how to build a box with metal studs This guide will show you what you need to know before working with metal or steel framing. These useful tips can save you time and make your project go a lot. Wendling Sheet Metal has vast experience in building and innovating custom sheet metal products to meet the unique needs of a wide variety of industrial customers.

0 · steel stud framing table

1 · steel stud framing dimensions

2 · steel box beam framing

3 · metal stud framing table size

4 · metal stud framing sizes

5 · metal stud framing chart

6 · metal stud framing

Question 4) Any documents/correspondence regarding the decision to install a yellow box outside West Hill fire station. Answer: West Hill, SW18, is on a busy stretch of the South Circular.

This is a complete detailed instructional video on how to construct a metal stud box beam into a wall, complete with bottom header and layout. This video will teach you how to build a box beam for metal stud framing. Learn metal stud framing RIGHT HERE: https://bit.ly/ExpertFramingLessons 🚧 Best clamps for building. This guide will show you what you need to know before working with metal or steel framing. These useful tips can save you time and make your project go a lot. This article will discuss the benefits of using metal studs, both structural and non-structural in a metal-framed building and their advantage over wood. Metal studs are gaining popularity among homebuilders and contractors.

steel stud framing table

steel stud framing dimensions

There are two basic steel framing components: studs and tracks. The track functions as the top and bottom plates. When you’re metal stud framing, lay out your walls and openings just like you would with wood, but when you . Steps to Attach Electrical Boxes to Metal Studs. Installing electrical boxes on metal studs requires attention to detail and adherence to local building codes. Follow these steps for a safe installation: Measure and mark the .

There are so many DIY undertakings to consider when using metal wall studs, such as finishing your bathroom walls, a deck, outdoor kitchen, partition, storage space, tiny shed, or, more commonly, the bones of your .

Follow these steps: Install track channels: Begin by attaching the top and bottom track channels to the floor and ceiling using screws and a drill/driver. Ensure they are level and secure. Cut and install metal studs: Measure and cut metal studs .

Steel framing is used in most office and commercial construction, and it has several advantages over wood. Steel studs are perfectly straight, . Cover the body of the box with steel frames: After making the box, cut the steel frames to match the volume of the box. . How to Build a BBQ Island with Steel Studs. Now I will cover the steps you need to take to build a BBQ island with steel studs. The first step is choosing the . We’ve been asked by a number of clients how to size and build with metal studs a few times. While it’s always good to go with an engineered design there are tables for metal stud framing that can help us size steel .

This video will teach you how to frame a metal stud wall around large ducts. Access the latest in construction video right here: https://goo.gl/wSSry6 Maste.

This guide will show you what you need to know before working with metal or steel framing. These useful tips can save you time and make your project go a lot.Shoot its only in my mind. In essence, I’m thinking of a box 72” x 75” using metal studs. I imagine covering said box with say 1/2” plywood on bottom and top and placing a mattress on it. The 4 actuators would be positioned on each corner and push the frame horizontally up to the ceiling of my cargo trailer. Thanks for watching! Installing and wiring a 100 Amp sub panel in my metal building. Follow along as I build my dream garage and share the highs and lows along the way.#metalshop.

Building a Bulk Head from start to finish.Links to tools:Milwaukee Impact driver. https://amzn.to/2HQdn1lDewalt laser level. https://amzn.to/2vwTaeiOcciden. As for boxes they make metal 4x4 boxes for this with a flange to screw into face of metal stud. An alternative is to screw a 18" long 2x4 to std where you want box and then use any box you like screwing it into the wood. Good day all In this quick tip video we go over a few ways to cut two two of the most common headers in metal studs. Ears and shoesWe explore- Cuttingheade.

steel box beam framing

In this video we show how we build a Soffit or Drop Ceiling around ductwork using Metal Studs. Besides this metal stud framing method, Wood can also be used.

Why I chose steel for my frame.Note: If you build a tube frame, be sure to design it so that if any water gets into the tubing, it can drain all the way out . This post shows how I went about simply framing a wall in a shipping container. I needed to build a room in the back of the shipping container that I can in.

I make a super-strong steel frame for my greenhouse roof using the simple and versatile #tinktube system. Get 10% OFF your first order from tinktube: https:/.

steel is nice to work with, light weight, true, no warping. I just built a wall from steel studs. They get their strength from fastening them to something rigid and from the drywall applied to them. Go to a supply house/big box store and take one off the shelf to see what they feel like. Steel studs are not meant for weight bearing walls. Step 3: Measure and Cut Metal Framing Studs. Using your blueprint, measure and cut the metal framing studs to the desired length using a saw. Make sure to double-check all measurements before cutting to avoid any . This video will teach you how to frame a simple closet with metal stud in under 5 minutes. Access the latest in construction video right here: https://goo.gl. How do you install doors and trim on steel studs when it has almost no holding power? Watch to find out.

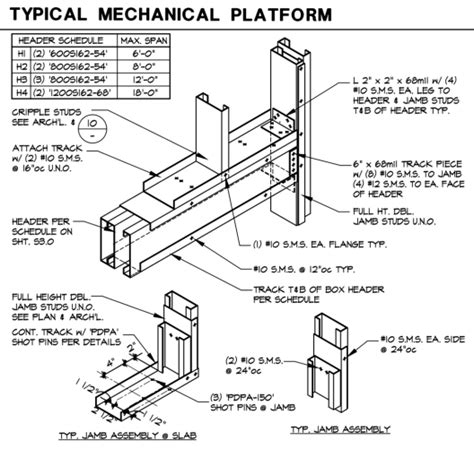

Metal studs and steel framing can be used in both residential and commercial building projects, making them an appealing choice for any project. Typically referred to as steel studs, or light gauge steel studs, they are commonly used to frame interior walls. They are non-combustible, UL fire-rated, and manufactured in gauges from 25 to 12 (18 . The cheapo studs at big box store all say they are "non structural". Because I want the mantle to be solid on top of this framing I would rather have heavier studs intended for use in bearing walls. I figure 2x4 sized heavy metal studs would provide a solid base for a tile surround that has a mantle sitting on top of it. Back to back headers are the sister metal stud headers of box beams. The components are the same as the box beam except that the studs are turned inside out. Again two tracks are used on the top and bottom of the assembly with their webs facing the ground. The strong axis of the studs are fastened together. The panel can be mounted on a metal building frame. You must create a grounding electrode system at the detached building and bond the metal structure to the electrode system. At best #2 aluminum is only good for 90A, and only 75A if you have 60°C conditions. You can use a 100A (or larger) panel, but you will need to feed it with a smaller .

Length should be [thickness of drywall] + [thickness of plywood] + [3/4 "]. You want to make sure the actual threaded part of the screw makes it into the steel studs. If you are doing plywood, you want the plywood to hit at least 2, preferably 3 studs. If you have 12" on-center studs, you'll want a 26 or 28" wide strip of plywood. Unlike wood, steel studs are reliably straight. Cut one stud to size and use that, along with a level, to mark the location of the top plate at both ends, and snap a line to guide placement. Don’t worry about cutting your studs to fit perfectly. It’s completely unnecessary in metal stud framing.This video I show you 3 examples how to build a bulkhead with metal studs. Access the latest in construction video right here: https://goo.gl/wSSry6SimplyWis.I am trying to build a wall niche with shelves in a bathroom wall that is made of metal studs. It is next to a vanity (aka not tiled, or in a shower). I am finding a lot of info on building wall niches in standard wood frame walls but not much when it comes to metal studs.

How to frame steel building with wood for insulation and walls. Episode 23.Products in our Amazon store used in this video (costs nothing extra to use thes.

The silicon bronze rod’s lower melting point makes it ideal for joining together thin sheet metal, galvanized steel, and nuts and bolts, too. It’s nice for sheet metal work because the lower melting temps means less heat, which equals less warping when compared to TIG with, say, an ER70 rod.

how to build a box with metal studs|metal stud framing chart