cnc machine tool maintenance Established in 1985, Billor McDowell provides repairs on all makes and models of CNC machine tools. We are recognized throughout the Southern United States for responsive service by professional technicians that have an exceptional ability to diagnose and repair any problem that you may have with your machine tool.

$175.00

0 · preventive maintenance for lathe machine

1 · preventative maintenance for cnc machines

2 · milling machine preventive maintenance checklist

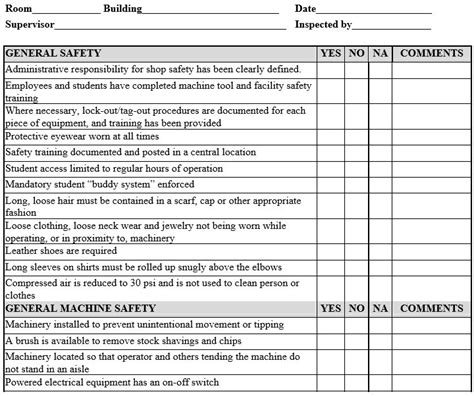

3 · lathe machine preventive maintenance checklist

4 · cnc maintenance checklist pdf

5 · cnc machine maintenance training pdf

6 · cnc machine maintenance checklist pdf

7 · cnc machine maintenance checklist

Check out our antique metal button push selection for the very best in unique or custom, handmade pieces from our buttons shops.

Establishing a consistent maintenance routine is essential to keep your CNC mill running at peak performance. A daily cleaning schedule helps remove debris and residue that could interfere with the machine's precision and functionality. Additionally, inspecting key components such as .Learn the importance of preventive maintenance for CNC machines. Discover best practices, checklists and how ATS can support your maintenance needs.

Mike has been servicing CNC machines for Action since 2010. He is also responsible for the parts and component repair services we offer. 724-561-3996 (call/text)We service and repair all CNC machines including lathes, mills, 5 axis, gantry, horizontal boring mills, and vertical turning lathes. top of page . V-Tech Machine Tool Repair. 5140 Main St. Unit 1. New Port Richey, FL 34652 .

Buy the right maintenance tools for the job!!...Find Quality Maintenance repair tools for repairing and troubleshooting CNC's, machinery and equipment. Every service technician should have these maintenance tools! We've done the work to find the right tool for the job - CNC Specialty Store. Can't find the right tool? Call us. 414-881-449 3Established in 1985, Billor McDowell provides repairs on all makes and models of CNC machine tools. We are recognized throughout the Southern United States for responsive service by professional technicians that have an exceptional ability to diagnose and repair any problem that you may have with your machine tool.

Established in 1985, Billor McDowell provides repairs on all makes and models of CNC machine tools. We are recognized throughout the Southern United States for responsive service by professional technicians that have an exceptional ability to diagnose and repair any problem that you may have with your machine tool.Diversified Technical Services (DTS) specializes in CNC machine tool repair, maintenance, and calibration for machine tools of all makes and models. While our repair capabilities include mechanical, hydraulic and pneumatic devices of every description, our strength lies in our ability to diagnose and correct difficult electrical, electronic and .

Designed for easy reference, we also provide a downloadable PDF guide that you can use as a reference tool in your maintenance routine. Whether you are an experienced CNC machine operator or a beginner, this checklist will help you keep your machine running smoothly and minimize downtime. . Section 4: Daily CNC Machine Maintenance Checklist .

CNC Machine Tools Ltd is one of the largest companies specialising in the servicing, repair and maintenance of all types of machines.. . breakdown repair, repair& rebuild and CNC machine servicing. Quality and Cost Effective. CNC Machine Tools Ltd can provide the support for small, medium and high capacity facilities regarding machine repair .As the owner of Mr. Machine Tool CNC Service and Repair, I bring nearly 2 decades of FSE experience providing service and support for the Aerospace, Medical, and Semiconductor industries. I have worked for OE manufacturers including Mazak and Makino, and have specialized in machine crash recovery, installation, and spindle repair. .CNC Servicing. Having a specialist CNC service provider on hand to ensure the productivity of your CNC machine tools is vital. A team such as MTT will schedule machine tool maintenance and servicing for your machines to assure they are running consistently.CNC Machine Preventative Maintenance and Service. . Prime Tool Rebuilders was able to repair our CNC mill at a fraction of the price that OEM trained technicians quoted to perform an unnecessary machine control retrofit. Would recommend and call on Prime Tool Rebuilders again in the future if needed.

We are a full service CNC repair company serving the Pittsburgh and surrounding area. Our techs have a combined 50+ years of experience in CNC repair. We offer repair, preventative maintenance, inspections, safety audits, parts, batteries, drive and motor rebuilds, etc.

5 axis cnc machining surrey

preventive maintenance for lathe machine

CNC machine tool (CNCMT), as the mother machine of industry, is one type of important manufacturing equipment [1]. The performance and reliability of CNCMT determines the quality of products it has processed.preventative maintenance. houston texas cnc repair of most major brands 10 service technicians with over 200 years of experience. our guarantee! we fix it or the labor is free! cnc machine tool troubleshooting & repair. supporting all major brands with fanuc, siemens, heidenhain, mitsubishi, mazatrol, osp, fadal, milltronics & haas controls

Hibernian Machine Tool Responsive, excellent CNC machine repair service in New Hampshire and New England. Schedule Service: (603) 554-5647. Free Telephone Support: (978) 660-0332. Home; Service; Parts; Maintenance; .CNC Machine Tool Maintenance Technician jobs. Sort by: relevance - date. 800+ jobs. CNC Maintenance Technician III. Hiring multiple candidates. STROHWIG INDUSTRIES 3.3. Richfield, WI 53076. - an hour. Full-time. Monday to Friday +7. Easily apply.Research on the Maintenance Strategy of CNC Machine Tool 585 2 Regular Maintenance of CNC Machine Tool The so-called regular maintenance, as shown in Fig. 1, is a preventive repair in accordance with the time interval which is regarded as regular repair. If the system is repaired between the time intervals, the repaired time will be the initial .

CNC Machine Tool Repair . Here you can find problems, solutions, and related repair information for: Replacement procedures; Repair procedures; Machine inspections; Axis alignment repair; Tool changer adjustments and repair; Parameter .

By keeping the coolant clean and at the correct concentration, you ensure that your CNC mill operates efficiently, minimizing wear on the cutting tools and preventing unscheduled maintenance. Regular CNC Mill Maintenance is Key to Long-Term Success. Proper maintenance is a cornerstone of long-term CNC machine success.High Performance Machine Tool Repair 510-651-6687 45252 Industrial Drive # 32 Fremont, Ca. 94538 Repairs, Preventive Maintenance and performance analysis High Performance CNC Machine Tool Repair. Home. About Us. Testimonials. Quality Statement. Services Provided. Service Discounts. Contact Us. Employment Opportunities. 45252 Industrial Drive .Avoid costly interruptions with CNC machine repair services. CNC repair and CNC drive repair for Fanuc, Rexroth, Mitsubishi and Siemens. Robot Services. Industrial Robotic Sales; . High-speed, Reliable Spindle Motor Repair. Historically, machine tools typically relied on gears or belts to transfer and modify their output, but with today’s .

We conduct CNC machine repairs and maintenance over 80 component brands and more than 25 machine tool manufacturers. We are capable of quickly conducting intensive repairs on virtually any CNC equipment, including servo motors, circuit boards, power supplies, spindle drives, monitors, motor controls, transducers, encoders, and keypads.Our preventative maintenance service technicians are experts at diagnosing problems before they occur. They perform a full CNC machine checkup. Electronics, motors, pumps, hydraulics, lubrication, axis movement, spindle, tool change functions and alignments are all inspected and finely tuned as part of our preventative maintenance service.

In conclusion, CNC machine tool repair is a critical aspect of ensuring the longevity and optimal performance of CNC machines. By understanding the common issues, implementing preventive maintenance measures, and choosing the right repair service, businesses can minimize downtime and maximize productivity. This guide has provided comprehensive .

Therefore, the fault diagnosis of mechanical component and repair security of CNC machine tool has attracted increasing attention of scholars. At home and abroad scholars do a lot of research of CNC machine tool. Maintenance policy has gone through three stages of Corrective maintenance, regular maintenance and state maintenance (Liu Jiang 2007).Start here - Speak to an engineer CNC Repair Services Request a Quote Online Home / At Machine Tool Technologies, we understand just how essential CNC machinery is to businesses. Therefore, any errors or faults can be a major hindrance, not to mention often costly when projects become delayed and tasks fall behind. To combat

preventative maintenance for cnc machines

preventative maintenance. dallas-fort worth cnc repair of most major brands 10 service technicians with over 200 years of experience. our guarantee! we fix it or the labor is free! cnc machine tool troubleshooting & repair. supporting all major brands with fanuc, heidenhain, mitsubishi, mazatrol, osp, fadal, milltronics & haas controls

5 axis cnc milling machine quotes

$2,236.00

cnc machine tool maintenance|cnc machine maintenance checklist pdf