butt welding sheet metal stud welder Butt welding sheet metal is a fundamental welding technique that involves joining two metal sheets end-to-end. This process creates a strong and durable weld, making it an essential skill for fabricators and welders across . Zero Skateboards is a skateboard company located in Carlsbad, California, United States. The brand was founded by professional skateboarder and entrepreneur Jamie Thomas, and distributed by his Black Box Distribution company. In late June 2014, Thomas announced that the brand would be distributed by the Dwindle Distribution company, based in El Segundo, California. .

0 · how to butt weld sheet metal

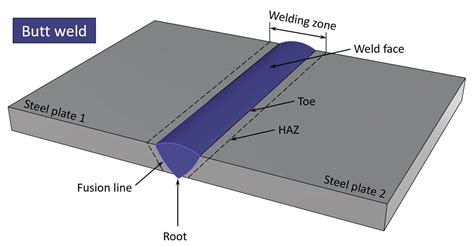

1 · butt welding structure

2 · butt welding steel

3 · butt welding design

4 · butt weld material

5 · butt weld example

6 · butt joint preparation

7 · butt joint in welding

Don't ground to the electrical box. Connecting the ground wire to a metal electrical box will energize the box in the event of a short circuit. The box could overheat and start a fire, or someone could get a shock from touching it.

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt. Butt welding sheet metal is a fundamental welding technique that involves joining two metal sheets end-to-end. This process creates a strong and durable weld, making it an essential skill for fabricators and welders across . A butt weld is a welding technique where two metal pieces are joined together along their edges in a single plane. This creates a strong and seamless bond, commonly used in the construction, manufacturing, and . Butt welds are a popular welding technique used in metal fabrication. They join two pieces of metal by heating and pressing the edges together, creating a strong bond. Different types of butt welds include gas .

Butt welds can be used when welding both thin sheet metal and thick metal, but there are specific steps in weld preparation. The thickness of the metal pieces will indicate whether the butt joints are square or beveled.Butt welding sheet metal is a very important skill to develop for replacing sheet metal in your restoration. Joint preparation and welder setup are the keys to a successful job. In the above .

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt. Butt welding sheet metal is a fundamental welding technique that involves joining two metal sheets end-to-end. This process creates a strong and durable weld, making it an essential skill for fabricators and welders across various industries.

The following are the main welding processes used for Sheet Metal welding: Stick Welding or SMAW; Gas Tungsten Arc Welding (GTAW or TIG) A butt weld is a welding technique where two metal pieces are joined together along their edges in a single plane. This creates a strong and seamless bond, commonly used in the construction, manufacturing, and automotive industries for its reliability and structural strength. Butt welds are a popular welding technique used in metal fabrication. They join two pieces of metal by heating and pressing the edges together, creating a strong bond. Different types of butt welds include gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW).

Butt welds can be used when welding both thin sheet metal and thick metal, but there are specific steps in weld preparation. The thickness of the metal pieces will indicate whether the butt joints are square or beveled.Butt welding sheet metal is a very important skill to develop for replacing sheet metal in your restoration. Joint preparation and welder setup are the keys to a successful job. In the above video tips are given for the actual welding process as well as some setup information.Butt welding is a fusion welding technique used to join two pieces of metal along a single plane. It involves bringing the edges of the two workpieces together and then melting and fusing them to create a strong and continuous joint.

Discover the art of butt welding with our detailed guide. Learn various methods, techniques, and tips to perfect your welding skills. Ideal for beginners and pros alike. A butt weld consists of two pieces of metal placed next to each other “end-to-end” in the same plane. Applying a continuous weld down the centerline welds the pieces together. There is no stock overlap, and the joint can have a root opening.

Today we're going to demonstrate how to butt weld sheet metal using a Lincoln Electric mig welder. Like anything, there's a right way and a wrong way to butt.

Butt welding sheet metal is a fundamental welding technique that involves joining two metal sheets end-to-end. This process creates a strong and durable weld, making it an essential skill for fabricators and welders across various industries. The following are the main welding processes used for Sheet Metal welding: Stick Welding or SMAW; Gas Tungsten Arc Welding (GTAW or TIG) A butt weld is a welding technique where two metal pieces are joined together along their edges in a single plane. This creates a strong and seamless bond, commonly used in the construction, manufacturing, and automotive industries for its reliability and structural strength.

how to butt weld sheet metal

Butt welds are a popular welding technique used in metal fabrication. They join two pieces of metal by heating and pressing the edges together, creating a strong bond. Different types of butt welds include gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and shielded metal arc welding (SMAW).

Butt welds can be used when welding both thin sheet metal and thick metal, but there are specific steps in weld preparation. The thickness of the metal pieces will indicate whether the butt joints are square or beveled.Butt welding sheet metal is a very important skill to develop for replacing sheet metal in your restoration. Joint preparation and welder setup are the keys to a successful job. In the above video tips are given for the actual welding process as well as some setup information.Butt welding is a fusion welding technique used to join two pieces of metal along a single plane. It involves bringing the edges of the two workpieces together and then melting and fusing them to create a strong and continuous joint.

Discover the art of butt welding with our detailed guide. Learn various methods, techniques, and tips to perfect your welding skills. Ideal for beginners and pros alike.

butt welding structure

After researching I remember 18 gauge was the choice thickness, is this correct? I called one of the local metal warehouses and they said they only carry 18ga in cold rolled. Do I need cold rolled or hot rolled? Does it matter? I was quoted about $120 for a 4x8 sheet does this sound right? Thanks. I am a body work noob.

butt welding sheet metal stud welder|how to butt weld sheet metal