electrical box box clearance hole minimum size The most common screw sizes for electrical boxes are #6-32 and #8-32, with #10-32 screws being used for ground screws as they have a finer thread. The screw diameter should match the mounting holes in the electrical box, with standard electrical box screws having . passive junction. CANopen/DeviceNet Junction Box. Ident. no.: 6603378. Housing material: Nylon; Housing color: black; Protection class IP67; RoHS-compliant; CE compliant; All pins are connected through (1:1) The DeviceNet™ supply voltage between pin 2 and 3 (11 . 30VDC) is displayed via an LED In CANopen this supply voltage is optional .

0 · nec standards for boxes

1 · nec outlet box requirements

2 · nec junction box size limits

3 · nec junction box size calculator

4 · nec junction box dimensions

5 · nec box sizing requirements

6 · junction box sizes

7 · electrical pull box clearance

Slate gray can enhance the aesthetics of a home, especially when paired with soft blue cladding and gray stonework. Corrugated metal roofing is known for its distinctive wavy pattern.

nec standards for boxes

The most common screw sizes for electrical boxes are #6-32 and #8-32, with #10-32 screws being used for ground screws as they have a finer thread. The screw diameter should match the mounting holes in the electrical box, with standard electrical box screws having . Boxes and conduit bodies containing conductors 4 AWG and larger that are required to be insulated must be sized so the conductor insulation . Sounds simple but the box is almost 7 feet wide and 4 feet tall. It also has 28 4" conduits in it. That asside it only has 20 inches of clearance in front. There is a chiller in the .

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For . Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves .

metal fabricator wage ireland

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. I was wondering what the standard electrical wall mounting box used for sockets in america was. I was also wondering what the specifications for these boxes were, as well as, the pitch and size of the screw screw needed for .

Use this box fill calculator to find the correct size of electrical utility box to fit the conducting wires, grounding wires, and devices or equipment you would need to install and have it pass the National Electrical Code®. The National Electrical Code (NEC) specifies the minimum volume of boxes for different numbers and sizes of wires. This is to prevent overheating, short circuits and fire hazards. Using the correct size box also makes it easier .Clearance hole chart for inch bolts and screws. Drill size and hole diameter for normal, close and loose fit classes are tabulated.

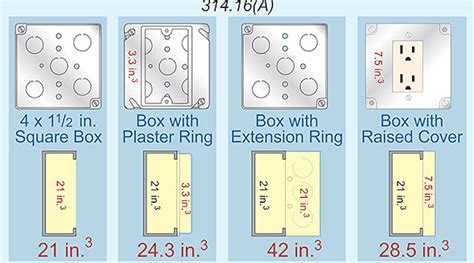

The most common screw sizes for electrical boxes are #6-32 and #8-32, with #10-32 screws being used for ground screws as they have a finer thread. The screw diameter should match the mounting holes in the electrical box, with standard electrical box screws having diameters of #6 (3.5mm) or #8 (4mm). Boxes and conduit bodies containing conductors 4 AWG and larger that are required to be insulated must be sized so the conductor insulation won’t be damaged. The requirements for sizing boxes and conduit bodies containing conductors 6 AWG and smaller are contained in 314.16. Sounds simple but the box is almost 7 feet wide and 4 feet tall. It also has 28 4" conduits in it. That asside it only has 20 inches of clearance in front. There is a chiller in the way. 110.26 says minimum 3 feet. Is there a grandfather rule that anyone knows I . You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. That means the minimum dimensions of boxes and conduit bodies must comply with the following:

Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side.

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. I was wondering what the standard electrical wall mounting box used for sockets in america was. I was also wondering what the specifications for these boxes were, as well as, the pitch and size of the screw screw needed for the for the mounting holes. Use this box fill calculator to find the correct size of electrical utility box to fit the conducting wires, grounding wires, and devices or equipment you would need to install and have it pass the National Electrical Code®. The National Electrical Code (NEC) specifies the minimum volume of boxes for different numbers and sizes of wires. This is to prevent overheating, short circuits and fire hazards. Using the correct size box also makes it easier to connect and secure the wires.

Clearance hole chart for inch bolts and screws. Drill size and hole diameter for normal, close and loose fit classes are tabulated. The most common screw sizes for electrical boxes are #6-32 and #8-32, with #10-32 screws being used for ground screws as they have a finer thread. The screw diameter should match the mounting holes in the electrical box, with standard electrical box screws having diameters of #6 (3.5mm) or #8 (4mm). Boxes and conduit bodies containing conductors 4 AWG and larger that are required to be insulated must be sized so the conductor insulation won’t be damaged. The requirements for sizing boxes and conduit bodies containing conductors 6 AWG and smaller are contained in 314.16.

Sounds simple but the box is almost 7 feet wide and 4 feet tall. It also has 28 4" conduits in it. That asside it only has 20 inches of clearance in front. There is a chiller in the way. 110.26 says minimum 3 feet. Is there a grandfather rule that anyone knows I . You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For conductors 4 AWG and larger, you size pull boxes, junction boxes, and conduit bodies per Sec. 314.28. That means the minimum dimensions of boxes and conduit bodies must comply with the following:

nec outlet box requirements

nec junction box size limits

Use 314.28 (A) to size pull boxes, junction boxes, and conduit bodies when using conductor sizes 4 AWG and larger. Suppose you have a 2-inch raceway coming into a 10-inch square box, and a 2-inch raceway leaves it on the opposite side.

Use this junction box sizing calculator to determine the recommended dimensions of a junction box depending on the number of straight and angle pulls entering it and meet the National Electrical Code®. I was wondering what the standard electrical wall mounting box used for sockets in america was. I was also wondering what the specifications for these boxes were, as well as, the pitch and size of the screw screw needed for the for the mounting holes. Use this box fill calculator to find the correct size of electrical utility box to fit the conducting wires, grounding wires, and devices or equipment you would need to install and have it pass the National Electrical Code®. The National Electrical Code (NEC) specifies the minimum volume of boxes for different numbers and sizes of wires. This is to prevent overheating, short circuits and fire hazards. Using the correct size box also makes it easier to connect and secure the wires.

metal fabricators chattanooga

In a nutshell, the tumbling process is a method for collectively finishing smaller components and workpieces. Depending on the exact technique used, how rough the parts are after fabrication and the number requiring finishing, this mass tumbling process for metals can take anywhere from a few minutes to as long as 24 hours.

electrical box box clearance hole minimum size|nec junction box size calculator