electrical boxes in fire rated stagger stud walls The rules that govern recessed fixtures in fire-rated walls can basically be broken down into four categories: 1) Steel electrical boxes that do not exceed 16 sq. in., 2) Steel electrical boxes that . Hard part turning is the turning of steel with a hardness over 45 HRc (typically in range 55-68 Hrc). It is more cost effective than grinding. Compared to grinding, it can cut machining time and costs by up to 75 %, and also offers improved flexibility, better lead times.

0 · recessed electrical box fire rated

1 · fire resistant electrical box design

2 · fire rated wall recessed boxes

3 · fire rated wall box protection

4 · fire rated recessed box protection

5 · fire rated electrical boxes requirements

6 · fire rated electrical boxes

7 · fire rated electrical box protection

When you peer out into your front yard, you may have noticed those inconspicuous metal boxes that likely blend into the surroundings. These unassuming structures are known as padmounted transformers, and they play a crucial role in powering your home.

The rules that govern recessed fixtures in fire-rated walls can basically be broken down into four categories: 1) Steel electrical boxes that do not exceed 16 sq. in., 2) Steel electrical boxes that .The guidance covers up to two-hour fire-resistive walls that are either structural (load-bearing) or non-structural (non-load-bearing), and the framing is either wood or steel studs. Walls with a fire-resistive rating greater than two hours will .

Where walls or partitions are required to have a fire-resistance rating, recessed fixtures shall be installed such that the required fire resistance will not be reduced. 4. Boxes other than .

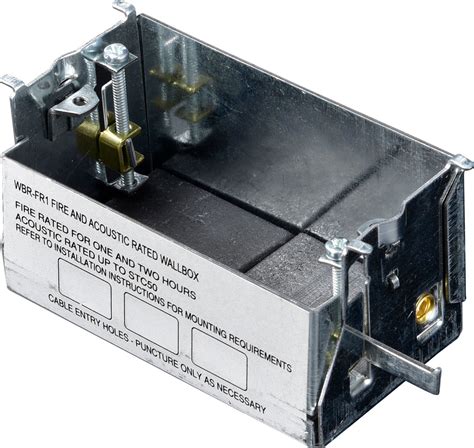

These outlet boxes are intended for installation in bearing and non-load bearing wood or steel stud gypsum wallboard walls with fire resistance ratings of 2 hours or less. The metallic outlet or switch boxes must be securely fastened to the .One way to prevent boxes from reducing the walls fire rating and thus meet the IBC performance requirement is by using putty pads or other listed materials.

Listed single and double gang metallic outlet and switch boxes with metallic or nonmetallic cover plates may be used in bearing and nonbearing wood stud and steel stud . Putty pads are designed to be applied to the external surfaces of metallic and nonmetallic switch and receptacle boxes in some rated wall conditions. We also have used putty pads in a few systems for through .

recessed electrical box fire rated

All recessed fixtures in fire-rated walls and ceilings, and the rules that govern them can basically be broken down into four categories: 1) Steel electrical boxes that do not exceed 16 sq. in., 2) .

Allied Moulded’s fiberglass reinforced polyester (FRP) electrical boxes give you the freedom to make the most of your space, with an exclusive industry fire rating, backed by UL® testing, that bucks the installation limitations found in 2-HR fire .The rules that govern recessed fixtures in fire-rated walls can basically be broken down into four categories: 1) Steel electrical boxes that do not exceed 16 sq. in., 2) Steel electrical boxes that do exceed 16 sq. in., 3) Non-metallic electrical boxes of any size, and 4) Boxes other than electrical boxes Cover plate gaskets Box inserts .

The guidance covers up to two-hour fire-resistive walls that are either structural (load-bearing) or non-structural (non-load-bearing), and the framing is either wood or steel studs. Walls with a fire-resistive rating greater than two hours will require a special study.

UL evaluates both metallic and nonmetallic outlet and switch boxes for use in fire-resistant rated assemblies, and provides guidance for proper installation in the associated product category guide information pages.

fire resistant electrical box design

Where walls or partitions are required to have a fire-resistance rating, recessed fixtures shall be installed such that the required fire resistance will not be reduced. 4. Boxes other than electrical boxes, protected with membrane firestop system having .

These outlet boxes are intended for installation in bearing and non-load bearing wood or steel stud gypsum wallboard walls with fire resistance ratings of 2 hours or less. The metallic outlet or switch boxes must be securely fastened to the studs.One way to prevent boxes from reducing the walls fire rating and thus meet the IBC performance requirement is by using putty pads or other listed materials.

Listed single and double gang metallic outlet and switch boxes with metallic or nonmetallic cover plates may be used in bearing and nonbearing wood stud and steel stud walls with ratings not exceeding 2 h. These walls should have gypsum wallboard facings similar to those shown in Design Nos. U301, U411 and U425. The metallic outlet or switch boxes Putty pads are designed to be applied to the external surfaces of metallic and nonmetallic switch and receptacle boxes in some rated wall conditions. We also have used putty pads in a few systems for through-penetrations.

All recessed fixtures in fire-rated walls and ceilings, and the rules that govern them can basically be broken down into four categories: 1) Steel electrical boxes that do not exceed 16 sq. in., 2) Steel electrical boxes that do exceed 16 sq. in., 3) Non-metallic electrical boxes of any size, and 4) Boxes other than electrical boxes 1.Allied Moulded’s fiberglass reinforced polyester (FRP) electrical boxes give you the freedom to make the most of your space, with an exclusive industry fire rating, backed by UL® testing, that bucks the installation limitations found in 2-HR fire resistive walls.

The rules that govern recessed fixtures in fire-rated walls can basically be broken down into four categories: 1) Steel electrical boxes that do not exceed 16 sq. in., 2) Steel electrical boxes that do exceed 16 sq. in., 3) Non-metallic electrical boxes of any size, and 4) Boxes other than electrical boxes Cover plate gaskets Box inserts .The guidance covers up to two-hour fire-resistive walls that are either structural (load-bearing) or non-structural (non-load-bearing), and the framing is either wood or steel studs. Walls with a fire-resistive rating greater than two hours will require a special study.UL evaluates both metallic and nonmetallic outlet and switch boxes for use in fire-resistant rated assemblies, and provides guidance for proper installation in the associated product category guide information pages.Where walls or partitions are required to have a fire-resistance rating, recessed fixtures shall be installed such that the required fire resistance will not be reduced. 4. Boxes other than electrical boxes, protected with membrane firestop system having .

fire rated wall recessed boxes

These outlet boxes are intended for installation in bearing and non-load bearing wood or steel stud gypsum wallboard walls with fire resistance ratings of 2 hours or less. The metallic outlet or switch boxes must be securely fastened to the studs.One way to prevent boxes from reducing the walls fire rating and thus meet the IBC performance requirement is by using putty pads or other listed materials.

Listed single and double gang metallic outlet and switch boxes with metallic or nonmetallic cover plates may be used in bearing and nonbearing wood stud and steel stud walls with ratings not exceeding 2 h. These walls should have gypsum wallboard facings similar to those shown in Design Nos. U301, U411 and U425. The metallic outlet or switch boxes Putty pads are designed to be applied to the external surfaces of metallic and nonmetallic switch and receptacle boxes in some rated wall conditions. We also have used putty pads in a few systems for through-penetrations.All recessed fixtures in fire-rated walls and ceilings, and the rules that govern them can basically be broken down into four categories: 1) Steel electrical boxes that do not exceed 16 sq. in., 2) Steel electrical boxes that do exceed 16 sq. in., 3) Non-metallic electrical boxes of any size, and 4) Boxes other than electrical boxes 1.

electrical panel box solar

electrical project boxes uk

Unused openings for circuit breakers and switches shall be closed using identified closures, or other approved means that provide protection substantially equivalent to the wall .

electrical boxes in fire rated stagger stud walls|fire resistant electrical box design