sheet metal paint processing The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In . Extremely thin pieces of sheet metal are designated as “foil” or “leaf”. Pieces thicker than a quarter of an inch are designated as “plate”. Countless everyday objects are constructed from .

0 · sheet metal process

1 · sheet metal finishing process

2 · sheet metal finishing methods

3 · sheet metal fabrication process

Coining dies create the part's shape by squeezing the metal under extreme pressure. Coining also can reduce the metal thickness. Coins (metal currency) are created with the coining process.

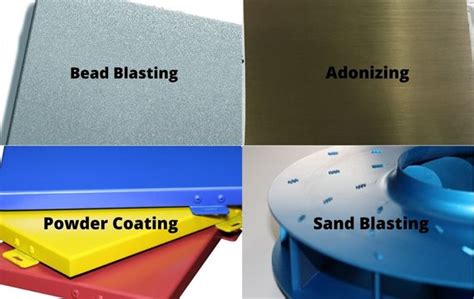

Sheet metal finishing applies protective or decorative coatings to metal parts through chemical, mechanical, or electrical processes. The metal surface undergoes preparation, treatment, and final coating to achieve specific performance and aesthetic goals. Quality finishing directly .

The sheet metal fabrication process is an intricate journey from raw metal to a finished product. It involves various steps, ensuring the final product meets specific standards and functions. In .Sheet metal processing is a method that manipulates flat sheets of metal into desired shapes and structures. Understanding the sheet metal forming process gives us insights into the world of manufacturing, revealing the ingenious . Metal finishing techniques are specifically designed to improve the functional properties of metal surfaces. For example, through a metal finishing process like polishing and grinding, finishes can reduce surface friction .Manufacturers create prepainted steel through a coil coating process. It involves cleaning a metal coil, chemically treating both sides, painting several layers, and curing via an oven. The multilayered painting process includes primer, .

Manufacturers create prepainted steel through a coil coating process. It involves cleaning a metal coil, chemically treating both sides, painting several layers, and curing via an .Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.

To help demystify the different elements of a painted metal finish, to encourage specifiers to select an appropriate color and finish, and to ensure design vision is translated into reality, Steelscape has created this four-part .This guide will explain these processes step by step to help you better understand how sheet metal gets turned into different working metal fabrication parts. The steps for sheet metal .

Pros And Cons Of Spray-Can Paint For Sheet Metal. When it comes to painting sheet metal, using spray-can paint offers some distinct advantages and disadvantages. One of the key advantages is the ease of application, especially on .

Sheet metal stamping is also a process that can be controlled as dimensional changes could be predicted based on die life time studies. The short term capability is very good but the long term looks horible because of die wear. The process variation is fairly small and one of the biggest factors is variation in sheet metal thickness.Sheet Metal Processing Laser Cutting Bending Welding Paint Stamping And Pressing Process. PRODUCT DETAILS 1. Product: OEM Metal Brackets 2. Size: customized as per drawing or sample. 3. Application: Furniture bracket, Fence bracket, Wall bracket, Post bracket, Machinery bracket, Automobile bracket, Building bracket, etc 4. Assembly work supported Confused by sheet metal processing terminology? Our guide offers a comprehensive list of 71 key terms and definitions to help you navigate the world of sheet metal fabrication with confidence. . Spray Paint: Refers to the process of evenly spraying paint on the surface of the workpiece using a specialized spray gun.

Smart Vietnam is a leading sheet metal fabricator in Vietnam, providing a range of services to customers across different industries. Our services include engineering support, laser cutting, punching, forming, folding & bending, welding, powder coating and liquid paint, metal finishing, Hardware & assembly, and quality control & inspection. We work with a variety of materials, .KASRY is a overall solution provider for steel fabrication industry in the world, Kasry specializes in 3D CNC cutting and drilling, welding field with strong capital strength and rich experiences in the industry. About Press Copyright Contact us Creators Advertise Developers Terms Press Copyright Contact us Creators Advertise Developers TermsIf any assembly or post-processing is required, our sheet metal manufacturers will weld, add inserts, or finish the part. . Chem film can be used as a base for paint and can leave surfaces yellow or gold. Adds very little thickness, about 0.00001”-0.00004.” Chem film will conform to MIL-DTL-5541, TYPE I/II.

The integrity of their products should be a given. With prepainted processing, expect low effort and high reward. . From color, shape, texture, type of metal, even paint coat thickness, prepainted steel is made to fit business needs. For example, these options are just for topcoats: polyester, polyurethane, laminate, plastisol, polyvinylidene .ArcelorMittal Sheet Metal Processing is part of the ArcelorMittal Projects business division. We manufacture, source and supply precision fabricated coated parts made from sheet metal. . Our products can be e-coated with powder painting, liquid painted or post galvanised. Watch the video about our processing facility in Egypt .Hengda model is focusing on rapid prototype & CNC machining for 16 years,with 3D measuring instrument and passed ISO9001:2000 quality embodiment certification.Using CNC, 3D printing, Vacuum casting, Sheet Metal and other processes, professional production of various metal, plastic rapid prototypes.Surface finishing: Powder coating. As the final surface treatment we processed sheet metal and structural parts offer powder coating (komaxit). By default, we use epoxy plastic powder (EP) for indoor use, epoxy-polyester powder paint (PEP) for indoor and short-term external environments and polyester powder plastic (PES) for outdoor use with UV resistance.

K.K. Metal Processing Sdn. Bhd. specializes in the flexible manufacturing of precision sheet metal parts since 1974. We have served the banking, laboratory, printing, furniture, air-conditioning, food processing, power technologies, construction, electrical and electronic, water works and many other industries for over 30 years. 3, Sheet metal software. In 3D software, SolidWorks, UG, Pro/E, SolidEdge, TopSolid, CATIA, etc. all of them can be used for custom sheet metal fabrication services, mainly through the editing of 3D graphics to obtain the data required for sheet metal processing (such as unfolded drawings, bending Line, etc.) and provide data for CNC Punching Machine/Laser, .

Sheet metal processing is a comprehensive cold processing technology for metal sheets, which covers a series of technologies such as cutting, stamping, bending, welding, riveting and surface treatment. . Such as electrostatic powder spraying or liquid paint treatment, .Prepainted Steel Processing Services. Prepainted steel is exactly what it sounds like: metal that’s been cleaned, treated, painted, and cured to corrosion-resistant durability. . It’s a continuous process of cleaning, treating, painting, and . In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. .Slide set with metal working laser cutting technology of flat sheet metal steel material processing with sparks authentic shooting in challenging conditions maybe little blurred . Presentation having texture of aluminum oxide sandpaper sheet for final sanding of paint wood metal plastic very fine 220 grit

The paint calculator is intended to estimate the quantity of paint materials when processing pipes, angles, channels, T-beams, I-beams, and sheets. This tool is indispensable for calculating paint for metal per m² of metal and per square meter. Each option differs in its geometry: cross-sectional shape; overall dimensions (diameter);

sheet metal process

The use of fixed molds for sheet metal processing includes blanking molds and forming molds, and is mainly utilized for mass production with a lower cost. 2. Sheet metal processing technology. Blanking: CNC punch, laser cutting, shearing machine; Forming: bending, stretching, hole punching – press brake machine, punch machine, etc Sheet metal processing is a complex and precise operation used in various industries, including automotive, aerospace, and construction. . such as stainless steel or aluminum, especially for outdoor applications. Applying protective coatings like paint, powder coating, or galvanization can also provide a barrier against environmental factors .

Modern sheet metal processing requires comprehensive know-how, especially when it comes to professional sheet metal forming. Since the foundation of the company, IPEK Industries GmbH has developed to a specialist for sheet metal working on the basis of many years of experience and highly qualified employees. . Liquid painting; Equipment. 4 . There are clear instructions you can pursue with the goal that your metal painting work is a fruitful event. Beginning with the correct arrangement for various metals, there are specific strategies for painting various surfaces. . Case study of mass customization of double-curved metal façade panels using a new hybrid sheet metal processing .Painting of sheet metal. Protect your product from external stresses and make it aesthetically pleasing with a coating. Painting industrial manufactured products requires effective, professional methods to achieve a protective, successful result. Powder-coating. Powder-coating is now a common method of industrial painting.

Sheet metal processing covers the entire process from design to finished product, involving many key links such as material selection, process determination, and precision control. This article will deeply explore the common process types and significant advantages of sheet metal processing, helping users make more informed choices when .

It’s all about the quality of the paint — how well it adheres to the metal’s surface, how evenly applied it is, and how it holds up as the steel receives further processing, like being bent or sheared. Prepainted steel requires advanced technology that .Toll processing reflects Steelscape’s ability to paint steel or aluminum material sourced by customers. While not as convenient as a single bill process, Steelscape’s two full-service paint lines are strategically located to be accessible by both rail, truck and ship.

cnc machine small parts

To an oldtimer, a Bell Box or Bell Cover refers to any one, two or three gang weatherproof die cast aluminum box, extension or cover. BELL, founded in 1946 by Frank BELLeck and Harry Stllman, was the first to market weatherproof boxes and covers.

sheet metal paint processing|sheet metal finishing methods