bend relief sheet metal In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced techniques and real-world applications that contribute to successful fabrication endeavors. Pioneer Plastics - Archival Plastic Display & Storage Supplies. Hollinger Metal Edge - Archival Storage Supplies. Archival Methods - Archival & Photo Preservation & Display Supplies. BRODART - Library, Museum, and Archive Supplies PrintFile - Archival Storage (THEY HAVE 2.5x3.5 FOR CDV'S) B&H Photo Video Audio - Archival Storage SectionThe door that connects your house and garage is called a garage entry door. These doors must be fire-rated doors, made of specific materials in order to ensure they meet fire safety standards. These doors must pass all .

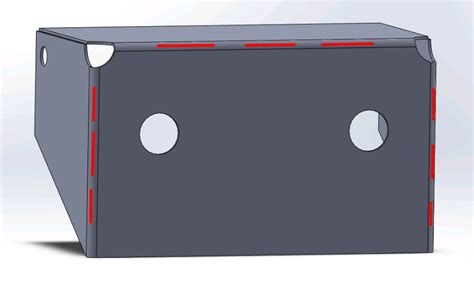

0 · solidworks sheet metal relief cut

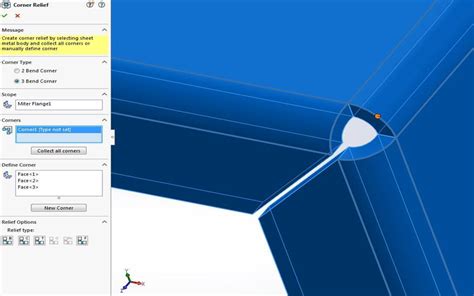

1 · solidworks sheet metal corner relief

2 · solidworks sheet metal bend relief

3 · sheet metal fabrication design guide

4 · sheet metal corner relief chart

5 · sheet metal bending chart

6 · sheet metal bend relief guidelines

7 · auto relief solidworks sheet metal

The smaller oblong knockouts in the corners of the box have NM clamps integral with the box - no additional clamp is needed. The integral clamp is a metal clip riveted to the box that the NM cable passes under when you shove it through the knockout.

A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. They are a .Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Recommended Bend Relief height is always more than two times of .Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part. Figure "B" shows a part with the edge a sufficient distance . Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Although they are small features, leaving .

In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced techniques and real-world applications that contribute to successful fabrication endeavors. Learn how to design sheet metal parts with bend relief, small holes, hole distortion, and minimum flange widths. The article explains the benefits and constraints of different bending methods and materials. Bend reliefs prevent tears during transitions between bends or between a bend and a flat surface. They ensure a clean part free from deformation, burrs, and sharp points, especially crucial for parts subject to .CUT/BEND RELIEF DESIGN TIPS • To ensure cost-effective production, design cut and bend reliefs with a minimum of 2.5x material thickness. • For prototype and short-run quantities, the .

A bend relief creates space between the bent and unbent surfaces so that the edge of the sheet metal is perpendicular to the bend itself. The gap between the bend and surrounding material allows us to shape the sheet in . See how and when specifically to design bend reliefs and corner reliefs in sheet metal parts to open up geometry options & tighter tolerances A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. They are a great way to ensure a clean looking part that is free from deformation, burrs, and sharp points where the bend edges terminate.Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Recommended Bend Relief height is always more than two times of sheet thickness plus bend radius. Creating an extruded hole .

solidworks sheet metal relief cut

Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part. Figure "B" shows a part with the edge a sufficient distance from the form. This distance should never be less than the radius of the bend.

Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Although they are small features, leaving them out can cause stress to concentrate at the bend line, resulting in deformed holes and slots. In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced techniques and real-world applications that contribute to successful fabrication endeavors.

The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether you are coining or air bending on a press brake, and adding bend relief to prevent tearing material. Bend reliefs prevent tears during transitions between bends or between a bend and a flat surface. They ensure a clean part free from deformation, burrs, and sharp points, especially crucial for parts subject to vibration or flexion.CUT/BEND RELIEF DESIGN TIPS • To ensure cost-effective production, design cut and bend reliefs with a minimum of 2.5x material thickness. • For prototype and short-run quantities, the minimum cut relief can be a laser or water jet cut kerf (0.010” - 0.040”). • Lanced (sheared) features with zero cut relief are possible but A bend relief creates space between the bent and unbent surfaces so that the edge of the sheet metal is perpendicular to the bend itself. The gap between the bend and surrounding material allows us to shape the sheet in the press brake cleanly, eliminating cracking and tearing.

solidworks sheet metal corner relief

See how and when specifically to design bend reliefs and corner reliefs in sheet metal parts to open up geometry options & tighter tolerances

A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. They are a great way to ensure a clean looking part that is free from deformation, burrs, and sharp points where the bend edges terminate.Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Recommended Bend Relief height is always more than two times of sheet thickness plus bend radius. Creating an extruded hole .

how to turn campsite electric box into outlet

Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part. Figure "B" shows a part with the edge a sufficient distance from the form. This distance should never be less than the radius of the bend.Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Although they are small features, leaving them out can cause stress to concentrate at the bend line, resulting in deformed holes and slots.

In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced techniques and real-world applications that contribute to successful fabrication endeavors. The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether you are coining or air bending on a press brake, and adding bend relief to prevent tearing material. Bend reliefs prevent tears during transitions between bends or between a bend and a flat surface. They ensure a clean part free from deformation, burrs, and sharp points, especially crucial for parts subject to vibration or flexion.

CUT/BEND RELIEF DESIGN TIPS • To ensure cost-effective production, design cut and bend reliefs with a minimum of 2.5x material thickness. • For prototype and short-run quantities, the minimum cut relief can be a laser or water jet cut kerf (0.010” - 0.040”). • Lanced (sheared) features with zero cut relief are possible but

solidworks sheet metal bend relief

sheet metal fabrication design guide

sheet metal corner relief chart

sheet metal bending chart

Solid shutters provided more insulation and were able to prevent insects from entering the home. In medieval Europe, houses had rectangular windows with solid shutters that sometimes .

bend relief sheet metal|solidworks sheet metal relief cut