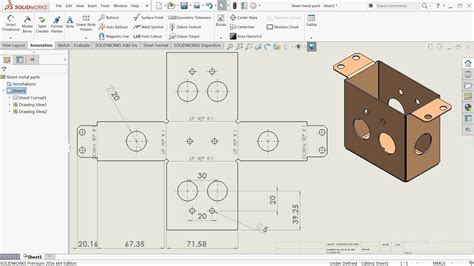

dimensioning sheet metal A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best . V (also known as V: The Series) is an American science fiction television series that aired in the United States on NBC from October 26, 1984, to March 22, 1985. It is a continuation of the V franchise about an alien invasion of Earth by a carnivorous race of reptilians known as "Visitors", which was originally conceived by American writer, producer, and director Kenneth Johnson.

0 · simple sheet metal drawings

1 · sheet metal part drawing

2 · sheet metal layout drawings

3 · sheet metal drawing symbols

4 · sheet metal drawing dimensioning

5 · sheet metal dimensioning standards

6 · sheet metal dimensioning guidelines

7 · sheet metal detail drawing

When making electrical repairs, you can use a plastic electrical or junction box or a metal box. Learn when to use a plastic box vs. metal box.

Some critical dimensions that need to be considered when setting up sheet metal in CAD software are sheet metal thickness, the k-factor, and bend radius. One needs to check that these factors are consistent with the tooling that will be .A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best .Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a .Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost.

Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this . Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, .

Part sketches should be dimensioned and constrained in a manner that allows them to be easily modified without deforming the part and causing rebuild errors. Design intent . Sheet metal detail drawings developed using CAD tools like SolidWorks, Inventor®, SolidEdge, Creo etc. abide by design rules and enable seamless collaboration. They also address the need for standard methods of .

cnc lathe machining turning free sample

In CAD drafting for sheet metal fabrication, dimensioning involves precisely annotating the size and location of features on 2D drawings or 3D models, crucial for part fit and function. This .Dimension the part in a single direction wherever possible. Because of the sequential nature of the forming process, and the fact that dimensional variation is introduced at each bend, dimensioning in a single direction parallels the process and helps to .Some critical dimensions that need to be considered when setting up sheet metal in CAD software are sheet metal thickness, the k-factor, and bend radius. One needs to check that these factors are consistent with the tooling that will be used in manufacturing.A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best practice to dimension to virtual intersection points and show included bend angles.

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost. Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this information requires a series of . Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, dimensions, material, surface treatments, allowable tolerances, and other pertinent information.

Part sketches should be dimensioned and constrained in a manner that allows them to be easily modified without deforming the part and causing rebuild errors. Design intent should be considered when creating part sketches.

Sheet metal detail drawings developed using CAD tools like SolidWorks, Inventor®, SolidEdge, Creo etc. abide by design rules and enable seamless collaboration. They also address the need for standard methods of dimensioning by following the rules of region-specific and universal drafting practices. 1. Need for detailing as per design consideration.

In CAD drafting for sheet metal fabrication, dimensioning involves precisely annotating the size and location of features on 2D drawings or 3D models, crucial for part fit and function. This includes specifying all necessary measurements like length, width, depth, and radius to match the physical component sizes.Dimension the part in a single direction wherever possible. Because of the sequential nature of the forming process, and the fact that dimensional variation is introduced at each bend, dimensioning in a single direction parallels the process and helps to .Some critical dimensions that need to be considered when setting up sheet metal in CAD software are sheet metal thickness, the k-factor, and bend radius. One needs to check that these factors are consistent with the tooling that will be used in manufacturing.A fully dimensioned sheet metal drawing includes dimensions for all bends, holes, countersinks, flanges, and other formed features (such as hems and curls, ribs, dimples, etc.). It is a best practice to dimension to virtual intersection points and show included bend angles.

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and bending. 3D CAD files are converted into machine code, which controls a machine to precisely cut a flat pattern, which can be formed .

Sheet metal design guidelines are followed for sheet metal enclosure and part design to ensure the first time right product and reduce cost. Reading a sheet metal drawing involves identifying the details of the design of sheet metal parts, such as dimensions, geometry, material specifications, and any special requirements. Meanwhile, detailing this information requires a series of . Sheet metal drawings are a type of mechanical drawing primarily used to depict the details and dimensional specifications of sheet metal fabrication parts. They provide detailed descriptions of the part’s shape, dimensions, material, surface treatments, allowable tolerances, and other pertinent information.

Part sketches should be dimensioned and constrained in a manner that allows them to be easily modified without deforming the part and causing rebuild errors. Design intent should be considered when creating part sketches.

Sheet metal detail drawings developed using CAD tools like SolidWorks, Inventor®, SolidEdge, Creo etc. abide by design rules and enable seamless collaboration. They also address the need for standard methods of dimensioning by following the rules of region-specific and universal drafting practices. 1. Need for detailing as per design consideration.

simple sheet metal drawings

Metal boxes, especially with romex, are a PITA: more sharp edges, more time to make up, clamps in box etc. The contractor wanted me to talk directly to the H.O. about it so I thought I would see what possible reasons you guys come up with to use and not to use them.

dimensioning sheet metal|simple sheet metal drawings