battery junction box function The main function of the battery management system (BMS) is to monitor cell voltage, battery pack voltage and battery pack current. In addition, given the high voltage design of the BMS, it is necessary to measure the . Had a carpenter over today (redoing kitchen) and he said there's now a way to enclose a junction box behind a wall. I want to close off some outlets behind cabinets and I said we'll have to cut an access panel in the .

0 · physical location of battery junction

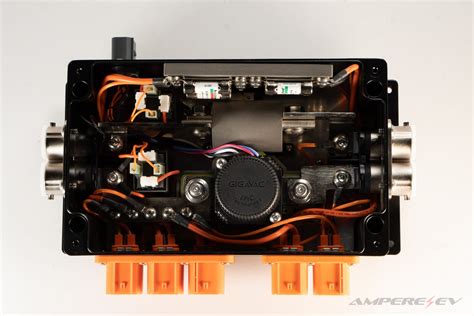

1 · junction box in electrical vehicle

2 · high voltage junction box automotive

3 · high voltage battery junction box

4 · high current battery junction box

5 · battery terminal junction block

6 · battery junction box ford f350

7 · 2022 f350 battery junction box

Junction Boxes Strong, Durable, Maintenance-Free Junction Boxes. Smith-Midland’s utility products set the industry standard for excellence. Our junction boxes offer a wide range of sizes and details for a variety of uses: Hand Holes; Drainage and Sump Boxes; Splice Boxes; Meter and Valve Boxes; Distribution Boxes; Traffic Signal Control Boxes

functions within the battery pack. The traditional BJB is a relay box or a switch box with power contactors that connects the entire battery pack to the load inverter, motor or the battery charger.How to design an intelligent battery junction box for advanced EV battery manageme .How to Design an Intelligent Battery Junction Box for Advanced EV Battery . The main function of a battery management system (BMS) is to monitor cell voltages, pack voltages, and pack current. In addition, due to the high-voltage design of the BMS, insulation resistance measurement between .

The main function of the battery management system (BMS) is to monitor cell voltage, battery pack voltage and battery pack current. In addition, given the high voltage design of the BMS, it is necessary to measure the . Learn how a novel electric vehicle (EV) capacitive-isolation daisy-chain data acquisition IC enables a streamlined junction box time-aligned with battery cell voltage and . NXP recently rolled out a battery junction box IC that combines critical pack-level monitoring functions in a single chip. According to the company, it delivers faster, safer, and .How to design an intelligent battery junction box for advanced EV battery manageme Effective voltage and current synchronization enables precise state-of-health, state-of-charge and .

The battery junction box (BJB) is the controlling part of the BMS. It measures several high-voltages throughout the overal BMS, accurately and redundantly measures the system's current and measures isolation resistance between the .How to Design an Intelligent Battery Junction Box for Advanced EV Battery Management Systems Each battery cell voltage is monitored by control modules and appropriate control methods are applied to keep voltage deltas between cells to a tight tolerance. The junction box controls the high-voltage connections for the .

functions within the battery pack. The traditional BJB is a relay box or a switch box with power contactors that connects the entire battery pack to the load inverter, motor or the battery charger. The main function of a battery management system (BMS) is to monitor cell voltages, pack voltages, and pack current. In addition, due to the high-voltage design of the BMS, insulation resistance measurement between the high-voltage and low-voltage domains is needed to catch defects in the battery structure and protect against hazardous conditions. The main function of the battery management system (BMS) is to monitor cell voltage, battery pack voltage and battery pack current. In addition, given the high voltage design of the BMS, it is necessary to measure the insulation resistance between the high and low voltage domains to catch defects in the cell structure and prevent dangerous .

Learn how a novel electric vehicle (EV) capacitive-isolation daisy-chain data acquisition IC enables a streamlined junction box time-aligned with battery cell voltage and temperature measurements. NXP recently rolled out a battery junction box IC that combines critical pack-level monitoring functions in a single chip. According to the company, it delivers faster, safer, and more.How to design an intelligent battery junction box for advanced EV battery manageme Effective voltage and current synchronization enables precise state-of-health, state-of-charge and electrical impedance spectroscopy calculations that will result in optimal utilization of the EV battery.The battery junction box (BJB) is the controlling part of the BMS. It measures several high-voltages throughout the overal BMS, accurately and redundantly measures the system's current and measures isolation resistance between the battery and the chassis for isolation monitoring.

physical location of battery junction

How to Design an Intelligent Battery Junction Box for Advanced EV Battery Management Systems Each battery cell voltage is monitored by control modules and appropriate control methods are applied to keep voltage deltas between cells to a tight tolerance. The junction box controls the high-voltage connections for the charging system, inverter/motor, and battery pack. Consolidating essential battery management system (BMS) functions in a single chip simplifies the design and development of junction boxes for EVs such as those developed by Volkswagen. This helps protect high-voltage batteries from overcurrent by constantly monitoring the battery current and slope every eight microseconds.functions within the battery pack. The traditional BJB is a relay box or a switch box with power contactors that connects the entire battery pack to the load inverter, motor or the battery charger.

The main function of a battery management system (BMS) is to monitor cell voltages, pack voltages, and pack current. In addition, due to the high-voltage design of the BMS, insulation resistance measurement between the high-voltage and low-voltage domains is needed to catch defects in the battery structure and protect against hazardous conditions.

The main function of the battery management system (BMS) is to monitor cell voltage, battery pack voltage and battery pack current. In addition, given the high voltage design of the BMS, it is necessary to measure the insulation resistance between the high and low voltage domains to catch defects in the cell structure and prevent dangerous .

Learn how a novel electric vehicle (EV) capacitive-isolation daisy-chain data acquisition IC enables a streamlined junction box time-aligned with battery cell voltage and temperature measurements. NXP recently rolled out a battery junction box IC that combines critical pack-level monitoring functions in a single chip. According to the company, it delivers faster, safer, and more.

How to design an intelligent battery junction box for advanced EV battery manageme Effective voltage and current synchronization enables precise state-of-health, state-of-charge and electrical impedance spectroscopy calculations that will result in optimal utilization of the EV battery.The battery junction box (BJB) is the controlling part of the BMS. It measures several high-voltages throughout the overal BMS, accurately and redundantly measures the system's current and measures isolation resistance between the battery and the chassis for isolation monitoring.

How to Design an Intelligent Battery Junction Box for Advanced EV Battery Management Systems

Each battery cell voltage is monitored by control modules and appropriate control methods are applied to keep voltage deltas between cells to a tight tolerance. The junction box controls the high-voltage connections for the charging system, inverter/motor, and battery pack.

mecanizado en cnc

junction box in electrical vehicle

$321.70

battery junction box function|physical location of battery junction