sheet metal bending calculator Use SendCutSend’s bending calculator to input your desired material . Faraday Cage Garage Will a metal building protect from EMP? An enclosed metal structure will certainly provide some amount of protection (attenuation) in the event of an EMP (electromagnetic pulse).

0 · sheet metal calculation formula

1 · sheet metal bending calculator free

2 · sheet metal bending angle chart

3 · sheet metal bend deduction chart

4 · calculating bend radius sheet metal

5 · calculating bend allowance sheet metal

6 · calculate sheet metal flat pattern

7 · blank size calculator sheet metal

While metal roofs are generally energy efficient, black metal roofs can absorb more heat compared to lighter-colored roofing materials. This heat absorption can potentially .

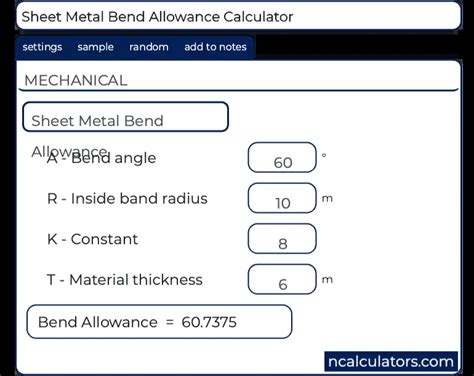

Our comprehensive online sheet metal bending calculator is an essential tool for precision metalworking, enabling you to swiftly and . Use SendCutSend’s bending calculator to input your desired material . With this bend allowance calculator, you will learn how to calculate the length of a sheet metal bend so you can optimally create metal bendings without a bend allowance chart. It works as a bend deduction calculator too!

Bend Allowance Calculator. Calculate the bend allowance, bend deduction, and setback for a bent piece of sheet metal, or use this information to determine the K-factor. Our Sheet Metal Bend Calculator takes into account the material thickness, bend radius, bend angle, and K-factor to provide accurate bend allowance and bend deduction values. This ensures your bends are accurate, .Online bend deduction calculator. Automatically calculate bend deduction, bend allowance and K-factor for sheet metal fabrication and forming.Wipe Bending Force Calculator. Sheet thickness (in): Die edge radius (in): Punch edge radius (in): Bend length (in): Ultimate tensile strength (psi): Factor of safety: Bending force (lb):

Our bend deduction calculator helps you calculate the correct values for your sheet metal bending projects, ensuring accurate results and minimal waste. Try it out for free today!

sheet metal calculation formula

With this free online tool we quickly get the sheet metal bend deduction, and therefore the sheet metal blank initial flat length, from the finished part measurements. You only have to insert .The tool can calculate the required bending force for bending aluminum, stainless steel, mild steel, and Weldox® or Strenx® high-strength steels. Now that you know the tonnage and .Sheet Bending Calculator is used to calculate sheet bending allownace, bend deductions, sheet bending plate raw size Sheet Bending Calculator is very helpful in sheet metal fabrication industry, process equipent fabrication industry, .Sheet Metal Bending Force Calculator. Facebook Youtube Instagram Pinterest Tiktok. Get Free Quote. In the realm of metalworking and sheet metal fabrication, precision is paramount. One crucial aspect that engineers, designers, and technicians often need to calculate is the bending force required to form metal sheets into desired shapes. The .

Sheet Metal Bending Calculator (Free to Use) Y Factor Calculator; Bend Allowance Calculator; Bend Deduction Calculator. Recommended for you: Press Brake FAQs: Get Your Ultimate Answers; Press Brake Bending Basics: .

sheet metal bending calculator free

The bending allowance calculator provided below simplifies the process of calculating the bending allowance value, which is crucial for accurate sheet metal fabrication. Bend allowance is the length of the neutral axis between the bend lines, which helps in determining the correct blank size for a bent part. The following equation is used to determine the total flattening length when using the bend deduction value: L t = A + B – BD. Where: 𝐿 𝑡 is the total flat length.; 𝐴 and 𝐵 are the lengths of the two straight sections of the sheet metal before the bend (as shown in the figure).

We generated the following bend allowance chart using the sheet metal bend allowance calculator for steel, assuming the K-factor of 0.45, bend angle of 90 degrees, and inside radius of 0.05 inches (1.3 mm). The actual K-factor may depend on the type of bending operation, the thickness of the sheet, and the material.

Calculate bending parameters quickly and simply Use the TRUMPF BendGuide to calculate key bending parameters quickly and simply: . Die width; Open-height check; Inner radius; Sheet thickness conversion; Tool weight calculation; Sheet metal weight calculation; Download the app In the "More" menu item, you can convert the units of measurement .Online bend deduction calculator. Automatically calculate bend deduction, bend allowance and K-factor for sheet metal fabrication and forming. Skip to content. Request a Quote (916) 419-0580; Search. Toggle navigation Menu [email protected] (916) 419-0580; Services. Services;

K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of neutral axis and sheet thickness. During sheet metal part bending, the inside bending surface is compressed, whereas the outer surface is stretched.Sheet Metal Bending Parameters Calculator Here you can insert the characteristics of the sheet metal to be bent (internal radius, V-die opening and minimum flange) . The tool can calculate the required bending force for bending aluminum, stainless steel, mild steel. Bending Force Calculation Our press brake bending calculator can help you based on the [.]BendCalc is a bend deduction and bend allowance calculator for sheet metal air-bending. Actually BendCalc is more than that, BendCalc is five calculators in one. . Calculator 2: Calculates Bend Deduction and Bend Allowance given bend angle, material .

steel filing cabinets makro

More Than One Sheet Metal Bending Formula. Press brake technicians can use various formulas to calculate bend functions. For instance, in this article we have used the following for outside setback: OSSB = [Tangent (degree of . For instance, if the sheet metal to be bent is mild steel, with a thickness of 4mm and a bending length of 3.2m, the theoretical width of the bottom die opening should be 8 times the thickness, which is 32mm. Input these figures into the calculator above (remember the units are in mm), and we get a value of 106.12 Ton. This means you’ll need a minimum bending .

Calculates the bending force for bending a piece of sheet metal using wipe bending (also called edge bending). The calculated tonnage can be used for the selection of a press brake machine. Login . Calculate the required force to bend a piece of sheet metal using wipe bending, also called edge bending. In this process, the sheet is held .Bending Springback Calculator. After a bending operation, residual stresses will cause the sheet metal to spring back slightly. Due to this elastic recovery, it is necessary to over-bend the sheet a precise amount to acheive the desired . K Factor Calculator for Sheet Metal Bending (Online & FREE) Sheet Metal Bending: Everything You Should Know Explained; Bend Deduction Calculator, Formulas & Charts; Precision Sheet Metal Bending with .

How long does it take to bend a sheet metal box. According to data collected by one of our customers, it takes several minutes to bend a sheet metal box of considerable size.The process has an important manual component, generates faulty parts, can cause damage and injury, and takes a long time. A box with rounded edges requires two operators and almost 2 minutes to .Metal bending involves the deformation of a metal sheet along a straight axis, altering its shape without reducing its cross-sectional area. Accurate bending calculations are essential to prevent material failure, such as cracking, buckling, or excessive thinning, which can compromise the structural strength and aesthetics of the final product.Bending rule and rulers to calculate the tonnage of "U" profiles, "Z" profiles, flattened profiles and offset Z profiles. By using this site you agree to the use of cookies for analysis and personalized content.Reference for parameter comparison of sheet metal bending. Press brake bending calculator. Our press brake bending calculator can help you based on the material, thickness of part, angle and length of bending to obtain all necessary parameters you need. Normally all the values are theoretical without guarantee, meanwhile it can help you to .

steel filing cabinets wise supply

Flat Plate Deflection Calculator Simply Supported | Flat Plate Stress Calculator The plate deflects. The middle surface (halfway between top and bottom surfaces) remains unstressed; at other points there are biaxial stresses in the plane of the plate. . Bending stress at center (N/mm 2) = psi Reaction load at center of long side (N/mm) = lbs .This K-factor calculator will assist you in finding the K-factor for sheet metal. Sheet metal is the building block of structures, from forming the body of automobiles to the skin of aircraft wings. The roofs on the house (cf. roofing calculator) or the geyser that supplies water for your warm showers and baths all use sheet metal for the fabrication process.Sheet Metal Bending Equation and Calculator. Manufacturing Knowledge Menu Sheet Metal Knowledge. The following illustration shows the equation / calculation for determining the bend line to mold allowance when forming sheet metal. Most sheet metal materials will conform to the calculations. This page also includes a link to a on-line calculator. Have you ever wondered how to calculate the exact force needed to bend metal sheets? This article will introduce you to the V & U-shaped Bend Force Calculator, a powerful tool in sheet metal fabrication. By the end, you'll understand its importance and how it ensures precision in your projects. Let's dive in!

Calculate K factor and bend allowance for sheet metal bending; Calculate length and weight of a sheet metal coil; Calculate radiused bump bending; Online calculator for bending sheet metal boxes; Saving in tool changing; Shearing force calculator; Sheet metal bending parameters calculator; Sheet metal weight calculator Fig.: Bending specs for 0.040” 5052 Aluminum. Bend Length. The bend length, or width of the flange, is dependent on, wait for it, the material properties: For the 304 Stainless in the previous example, the maximum length is 36” while a thinner, more ductile material like the the 5052 aluminum can easily be bent all the way up to the max part size of 44”.Sheet metal bend allowance calculator - formula & step by step calculation to find the flat pattern length when a bend is dimensioned either from the centre of radius or a tangent point of radius or the outside tangent point of the radius on an acute angle bend. BA = [A x (π/180) (r + (K x T))]. The bend angle A in degrees, inside bend radius .

sheet metal bending angle chart

We can cut lumber, mini-blinds, pipe, rope, chain and more. Lowe’s also offers free pipe threading and cutting for any size of galvanized or black iron pipe. The process involves a machine‐based cutting operation with a metal wheel that creates threads in the ends of pipes.

sheet metal bending calculator|calculate sheet metal flat pattern