what is sheet metal bending Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum. Delving deeper, we encounter diverse laser cutting machines, each with its unique properties and applications. These powerful machines, the fiber laser cutters, don’t merely boast of their prowess without reason.

0 · types of sheet metal benders

1 · types of bending sheet metal

2 · sheet metal bending guidelines

3 · sheet metal bending guide

4 · sheet metal bending dies

5 · sheet metal bending design guide

6 · sheet metal bending basics

7 · maximum thickness sheet metal bending

$9.99

types of sheet metal benders

Sheet metal bending refers to deforming the flat metal sheet into a specific angle or curvature. It does not change the thickness of the sheet. Instead, the plastic (permanent) deformation is responsible for the formation of the final .

What is Sheet Metal Bending? CNC sheet metal bending is one of the most underrated processes available for sheet metal part production. With bending, it’s possible to produce a wide variety . Sheet metal bending calculation basics. Calculating bend allowance, outside setback, and bend deductions. By Steve Benson. Updated May 18, 2023. November 9, 2012. Article. Bending and Forming. Figure 1: The . Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

metal fabrication company definition

types of bending sheet metal

Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the .

Improve your sheet metal bending techniques with these 8 design guidelines. Learn how to create precise bends and avoid costly mistakes. Sheet metal bending refers to the fundamental process in metalworking that involves taking flat metal sheets and shaping them into three-dimensional items by applying force. Sheet metal bending is common .Sheet metal bending is a manufacturing process where a force is applied to a piece of sheet metal, causing it to bend at an angle and form a desired shape. It’s about precision, skill, and understanding the material you’re working with. The .Discover the fundamentals of sheet metal bending, including its definition, types, and practical tips for efficient metal shaping.

Bending sheet metal without a brake is a technique used when a brake is not available. Basic principles include marking the metal, securing it with clamps or vices, and applying even pressure using improvised tools like pliers or a .

Sheet metal fabrication is the process of forming metal sheets to the desired shape using different manufacturing methods. The completion of a product usually comprises of many steps – from cutting and bending to .Sheet metal fabrication is a multifaceted manufacturing process that involves the shaping, cutting, and assembling of metal sheets to create a wide range of custom components. This process is essential for numerous industries, including automotive, aerospace, and electronics, and is known for its versatility and precision. . https://sendcutsend.com/Send Cut Send - Online Laser Cutting, Waterjet Cutting and CNC Router ServiceIn this video: The first video in a new series on bendin.

Sheet metal fabrication is the process of turning flat sheets of steel, aluminum, titanium or other metals into metal structures or products. This transformation is achieved through a series of techniques such as cutting, punching, folding, bending, stamping, welding, and finishing. The process generally consists of three key stages: cutting . Sheet metal fabrication is the process of transforming sheet metal into finished products ready for sale and use. Fabricating a product from sheet metal requires many processes and pieces of equipment (e.g. cutting sheet metal and sheet metal bending) all coordinated to turn the raw material into a finished product.Bending is a process where the sheet metal is deformed along a straight line.It involves changing the angle of the metal sheet to create a bend, which forms a ‘V’, ‘U’, or channel shape over a straight axis.

metal fabrication cumbria

Sheet metal bending is a forming operation where sheets are deformed plastically to change their shape. During sheetmetal bending, the material is stressed beyond its yield strength but below the ultimate tensile strength. After bending a sheet metal part, the total length of sheet metal is more than the flat length.

Whilst bending sheet metal is a useful strategy for many different types of projects, sheet metal bends can be easy to mess up if you get the technique wrong. To ensure you create the professional bend you are after, follow these helpful tips. Tip 1: Choose the Right Materials.

Sheet metal bend allowance is a critical element of sheet metal bending that compensates for material stretch and spring back during bending. The bend allowance involves adding a calculated dimensional compensation to the flat length of a sheet metal component to ensure that the final part is bent to the specified dimensions.

5. Sheet Metal Bending Collisions. Whether it’s an asteroid, a motor vehicle, or a sheet metal part, collisions really aren’t a good thing. In the world of bending, a collision occurs when the material to be bent contacts any surface other than the dies. Top Vs. Bottom Bending. Air and bottom bending are two of the most dominant sheet metal forming methods. Air bending consists of stressing the sheet past an open die until the die angle is reached, and this shape depends on how much stress is .Sheet Metal fabrication is the creation of useful metallic parts and structures by the application of multiple fabrication processes. Sheet metal fabrication is basically a broad term that involves various complex processes like cutting, forming, bending, welding, machining, and assembling. Fabrication shops or Fab shops are the places where .The bend allowance is intended to compensate for stretching of the sheet metal that occurs in a bending operation when the bend radius is small relative to the stock thickness. In principal the bend allowance equals the length of the bent metal along its neutral axis.

Also is a crucial factor in sheet metal fabrication. In a 90-degree bend, the setback value is equal to the bend radius plus the thickness of the metal sheet. By knowing the setback size, we can determine the bending . A common problem in both the sheet metal and plate industries involves parts designed with an inside bend radius much tighter than necessary. It can wreak havoc in the press brake department and cause cracking on the .

In the die, the bending punch is pressed against the sheet metal workpiece at the bending line. Sheet metal bending angle depends on the travel of punch against the sheet metal workpiece. And the internal bend radius depends on the punch radius. As a result, the operator can use the same punch and die to bend different sheet metal parts.Sheet Metal bending is a fundamental process in the manufacturing industry, used to shape and form metal sheets into various configurations. So, It is a versatile technique that allows for the creation of complex and precise components used in a wide range of applications, from automotive and aerospace to construction and electronics. . The bending allowance calculator provided below simplifies the process of calculating the bending allowance value, which is crucial for accurate sheet metal fabrication. Bend allowance is the length of the neutral axis between the bend lines, which helps in determining the correct blank size for a bent part.

Sheet metal bending involves creating a controlled deformation to form a small radius arc. Unlike roll forming, which produces larger radii, bending typically results in tighter curves. Regardless of the bending method employed (air bending, bottoming, or coining), achieving a perfect right angle is physically impossible due to material .A sheet metal part looks wonderful. I'm just concerned about the one-off pricing since this is a school prototype and I'll probably have to make a few iterations. I am also building a robot arm. When bending sheet metal, Inventor states the flange as being bent up when inserting bend notes on drawings but the bend line is actually bent down as would be the case on the press brake as the knife presses into the vee. Does anyone know of the BS or ISO standard drawing principle for this notatio.Sheet metal fabrication tolerances are often slightly larger compared to CNC machining tolerances, as bends in the material can cause the material to stretch. It’s important to note that the more processes a part undergoes, for instance if a part has multiple bends, the more difficult it becomes to achieve tight tolerances. .

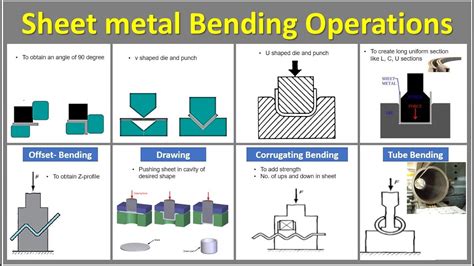

What Is Metal Fabrication? Metal fabrication is a process of forming products from sheet metal. Metal fabrication is a step by step process of designing, cutting, bending, shaping, and joining metals. Metal fabrication demands much more than just joining two metals. The following are some processes involved in metal fabrication.7 Types of Sheet Metal Bending. Notably, the metal sheet bending depends on many factors. Those include metal thickness, bending angle, and bend allowance. All these factors must be considered before starting the bending process. These factors will always be important no matter what bending type you use. Here is the list of different types: Air .

Sheet metal bending should be as close to perpendicular as possible to the direction of the metal fibers. When the sheet metal bend is aligned with the direction of the metal fibers, it is more likely to crack at the bend and have low bending strength, making it prone to breaking, as depicted in the accompanying figure. .

sheet metal bending guidelines

Brackets are structural architectural elements made of wood, PVC, urethane and other materials. They feature a vertical support that forms a 90-degree angle that attaches to a countertop or shelf being supported. There are .

what is sheet metal bending|sheet metal bending guide