet metal parts in a single click. However, you can achieve this by following a manual process. Here are the general steps to conve.

Autodesk Inventor allows for converting models to sheet metal. Which means, regardless where the model geometry originates, you can convert it to sheet metal, add sheet metal features, and generate the flat pattern.Create a regular part with a uniform thickness, and then convert it to a sheet metal part. Specifying a part as sheet metal displays the Sheet Metal tab, and adds sheet metal-specific parameters to the parameters list. Conversely, you can .

TruNest accepts Inventor files as input, and expects them to be sheet metal flat parts (I think). We exported our Fusion file to Inventor (using Autodesk Cloud). Then the following script is meant convert each part from a solid part to a . Time to get familiar with sheet metal environment - it is easy. My part - your part. Notice the transitions. There are two different methods using Lofted Flange - Die Formed and Press Brake Formed. Try both and use the one that will actually be used to manufacture the part. Short overview of how to convert a standard part to sheet metal in Autodesk Inventor, so it can be unfolded as well. .more. For consultation regarding Autodesk Inventor, please contact. Autodesk® Inventor® has tools for creating sheet metal-specific features that follow a manufacturing standard, ensuring your ability to flatten your 3D model.

inventor sheet metal tutorial pdf

I'm wondering if there is an easy way to convert this standard Inventor 2015 part to a sheet metal part so I can create a flat pattern. I've had some light sheet metal training years ago, mostly unused and forgotten. The part was created from a thickened surface quilt in a multibody solid. Learn how to convert parts into sheet metal designs and flatten them accurately using Autodesk Inventor. Discover the process step-by-step.

To convert a standard Inventor part to a sheet metal part use the Convert to Sheet Metal function, available in the 3D Model tab. When converting, Inventor will ask to select the base face. Inventor should then recognize the thickness of the component. converts solid parts to sheet metal parts in a single click. However, you can achieve this by following a manual process. Here are the general steps to conve. Autodesk Inventor allows for converting models to sheet metal. Which means, regardless where the model geometry originates, you can convert it to sheet metal, add sheet metal features, and generate the flat pattern.Create a regular part with a uniform thickness, and then convert it to a sheet metal part. Specifying a part as sheet metal displays the Sheet Metal tab, and adds sheet metal-specific parameters to the parameters list. Conversely, you can .

cnc milling drawing parts supplier

cnc milling aluminum heat sink manufacturers

Box junctions. These have criss-cross yellow lines painted on the road ( download ‘Road markings’ ). You MUST NOT enter the box until your exit road or lane is clear.

converting inventor part to sheet metal|inventor sheet metal exercises pdf