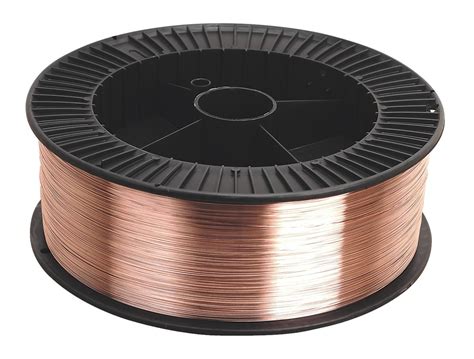

best mig wire for automotive sheet metal $68.88 When it comes to insulation for metal roofs, there are a large number of options available. We'll look at a few of the most common in this post. Fiberglass batt insulation is one of the more popular types for roofing. It’s relatively inexpensive and available in a wide variety of different R-values.

0 · mild steel mig welding wire

1 · mig wire types chart

2 · mig welding wire size selection

3 · mig welding wire size explained

4 · high tensile strength mig wire

5 · esab welding wire chart

6 · choosing mig wire size

7 · 023 welding wire

An electrical junction box (also known as a "jbox") is an enclosure housing electrical connections. [1] Junction boxes protect the electrical connections from the weather, as well as protecting people from accidental electric shocks.

mild steel mig welding wire

Users share their experiences and opinions on choosing mig wire for welding auto body sheet metal. They compare different sizes, types and brands of wire, and give tips on technique and settings. If you MUST mig it, a soft 023 wire like the old Lincoln Easygrind would work. but the very best bet is TIG welding butt jointed patches and planishing. or if you have the skill .

If you plan to tackle thin sheet metal applications, you should opt for a .023 wire diameter, while .030 is just fine for thicker stock and farm implement fabrication. Overall, this .

3d printed parts on cnc plasma

.99.88.10.79

.17.39 Never go for a thinner base metal for auto body sheet welding to get the best result out of it. When starting to learn auto body sheet metal welding with a MIG welder, you should opt for a shielding gas that has a higher . In this blog post, we will explore the key factors that affect MIG welding sheet metal, including wire size, gas selection, amperage, and voltage. We will also provide tips and best practices to help you achieve optimal .

Every welder has their own preferences for sheet metal. I’m using 0.023-inch ER 70 S-6 filler wire and 15 cfh (cubic feet per hour) of C-25 shielding gas with my Millermatic® 211 MIG welder. After the first tacks are in place, the . The best size MIG wire for car panels depends on the thickness of the panels. Thinner panels usually require smaller wire sizes, such as 0.023-inch or 0.030-inch wire, while thicker panels may require larger wire sizes, such as .

Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still .

Just ordered a Hobart 140 and need to choose solid wire. I have an 80cf bottle being hydro'd, revalved and filled with ArCo2 75-25. Which wire should I be running for mainly auto body sheet metal? I plan on trying .023, not sure if it should be ER70s 2, 3 or 6. Thanks! Lincoln AC/DC 225/125 and WP17. 75A AC is for pipe thawing!

If you MUST mig it, a soft 023 wire like the old Lincoln Easygrind would work. but the very best bet is TIG welding butt jointed patches and planishing. or if you have the skill and patience. oxy fuel butt welds. hammerwelded and planished... For filler metal selection, the electrodes in the ER4xxx and ER5xxx are most suitable for welding auto body panels. The panels’ aluminum’s chemical properties also require high voltage and wire feed speed settings to match the appropriate mode of metal transfer. If you plan to tackle thin sheet metal applications, you should opt for a .023 wire diameter, while .030 is just fine for thicker stock and farm implement fabrication. Overall, this might be one of the best MIG wires, but it is certainly one of the most popular choices. What is the best Mig wire for automotive sheet metal? .023 Mig wire is the best choice for automotive sheet metal. They ensure a decent weld penetration with no chance of burning through.

Never go for a thinner base metal for auto body sheet welding to get the best result out of it. When starting to learn auto body sheet metal welding with a MIG welder, you should opt for a shielding gas that has a higher proportion of argon gas. In this blog post, we will explore the key factors that affect MIG welding sheet metal, including wire size, gas selection, amperage, and voltage. We will also provide tips and best practices to help you achieve optimal welding results. Every welder has their own preferences for sheet metal. I’m using 0.023-inch ER 70 S-6 filler wire and 15 cfh (cubic feet per hour) of C-25 shielding gas with my Millermatic® 211 MIG welder. After the first tacks are in place, the clamps are removed.

The best size MIG wire for car panels depends on the thickness of the panels. Thinner panels usually require smaller wire sizes, such as 0.023-inch or 0.030-inch wire, while thicker panels may require larger wire sizes, such as 0.035-inch or 0.045-inch wire. Learn why MIG, pulsed MIG, TIG and pulsed TIG are the ideal choices when welding sheet metal. When welding thin metal, the main objective is to avoid warping, burn-through and excessive heat-affected zones while still ensuring the weld has enough mechanical strength for the application.

Just ordered a Hobart 140 and need to choose solid wire. I have an 80cf bottle being hydro'd, revalved and filled with ArCo2 75-25. Which wire should I be running for mainly auto body sheet metal? I plan on trying .023, not sure if it should be ER70s 2, 3 or 6. Thanks! Lincoln AC/DC 225/125 and WP17. 75A AC is for pipe thawing! If you MUST mig it, a soft 023 wire like the old Lincoln Easygrind would work. but the very best bet is TIG welding butt jointed patches and planishing. or if you have the skill and patience. oxy fuel butt welds. hammerwelded and planished...

For filler metal selection, the electrodes in the ER4xxx and ER5xxx are most suitable for welding auto body panels. The panels’ aluminum’s chemical properties also require high voltage and wire feed speed settings to match the appropriate mode of metal transfer. If you plan to tackle thin sheet metal applications, you should opt for a .023 wire diameter, while .030 is just fine for thicker stock and farm implement fabrication. Overall, this might be one of the best MIG wires, but it is certainly one of the most popular choices.

What is the best Mig wire for automotive sheet metal? .023 Mig wire is the best choice for automotive sheet metal. They ensure a decent weld penetration with no chance of burning through.

Never go for a thinner base metal for auto body sheet welding to get the best result out of it. When starting to learn auto body sheet metal welding with a MIG welder, you should opt for a shielding gas that has a higher proportion of argon gas. In this blog post, we will explore the key factors that affect MIG welding sheet metal, including wire size, gas selection, amperage, and voltage. We will also provide tips and best practices to help you achieve optimal welding results. Every welder has their own preferences for sheet metal. I’m using 0.023-inch ER 70 S-6 filler wire and 15 cfh (cubic feet per hour) of C-25 shielding gas with my Millermatic® 211 MIG welder. After the first tacks are in place, the clamps are removed. The best size MIG wire for car panels depends on the thickness of the panels. Thinner panels usually require smaller wire sizes, such as 0.023-inch or 0.030-inch wire, while thicker panels may require larger wire sizes, such as 0.035-inch or 0.045-inch wire.

3d model cnc milling machine

LOCATOR components enables the patient to easily seat the prosthesis. The LOCATOR attachment is designed to require minimum of vertical space, while overcoming implant divergence of up to 40° between two implants.

best mig wire for automotive sheet metal|esab welding wire chart