bent sheet metal Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes. $9,950.00

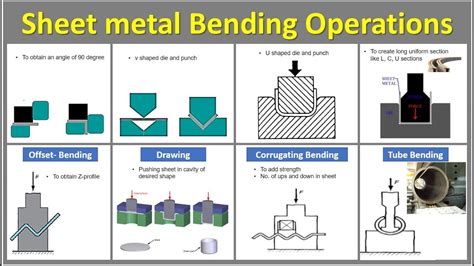

0 · types of sheet metal bends

1 · types of sheet metal benders

2 · sheet metal cutting and bending

3 · sheet metal bending design guide

4 · sheet metal bending basics

5 · maximum thickness sheet metal bending

6 · bending tool for sheet metal

7 · bendable sheet metal

Master Aircraft Mechanic Tool Box 4X. Get nearly all the aircraft sheet metal tools you'll need in this kit: rivet gun, hole finders, clecos, clamps, drills, and dozens more. All at a savings only a Yardstore sheet metal tool kit can deliver. Includes: 1 Riveter Acat 4X (12003) 1 Texas Palm Drill, 2600 RPM (12675) 1 ACAT 90° Drill SDM (12111)

types of sheet metal bends

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See moreThis guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts. Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes.

Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final .Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make .

metal machined enclosure

No matter the material, its gauge or thickness, mild steels and soft aluminums are much more ductile than high-strength materials and, therefore, can be bent to a sharper radius. That’s why when bending thick or high-tensile . From basic concepts to advanced techniques, this guide covers everything you need to know about sheet metal bending. Learn about the different bending methods, tools, and tips to achieve accurate and high-quality results.

Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the .In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts. Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. This is done through the application of force on a workpiece. Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes. Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final shape.

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.

No matter the material, its gauge or thickness, mild steels and soft aluminums are much more ductile than high-strength materials and, therefore, can be bent to a sharper radius. That’s why when bending thick or high-tensile metals, you need to abide by a . From basic concepts to advanced techniques, this guide covers everything you need to know about sheet metal bending. Learn about the different bending methods, tools, and tips to achieve accurate and high-quality results. Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the final geometry. The thickness of sheet metal used can vary.In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts. Bending is one of the most common sheet metal fabrication operations. Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. This is done through the application of force on a workpiece.

Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes. Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final shape.

types of sheet metal benders

sheet metal cutting and bending

Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.

No matter the material, its gauge or thickness, mild steels and soft aluminums are much more ductile than high-strength materials and, therefore, can be bent to a sharper radius. That’s why when bending thick or high-tensile metals, you need to abide by a . From basic concepts to advanced techniques, this guide covers everything you need to know about sheet metal bending. Learn about the different bending methods, tools, and tips to achieve accurate and high-quality results. Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the final geometry. The thickness of sheet metal used can vary.

metal manufacturing cnc machine coolant hd wide

Amazon.com: UrbHome 3 inch Wall Bracket L Shape Metal Shelf Support, Pack of 8, Color White, (5x6) : Tools & Home Improvement

bent sheet metal|bending tool for sheet metal