china slitting process in sheet metal This article explores the slitting process in sheet metal manufacturing, covering the basics, material selection, machine configuration, execution of the slit, coil inspection, and packaging and delivery. With the built-in Cooling Fans, internal temperatures can be better maintained. This model is ideal in hot environments. The NB181608-10F includes two .

0 · slitting process in sheet metal

1 · sheet metal slit control

2 · sheet metal shearing process

3 · sheet metal coil slitting process

4 · sheet metal coil shearing process

5 · sheet metal coil cutting

6 · how to slit sheet metal

Sigma's weatherproof closure plugs help keep moisture from the electrical wiring by closing unused holes in weatherproof boxes, extension rings or covers. In a world that runs largely on electricity, junction boxes are crucial to protecting electrical wiring systems.【WATERPROOF SEALING STRIP】- The hinged junction box is sealed with rubber strips to prevent rainwater from entering and protecting internal electrical. The steel electrical box is .

slitting process in sheet metal

Slitting, in the context of sheet metal manufacturing, is a shearing operation that cuts a large roll of material into narrower rolls. The process involves unwinding a large coil of metal and running it through a series of knives before rewinding it to create smaller coils of .This article explores the slitting process in sheet metal manufacturing, covering the .

sheet metal slit control

This article explores the slitting process in sheet metal manufacturing, covering the basics, material selection, machine configuration, execution of the slit, coil inspection, and packaging and delivery.

A slitting line is a processing line designed to take wide metal coils and cut them into narrower strips. This process, known as slitting, is essential for industries that require precise material .

Slitting is a shearing process in which the width of an original, or master, coil is reduced into multiple narrower coils. A wide range of materials and thicknesses can be slit, ranging from .

Slitting is a crucial process in sheet metal fabrication, specifically applied to sheet metal coils. This technique involves cutting a wide coil of sheet metal into narrower strips, contributing to .

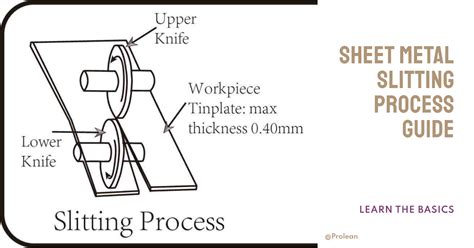

Slitting is a sheet metal cutting process with circular knives, which is used to split wide coiled sheet metal into narrower widths or for edge trimming of rolled sheet. The slitting process is schematically shown in Figure 1.6. Sheet metal slitting machines play a crucial role in maximizing material yield by minimizing scrap and maximizing the utilization of every sheet. Through precise cuts and .

Metal sheet slitting machines are the unsung heroes of the manufacturing realm, tirelessly slicing and dividing sheet metal into uniform strips of varying widths. This meticulous .

sheet metal shearing process

KINGREAL offers Sheet Metal Coil Slitting Machine, which is used to slit and rewind coils of different metal materials according to processing needs. The metal slitting machine mainly consists of decoiler, leveling, feeding, slitting machine, .Laser cutting is a sophisticated slitting process that enables the cutting of metallic and non-metallic raw materials of various material thicknesses. It is a high-precision CNC thermal . Slitting, in the context of sheet metal manufacturing, is a shearing operation that cuts a large roll of material into narrower rolls. The process involves unwinding a large coil of metal and running it through a series of knives before rewinding it to create smaller coils of predetermined width. This article explores the slitting process in sheet metal manufacturing, covering the basics, material selection, machine configuration, execution of the slit, coil inspection, and packaging and delivery.

A slitting line is a processing line designed to take wide metal coils and cut them into narrower strips. This process, known as slitting, is essential for industries that require precise material dimensions for their production needs.Slitting is a shearing process in which the width of an original, or master, coil is reduced into multiple narrower coils. A wide range of materials and thicknesses can be slit, ranging from thin foils to thick plate. Normally, the outside edges of the master coil are trimmed.Slitting is a crucial process in sheet metal fabrication, specifically applied to sheet metal coils. This technique involves cutting a wide coil of sheet metal into narrower strips, contributing to efficient material utilization and the production of multiple narrower coils or sheets.

Slitting is a sheet metal cutting process with circular knives, which is used to split wide coiled sheet metal into narrower widths or for edge trimming of rolled sheet. The slitting process is schematically shown in Figure 1.6.

Sheet metal slitting machines play a crucial role in maximizing material yield by minimizing scrap and maximizing the utilization of every sheet. Through precise cuts and minimal waste, these machines help reduce material costs, .

Metal sheet slitting machines are the unsung heroes of the manufacturing realm, tirelessly slicing and dividing sheet metal into uniform strips of varying widths. This meticulous process plays a pivotal role in industries ranging from automotive and aerospace to packaging and construction.KINGREAL offers Sheet Metal Coil Slitting Machine, which is used to slit and rewind coils of different metal materials according to processing needs. The metal slitting machine mainly consists of decoiler, leveling, feeding, slitting machine, edge trimming and rewinding.Laser cutting is a sophisticated slitting process that enables the cutting of metallic and non-metallic raw materials of various material thicknesses. It is a high-precision CNC thermal process that utilizes a high- power laser beam to precisely cut, melt, or burn a material sheet. Slitting, in the context of sheet metal manufacturing, is a shearing operation that cuts a large roll of material into narrower rolls. The process involves unwinding a large coil of metal and running it through a series of knives before rewinding it to create smaller coils of predetermined width.

This article explores the slitting process in sheet metal manufacturing, covering the basics, material selection, machine configuration, execution of the slit, coil inspection, and packaging and delivery.A slitting line is a processing line designed to take wide metal coils and cut them into narrower strips. This process, known as slitting, is essential for industries that require precise material dimensions for their production needs.

Slitting is a shearing process in which the width of an original, or master, coil is reduced into multiple narrower coils. A wide range of materials and thicknesses can be slit, ranging from thin foils to thick plate. Normally, the outside edges of the master coil are trimmed.Slitting is a crucial process in sheet metal fabrication, specifically applied to sheet metal coils. This technique involves cutting a wide coil of sheet metal into narrower strips, contributing to efficient material utilization and the production of multiple narrower coils or sheets.Slitting is a sheet metal cutting process with circular knives, which is used to split wide coiled sheet metal into narrower widths or for edge trimming of rolled sheet. The slitting process is schematically shown in Figure 1.6. Sheet metal slitting machines play a crucial role in maximizing material yield by minimizing scrap and maximizing the utilization of every sheet. Through precise cuts and minimal waste, these machines help reduce material costs, .

aluminum sheet metal gauge sizes

Metal sheet slitting machines are the unsung heroes of the manufacturing realm, tirelessly slicing and dividing sheet metal into uniform strips of varying widths. This meticulous process plays a pivotal role in industries ranging from automotive and aerospace to packaging and construction.

KINGREAL offers Sheet Metal Coil Slitting Machine, which is used to slit and rewind coils of different metal materials according to processing needs. The metal slitting machine mainly consists of decoiler, leveling, feeding, slitting machine, edge trimming and rewinding.

sheet metal coil slitting process

sheet metal coil shearing process

sheet metal coil cutting

Weather Guard 72 in. x 20.25 in. Textured Matte Black Aluminum Low Profile Crossover Truck Tool Box

china slitting process in sheet metal|sheet metal coil cutting