3 4 5 axis cnc machining The main difference between 3-axis, 4-axis and 5-axis CNC machining is the range of motion. On 3-axis CNC mills, the cutting tool orientation remains constant throughout the cutting path, while on 4- and 5-axis mills, the . Best CNC Router Overall: MYSWEETY CNC Pro Engraver Machine Shop Now Runner Up: SainSmart Genmitsu CNC Router Machine Shop Now Honorable Mention: Genmitsu CNC Router Kit Shop Now

0 · what is 5 axis milling

1 · what does 5 axis mean

2 · small 5 axis cnc mill

3 · benefits of 5 axis machining

4 · 5 axis trunnion machining

5 · 5 axis machining explained

6 · 5 axis machining basics

7 · 5 axis cnc explained

The average hourly wage for a Metal Fabricator in the United States is $20 as of November 01, 2024, but the salary range typically falls between $18 and $24.

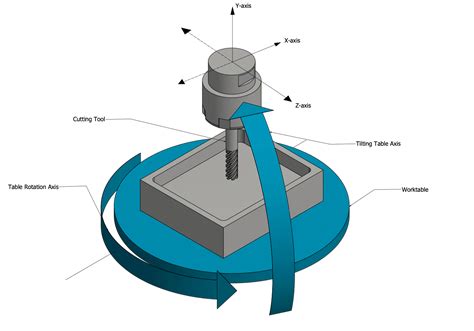

The main difference between 3-axis, 4-axis and 5-axis CNC machining is the range of motion. On 3-axis CNC mills, the cutting tool orientation remains constant throughout the cutting path, while on 4- and 5-axis mills, the .Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert . The main difference between 3-axis, 4-axis and 5-axis CNC machining is the range of motion. On 3-axis CNC mills, the cutting tool orientation remains constant throughout the cutting path, while on 4- and 5-axis mills, the workpiece can also move.Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert insights to help you select the ideal setup for applications from simple parts to .

3 axis machines are the most basic with a spindle that moves up and down from side to side. 4 axis machines add a rotating axis, offering greater efficiency and flexibility. 5 axis CNC machines add a second rotating axis, offering .

3-axis, 4-axis, and 5-axis CNC machines cater to a specific set of users. Each of these machines come at a specific price point and with its own applications. With the information provided above, you can now easily choose between these three options for your next project. The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two parts, the more complex the geometry of the final machined part can be. In this guide, we’ll discuss how CNC machines are able to make complex shapes using multiple axes of travel, how these directions are defined, and what that means for your product development goals.

3 4 5 axis machining is essential in modern manufacturing, allowing for precision and flexibility in creating complex parts. To quickly grasp the differences: 3-Axis Machining: Uses X, Y, and Z axes. Ideal for simpler, planar designs. 4-Axis Machining: Adds an A-axis (rotation around X-axis). Better for intricate profiles.

Five axis CNC machining is an advanced CNC machining technology that adds two rotation axes (usually referred to as A-axis and C-axis) to the traditional three-axis (X, Y, Z), allowing the workpiece or tool to move or rotate in five different directions. In the case of large production batches, 3-axis CNC machining can offset the advantages of 4-axis and 5-axis CNC machining by employing custom quick fixtures, automated clamping methods, and other techniques to minimize setup time. Knowing the difference between 3, 4, and 5-axis machines is the first step towards understanding which machine is right for you. At Rapid Axis, we have 3, 4, and 5-axis CNC machines on our shop floor. We have the machinery to . The main difference between 3-axis, 4-axis and 5-axis CNC machining is the range of motion. On 3-axis CNC mills, the cutting tool orientation remains constant throughout the cutting path, while on 4- and 5-axis mills, the workpiece can also move.

Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert insights to help you select the ideal setup for applications from simple parts to . 3 axis machines are the most basic with a spindle that moves up and down from side to side. 4 axis machines add a rotating axis, offering greater efficiency and flexibility. 5 axis CNC machines add a second rotating axis, offering . 3-axis, 4-axis, and 5-axis CNC machines cater to a specific set of users. Each of these machines come at a specific price point and with its own applications. With the information provided above, you can now easily choose between these three options for your next project. The main difference between 3-axis, 4-axis and 5-axis machining is the complexity of the movement both the workpiece and the cutting tool can move through, relative to each other. The more complex the motion of the two parts, the more complex the geometry of the final machined part can be.

In this guide, we’ll discuss how CNC machines are able to make complex shapes using multiple axes of travel, how these directions are defined, and what that means for your product development goals.

what is 5 axis milling

what does 5 axis mean

3 4 5 axis machining is essential in modern manufacturing, allowing for precision and flexibility in creating complex parts. To quickly grasp the differences: 3-Axis Machining: Uses X, Y, and Z axes. Ideal for simpler, planar designs. 4-Axis Machining: Adds an A-axis (rotation around X-axis). Better for intricate profiles.

Five axis CNC machining is an advanced CNC machining technology that adds two rotation axes (usually referred to as A-axis and C-axis) to the traditional three-axis (X, Y, Z), allowing the workpiece or tool to move or rotate in five different directions.

In the case of large production batches, 3-axis CNC machining can offset the advantages of 4-axis and 5-axis CNC machining by employing custom quick fixtures, automated clamping methods, and other techniques to minimize setup time.

small 5 axis cnc mill

benefits of 5 axis machining

Green, green with a yellow stripe, and bare copper wires can only be used for grounding purposes. A ground wire can never be used as a neutral, even though it connects to the same bus at the main.

3 4 5 axis cnc machining|5 axis machining explained