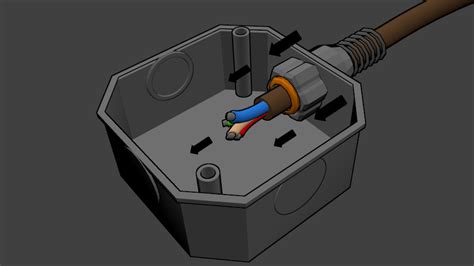

how do you knockout junction box holes Here's how to remove a knockout in order to run wires through the electrical box. Knockouts are partially stamped, quarter-size openings in the electrical boxes.

Explore & source all the CNC replacement parts you need to keep your machine in top working order. Connect with us if you need help finding the correct part.

0 · knock out electrical junction box

1 · knock out electrical box removal

2 · junction box knockouts

3 · junction box knockout removal

4 · how to remove electrical knockouts

5 · electrical box knockouts without welding

6 · electrical box knockout removal instructions

Most precision turned parts products boast high quality and low MOQs with direct .

A "knock out" or "KO" is a partially stamped opening in electrical enclosures that allows quick entry of a wire, cable or pipe via connector or fitting to the interior. With the right information and technique, you should be able to remove a "KO" from electrical panels and . In this video I will show you how to get a knock out of a 4x4 square box.

I have an electrical box that has knockouts but they aren't spot welded like usual, these look like solid circles. I have attached a picture of what they look like from the outside, what is the best way to remove these?

In this tutorial, we'll show you how to remove knockouts from QO™ and Homeline Load Centers, allowing for smooth installation of the main wiring and branch load wiring. ️ Please note that in . In this video, I’ll go over how to drill out electrical box knockouts with a standard hole saw bit rather than buying the expensive knockout drill kit.1” Mil.

Here's how to remove a knockout in order to run wires through the electrical box. Knockouts are partially stamped, quarter-size openings in the electrical boxes. It looks too small to let in critters so probably won't cause any problem by leaving it in, but the answer below shows what you would use if you want to cover it. To use the knockout plug (as in the answer) first you remove .

knock out electrical junction box

Knockouts are small, round openings in the side of an electrical box that allow wires to be brought into the box. They’re typically made of metal or plastic, and they can be removed with a simple tool. In this article, we’ll show .

Drill small hole in the center of the desired knockout (from the inside). Drive a long self-tapping metal screw into the newly drilled hole until it is firmly in place. Take a claw-hammer or kitty-paw to pull on the screw until you . Knockouts are a prefabricated hole located in your circuit breaker or panel box. When circuit panels are installed, there are empty spaces left available for future use. To cover these empty spaces, the box has small .

It can be easy to damage the collar for the smaller fitting when trying to knock out just the inner knockout. I always have 7/8" and 1 1/8" hole saws in my tool bag and if the ko's don't show movement after the first couple .

In this video, I’ll go over how to drill out electrical box knockouts with a standard hole saw bit rather than buying the expensive knockout drill kit.1” Mil.

knock out electrical box removal

I am using the remodeling cans with the metal junction box attached to the can assembly. I will have two, 3-wire 12 gauge cables coming into the junction box for each light. This is the typical wiring with shielding I see in construction. When I remove the knockout, the hole is quite sharp and I am fearing that over time, this could cut into .

Just through the side and not the top. There’s no code for clamping wires as they enter a junction box. Which makes sense because you don’t do that when you pull wires through EMT. I have this plastic residential single gang box. I haven’t found a code violation about drilling a hole in the side of a junction box either. I purchased an outdoor GFI plug and box combo at Home Depot (Canada). The instructions I saw online talked about the inner box being metal and that you simply unscrewed the cap over the box hole you wanted to use for the cable - in this case the one on the back of the box because the wire comes out from the wall.

Electrical - AC & DC - can you drill your own holes in plastic boxes? - The person im working with would like to drill out a hole for the entry of bx cable in a plastic box. . but I have never needed to do the same for a junction box. Upvote #5 10-29-03, 04:25 PM T. Tim T. Member. Thread Starter. Join Date: Sep 2003. Location: USA. Posts: 165 .Call a pro dude or get online and do some research. I gave you the answer you asked for. The other guy explained it. I get paid an hour to problem solve this kinda shit and make material lists. You want to pretend to know better so good luck.

Regardless, any wire entry into a box requires a strain relief clamp, mainly to protect the wire from damage from the box edge, unless the labeling and instructions tell you otherwise. Which they would do, if the box had been designed, tested and certified to .Install a 1/2 inch connector in the box and using a 1” hole saw use the connector to keep you centered and drill through .. it will give you the hole you desire in no time. Cheaper than a hole punch or even a step bit. Just take it slow at 1st and the .

Re: covering unused holes in boxes Hey all, my 2 cents: a hole in the back of a pancake box seems bad and it is so easy to correct that why wouldn't you just do it? One way, remove the box, use a 1-inch or so speedbore and drill a little so that a snap-in KO seal will sit in there a still allow the box to sit flat on the surface. Student training aid for practical skills how to cut a hole in a surface plastic electrical box so a cable can enter. Includes a full demonstration and the p. You will need to drill a hole maybe 3/8" depending on the punch set. You then place the bolt through the die, then place the bolt through the hole you drilled, then thread the punch on the end of the bolt. Tighten with an appropriate wrench and it will give you the hole you need. Do not forget to remove the scrap piece of metal from the die.(since you cannot buy an lb or junction box behind the drywall) So wondering if there are any junction boxes with have 1 1/4" knockouts at the back I can then run conduit to the panel outside and can then add a mud-ring (if not deep enough) or .

junction box knockouts

Whether or not just using a reducing bushing is code-compliant depends on the type of electrical box and use involved. If it is just a "metallic outlet box", then a reducing bushing also listed for bonding use (as apparently most are) is OK, even if all the concentric rings in the knockout have not been removed.If the box is some other enclosure than a metallic outlet box, .Take a piece of wood and make a hole in it with the hole saw for 1 1/4 pipe. Clamp it over the hole you need to make larger the wood will support the hole saw so it doesn't slide around. Another option is to try and use an 1 1/8 hole saw as the arbor for the hole saw for 1 1/4. Edit: sorry if that doesn't make sense.

Flathead screwdriver + hammer. Normally this is a bad idea for your screwdriver, but in this case you need to crack or shatter a hole in the opening. Once you have a hole, stop. Drill it. Once you have a hole, get a . Re: 4X4X4 holeless PVC Junction Boxes Good question these boxes have to be field fitted since no ko`s.I have used them as j boxes on lomg runs,but have never used them as a fixture mounting lid.Water infiltration is what came to mind foremost.I would be inclined to use a meyers hub for two reasons.First as I have already saidwater infiltration.Second heat .Side cutter and flat head. Start small and work your way up or else. You are gonna make bigger holes and damage the integrity of the other hole. Once the small hole is gone. Use side cutters to cut and bend the next hole. Do not use the flat head again.Place a flat-head screwdriver into the slot of the electrical box knockout that is to be removed. Oftentimes, the screwdriver must be placed on the edge of the slot nearest to the bottom of the enclosure. Hit or tap the end of the screwdriver to remove the knockout and dislodge the rest of the knockout by hand if needed.

Exception: Where nonmetallic-sheathed cable or underground feeder and branch-circuit cable is used with single gang boxes no larger than a nominal size 2¼ in. x 4 in., mounted in walls or ceilings, and where the cable is fastened within 8 in. (203 mm) of the box measured along the sheath and where the sheath extends through a cable knockout no . Electrical - AC & DC - Code question regarding drilling a small hole in an electric junction box - I'd like to mount the side of a metal junction box I currently have to a stud. The only mounting holes currently in the junction box are in the bottom of the box- there are none on its sides. It would be easy enough Yes, they are one way unless you really want to bend up the box. When the box is installed, I usually take a small screwdriver, slotted, and tap it into the crack between the knockout and the box and twist the knockout out a bit. Then grab it with a pair of needle nosed pliers and twist it completely out. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

24 in x 3 ft galvanized steel sheet metal

How do I prevent this, or if it's already happened, fix the now over-sized hole? electrical; junction-box; Share. . 20.8k 18 18 gold badges 95 95 silver badges 135 135 bronze badges. asked Jun 15, 2017 at 16:35. Roger Roger. 21 2 2 bronze badges. 1. If you do accidentally knock out the wrong size hole you can use reducer bushings to fix it . Knockouts are partially stamped, quarter-size openings in the electrical boxes that service such things as outlets and switches.Once removed, a knockout allows electrical wires to be run in and .

Multiple cable entries shall he permitted in a single cable knockout opening. Solutions? If you do not want to reinstall new boxes, you need to plug any holes that are not occupied by electrical cables. Then, be sure you have secured your cables to the stud or some other suitable surface within 8 inches of the box. Please note this exception .Commercial Electric's non-metallic weatherproof boxes are rated to protect branch circuits in wet, damp, and/or dry locations. Powder coat finish provides maximum weatherability and scratch resistance. Boxes can serve as a junction box or as housing for receptacles, switches, and GFCIs. Hubs accept all threaded fittings and threaded conduit.

24 inch square sheet metal

High-quality CNC roughing end mills will not only ensure better performance but also increase the lifespan of your tools. Research and read customer reviews to gauge the quality of the products offered by different wholesalers.

how do you knockout junction box holes|electrical box knockouts without welding