blueprint reading for cnc machines Blueprints for CNC machines typically incorporate information regarding the specific machining operations and tooling requirements. In this section, we will cover common machining . the metal stars you see on the outside of houses and barns — most commonly found in the more rural parts of the U.S. — actually have a deeper meaning. For one thing, those particular stars.

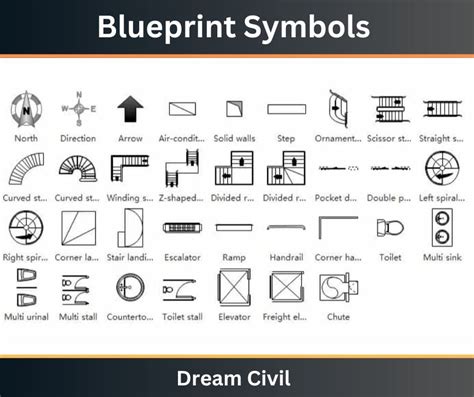

0 · symbols in blueprints

1 · machining blueprint symbols and meanings

2 · how to read blueprint symbols

3 · cnc drawing symbols

4 · blueprint symbols chart

5 · blueprint symbols and meanings

6 · blueprint lines and symbols

7 · blueprint drawing symbols

Roof and building specifications often use “gauge” when stating the required material thickness. A structural engineer will call for 20 gauge steel deck, for example, or a roof consultant will specify 24 gauge steel panels to be used in a standing seam metal roof.

Learning to read blueprints can be hard. That’s why we’ve broken down the process into bite size chunks. All of the basic components of an engineering drawing are .CNC Programming; Blueprint Reading; Measuring & Quality Control; Machine .A guide to all of the keyboard shortcuts for inserting each blueprint symbol into your .

Blueprints for CNC machines typically incorporate information regarding the specific machining operations and tooling requirements. In this section, we will cover common machining .

Learn the basics of blueprint reading including dimensions, zero points, and more Regardless of the reasons, modern machinists still need to master how to read physical blueprints. To help, we’ve broken the process down into five easy steps. Start with the key! Reading blueprints isn’t meant to require some .

Reading a blueprint accurately is extremely important in the machining industry. If you can’t decipher a print or flip your views (more on that later), you’ll have a hard time .

Part 1 of a series of videos presenting a free online machine shop program (lessons) for novice machinists. More specifically, this video introduces us to th. In this blog post, we’ll explain how to read blueprints for CNC machines and understand blueprints are critical for efficient production. In manufacturing processes, blueprints provide an invaluable resource for .In the world of CNC machining, blueprint symbols play a crucial role in communicating design requirements and specifications. Understanding these symbols is essential for both machinists .

Blueprint reading is crucial for precision in manufacturing. Understanding symbols, dimensions, and annotations on CNC blueprints is essential for effective communication. Analyzing views, sections, and . To read blueprints for CNC machines, follow these steps: Start by understanding the blueprint’s symbols and abbreviations. Identify the part’s dimensions and tolerances. Look for special instructions like surface finish or . Learning to read blueprints can be hard. That’s why we’ve broken down the process into bite size chunks. All of the basic components of an engineering drawing are detailed below with links throughout to give you more info on each subject.

Blueprints for CNC machines typically incorporate information regarding the specific machining operations and tooling requirements. In this section, we will cover common machining operations, including drilling, milling, turning, and threading, and discuss how they are . Learn the basics of blueprint reading including dimensions, zero points, and more Regardless of the reasons, modern machinists still need to master how to read physical blueprints. To help, we’ve broken the process down into five easy steps. Start with the key! Reading blueprints isn’t meant to require some obscure ritual or a complicated set of mathematical calculations.

Reading a blueprint accurately is extremely important in the machining industry. If you can’t decipher a print or flip your views (more on that later), you’ll have a hard time meeting the part requirements. The first thing to look at is the job description box.Part 1 of a series of videos presenting a free online machine shop program (lessons) for novice machinists. More specifically, this video introduces us to th.

In this blog post, we’ll explain how to read blueprints for CNC machines and understand blueprints are critical for efficient production. In manufacturing processes, blueprints provide an invaluable resource for engineers who need to .In the world of CNC machining, blueprint symbols play a crucial role in communicating design requirements and specifications. Understanding these symbols is essential for both machinists and designers, as they provide a common language for technical drawings and blueprints. Blueprint reading is crucial for precision in manufacturing. Understanding symbols, dimensions, and annotations on CNC blueprints is essential for effective communication. Analyzing views, sections, and dimensions helps translate blueprints into actionable instructions for the CNC machine. To read blueprints for CNC machines, follow these steps: Start by understanding the blueprint’s symbols and abbreviations. Identify the part’s dimensions and tolerances. Look for special instructions like surface finish or heat treatment. Analyze the blueprint’s views and projections to visualize the part.

Learning to read blueprints can be hard. That’s why we’ve broken down the process into bite size chunks. All of the basic components of an engineering drawing are detailed below with links throughout to give you more info on each subject.Blueprints for CNC machines typically incorporate information regarding the specific machining operations and tooling requirements. In this section, we will cover common machining operations, including drilling, milling, turning, and threading, and discuss how they are . Learn the basics of blueprint reading including dimensions, zero points, and more

Regardless of the reasons, modern machinists still need to master how to read physical blueprints. To help, we’ve broken the process down into five easy steps. Start with the key! Reading blueprints isn’t meant to require some obscure ritual or a complicated set of mathematical calculations. Reading a blueprint accurately is extremely important in the machining industry. If you can’t decipher a print or flip your views (more on that later), you’ll have a hard time meeting the part requirements. The first thing to look at is the job description box.Part 1 of a series of videos presenting a free online machine shop program (lessons) for novice machinists. More specifically, this video introduces us to th.

In this blog post, we’ll explain how to read blueprints for CNC machines and understand blueprints are critical for efficient production. In manufacturing processes, blueprints provide an invaluable resource for engineers who need to .In the world of CNC machining, blueprint symbols play a crucial role in communicating design requirements and specifications. Understanding these symbols is essential for both machinists and designers, as they provide a common language for technical drawings and blueprints.

Blueprint reading is crucial for precision in manufacturing. Understanding symbols, dimensions, and annotations on CNC blueprints is essential for effective communication. Analyzing views, sections, and dimensions helps translate blueprints into actionable instructions for the CNC machine.

symbols in blueprints

machining blueprint symbols and meanings

how to read blueprint symbols

There are several careers in the metal industry that involve handling, managing or creating metal products. Some of these jobs require cutting or welding materials, while others require managing a company's operations.

blueprint reading for cnc machines|blueprint lines and symbols