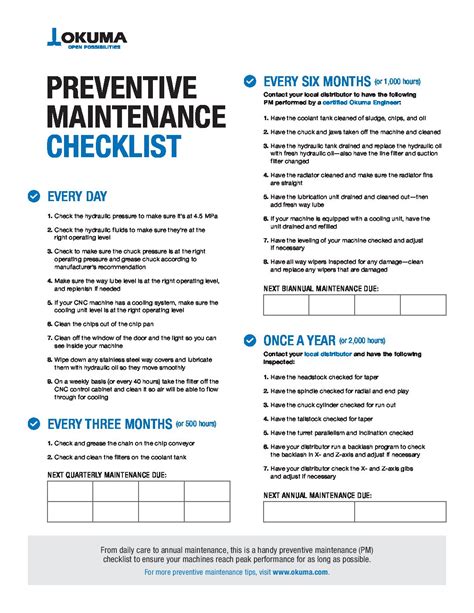

cnc machine tool preventive maintenance Okuma offers preventive maintenance tips to help keep your CNC machine running at peak performance while avoiding unplanned downtime. . With an emphasis on preventive maintenance to keep your machine tool running, our . $7.94

0 · preventive maintenance checklist pdf

1 · okuma cnc machine maintenance checklist

2 · okuma cnc machine maintenance

3 · okuma cnc lathe maintenance

4 · cnc machine maintenance cost

5 · cnc machine maintenance checklist

6 · cnc lathe maintenance checklist

7 · ats cnc machine maintenance

The D-Box (D-Tap, Base Unit) comes standard with one Mini 4 Pin XLR input and allows 5 selectable outputs. Attaches between a V-Mount or Gold Mount plate and wherever it was .

Why is Preventive Maintenance Beneficial for you? 1. Reduces downtime. 2. Saves you money. 3. Reduces complete breakdowns. 4. Extends the lifespan of your machine and cutting tools. 5. Reduces repair costs from unexpected .Learn the importance of preventive maintenance for CNC machines. Discover best practices, checklists and how ATS can support your maintenance needs.Okuma offers preventive maintenance tips to help keep your CNC machine running at peak performance while avoiding unplanned downtime. . With an emphasis on preventive maintenance to keep your machine tool running, our .Learn the importance of preventive maintenance for CNC machines. Discover best practices, checklists and how ATS can support your maintenance needs. . A CNC machine tool breakdown is expensive and disruptive, but it is at least .

Summit Machine Tool CNC machines require routine preventative maintenance to ensure longevity and consistent operation. Staying on top of your CNC machine’s repair and maintenance ensures that the machine or any component does not break down and bring your work to a sudden halt. Daily/Weekly Preventive Maintenance for Summit CNC MachinesSince we opened our doors in 2005, the team at CNC PROS has performed thousands of preventive maintenance events throughout Arizona and now Colorado, on a variety of machine tools. CNC preventive maintenance calls through CNC PROS can be scheduled bi-annually, annually, or custom-tailored to your individual requirements.

CNC machine tool help covers all aspects of CNC. Learn CNC programming, Machining, CNC training, tutorials, CNC videos and more. . ballbar analysis, preventative maintenance, backlash, headstock, spindle, turret, tool changer and pallet changer alignments are all discussed. Get help with machine tool applications, including NC programming, G .Our techs have a combined 50+ years of experience in CNC repair. We offer repair, preventative maintenance, inspections, safety audits, parts, batteries, drive and motor rebuilds, etc. We do not sell any machinery, so we work on any brand and will .

CNC machine tool (CNCMT), as the mother machine of industry, is one type of important manufacturing equipment [1]. The performance and reliability of CNCMT determines the quality of products it has processed. . A reliability-based sequential preventive maintenance model. J. Shanghai Jiaotong Univer. (2005) Google Scholar [4] N. Cauchi, K .No matter if it is a single machine (conventional or CNC) or an entire manufacturing facility, we can develop a preventative maintenance program to meet your machine tool needs. We can customize mechanical and/or electrical contracts to meet your requirements.5. 18 MAINTENANCE A. PREVENTIVE MAINTENANCE Many of the service problems that occur over the lift of any Machine tool can be avoided through the application of proper Preventive maintenance practices. The purpose of this section Of the manual is to help you in setting up a regular schedule of Periodic preventive maintenance measures for your CNC lathe. Keeping .

PREVENTATIVE MAINTENANCE BENEFITS. Increase / Maintain Profitability by Avoiding Unplanned Downtime; Reduce Scrap Due to Wear Related Changes in Accuracy and Alignment; Extend the Useful Life of Your Machine Tool; Maintain the Resale Value of Your Machine Tool Maintain ISO Certifications; PREVENTATIVE MAINTENANCE DAILY CHECKS. 6x50 . As a typical manufacturing equipment, CNC machine tool (CNCMT) is the mother machine of industry. Fault of CNCMT might cause the loss of precision and affect the production if troubleshooting is not timely. Therefore, the reliability of CNCMT has a big significance. Predictive maintenance is an effective method to avoid faults and casualties.Can preventive maintenance extend the lifespan of my CNC machine? Absolutely. Implementing a well-structured preventive maintenance plan can significantly extend the lifespan of your CNC machine by identifying and addressing potential issues before they escalate. What benefits does eWorkOrders offer for CNC machine maintenance?

Shibaura Machine Company, America has a top-tier field service team trained to support you on your CNC machine tool preventive maintenance needs. Contact us at (888) 593-1616 or submit an online service request to learn more about available support options.Verify machine level VMC – verify spindle sweep Lathe – verify turret square to spindle face Check lubrication is reaching the spindle Inspect drive belts Inspect tool holders/grease pull studs. Inspect the rotary oil level (mill) Verify gearbox/motor operation Inspect tool changer and lubricate Inspect spindle taper condition

Your preventive maintenance program should include a set procedure for reporting issues and an accessible communication channel for doing so. Having a clear reporting procedure makes it easier for problems to be reported and fixed promptly. . The Advantages of Routine Maintenance for CNC Machine Tools. Following the recommended maintenance .

Luo et al. [15] proposed a hybrid predictive maintenance method for CNC machine tools based on the degradation mechanism, a multi-domain digital twin and a system state-space model. Using multi . Predictive maintenance is a revolutionary concept in the manufacturing industry. Not only has it proven integral to substantially extending the lifespan of CNC machines and critical manufacturing equipment, but it also .Unlock the secrets of accuracy in CNC machines! Discover how preventive maintenance, vibration control, and precision layering can improve your CNC machine’s performance. Dynemech’s reliable solutions pave the way for accuracy, efficiency and ROI. Let .

preventive maintenance checklist pdf

With an emphasis on preventive maintenance to keep your machine tool running, our CARE Kits help ensure your Okuma machine tool's mechanical, electrical, lubrication, airflow, and coolant systems will continue to operate in “like-new” condition. . Through scheduled preventive maintenance actions, you can protect valuable CNC machine .

UMC Maintenance Table: Automatic Tool Changer - SMTC: Maintenance Item: Interval: Clean the chips from the tool changer. Weekly: Inspect the arm plunger and adjuster assembly. Six Months: Clean and lubricate the pocket tool plungers. Six Months: Clean and lubricate the track on the carousel housing that the tool pocket rollers ride on (SMTC30 .Regular maintenance is crucial to keep your CNC milling machine in optimal condition and ensure maximum productivity. This comprehensive checklist will help you establish an effective preventive maintenance routine. By following these steps, you can prevent breakdowns, avoid costly repairs, and prolong the lifespan of your CNC milling machine. The importance of proactive CNC machine maintenance. CNC (or Computer Numerical Control) machines are a critical piece of equipment in many manufacturing facilities. When a CNC machine breaks down or experiences a severe fault, the whole manufacturing process has to be halted till the problem is rectified.

12. CNC Machine Operating Modes AUTO Mode: In automatic mode, individual NC traversing programs are processed. The axes cannot be traversed by means of the direction keys. In this mode machine works in part programs .Part program is program of particular job. part program contains various codes like that the numeric value of axis position ,tool command, .

From before machine startup until after shutdown, preventative CNC maintenance takes place throughout the operating cycle. Detailed below are a few main areas on which to concentrate time and effort. . Billor McDowell provides repairs on all makes and models of CNC machine tools. We are recognized throughout the Southern United States for .Here are a few preventive maintenance tasks you can perform to keep your CNC machine running smoothly: Daily Preventative Maintenance. Check hydraulic pressure, fluids, chuck pressure, lube levels, and coolant levels; Clean out chips, grease parts, windows, and doors, and wipe down and lubricate way covers; Every 3 months or 500 hours On Your . Why CNC Machine Tool Preventive Maintenance is Worth it. Computer Numerical Control (CNC) machines are heavy-duty and extremely accurate performers. Machine tools such as lathes, milling machines, and multi-axis machining centers perform multiple complicated machining tasks at the same time and sometimes lead to long uninterrupted periods of .preventative maintenance. houston texas cnc repair of most major brands 10 service technicians with over 200 years of experience. our guarantee! we fix it or the labor is free! cnc machine tool troubleshooting & repair. supporting all major brands with fanuc, siemens, heidenhain, mitsubishi, mazatrol, osp, fadal, milltronics & haas controls

okuma cnc machine maintenance checklist

Choose from a blank box for mounting flat items or for creating your own cut out, a single, double, triple, quad or round cut out for your desired electrical boxes. We also make custom boxes for mounting your electrical box service to or larger light fixtures ...just give us some measurements!

cnc machine tool preventive maintenance|ats cnc machine maintenance