cnc machine for brass parts You need a rigid milling machine instead of a desktop CNC mill to make brass parts with tight tolerances and complex geometries. DATRONs are built for precision machining with their rigid construction, high RPM spindles, and . Backed by both our 5-year worry free warranty and hundreds of positive customer reviews, this box spring is about as easy as decisions get. BUILT TO LAST – An interior framework made of durable steel and reliable steel slats will support any foam, latex, or spring mattress; twin size supports up to 350 lbs, while all other sizes can support .

0 · speeds and feeds for brass

1 · machinability of brass

2 · is brass easy to cut

3 · copper and brass machine shops

4 · cnc machine for brass

5 · cnc brass parts

6 · brass machinability chart

7 · brass against the machine coplot

Find many great new & used options and get the best deals for Zvex Box Of Metal Distortion Fuzz Factory at the best online prices at eBay! Free delivery for many products!

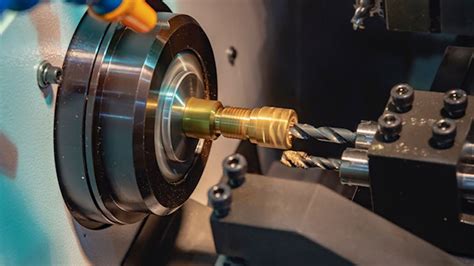

CNC machining brass lamp parts. Brass CNC machined parts ensure precision and durability in many fields. CNC turning crafts these parts. They suit custom needs like precision components. Industries like automotive .Discover the benefits of precision brass CNC machining for custom brass parts. Get insights on brass types, applications, and more. Order your brass parts with confidence.

CNC Machining Processes for Brass. There are several methods to machine brass parts depending on the requirements of the project: CNC Milling: In brass CNC milling, a rotating cutting tool removes material to create precise shapes .You need a rigid milling machine instead of a desktop CNC mill to make brass parts with tight tolerances and complex geometries. DATRONs are built for precision machining with their rigid construction, high RPM spindles, and .

Learn about brass, a versatile metal for CNC machined components. Find out the types, properties and applications of brass alloys C260 and C360, and download a CNC machining design guide. CNC machining of brass includes a subtractive assembly approach using CNC machine tools, such as carbide inserts and mechanized controls. These devices work to wipe out layers of material from a metal workpiece. The .

Brass CNC machining is a specialized manufacturing process that uses Computer Numerical Control (CNC) technology to automate the cutting, shaping, and fabrication of brass . Brass CNC turning involves the use of a lathe to create cylindrical parts by cutting away brass material from a workpiece. Brass and its alloys are relatively easy to machine, have good corrosion resistance, and are .

In this article, we’ll provide a comprehensive guide to CNC machining of brass, covering the basics, tool requirements, machining parameters, and finishing techniques. Brass .

CNC machining brass lamp parts. Brass CNC machined parts ensure precision and durability in many fields. CNC turning crafts these parts. They suit custom needs like precision components. Industries like automotive depend on them for smooth operation. They use CNC machined brass parts in vehicles. In this CNC machining brass guide, we’ll examine the properties of brass and the various brass grades used for custom brass parts. We’ll also review the applications of brass manufacturing and the factors to consider when picking brass for a machining project.Discover the benefits of precision brass CNC machining for custom brass parts. Get insights on brass types, applications, and more. Order your brass parts with confidence.CNC Machining Processes for Brass. There are several methods to machine brass parts depending on the requirements of the project: CNC Milling: In brass CNC milling, a rotating cutting tool removes material to create precise shapes and designs. This process is ideal for producing complex parts like gears, brackets, and fittings.

You need a rigid milling machine instead of a desktop CNC mill to make brass parts with tight tolerances and complex geometries. DATRONs are built for precision machining with their rigid construction, high RPM spindles, and micro tooling.

square metal post brackets

speeds and feeds for brass

In this guide to CNC machining, you'll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production. We carry two brass alloys: C260 and C360. Brass is a weather and corrosion resistant metal with tensile strength similar to mild steel. It's also an easy to machine material. CNC machining of brass includes a subtractive assembly approach using CNC machine tools, such as carbide inserts and mechanized controls. These devices work to wipe out layers of material from a metal workpiece. The rate at which material is .

Brass CNC machining is a specialized manufacturing process that uses Computer Numerical Control (CNC) technology to automate the cutting, shaping, and fabrication of brass machine parts. The finished brass parts have a high degree of accuracy and precision that will be otherwise difficult to achieve manually. Brass CNC turning involves the use of a lathe to create cylindrical parts by cutting away brass material from a workpiece. Brass and its alloys are relatively easy to machine, have good corrosion resistance, and are aesthetically pleasing. In this article, we’ll provide a comprehensive guide to CNC machining of brass, covering the basics, tool requirements, machining parameters, and finishing techniques. Brass is an alloy composed primarily of copper and zinc, with varying amounts of other elements such as lead, tin, and aluminum.

CNC machining brass lamp parts. Brass CNC machined parts ensure precision and durability in many fields. CNC turning crafts these parts. They suit custom needs like precision components. Industries like automotive depend on them for smooth operation. They use CNC machined brass parts in vehicles.

In this CNC machining brass guide, we’ll examine the properties of brass and the various brass grades used for custom brass parts. We’ll also review the applications of brass manufacturing and the factors to consider when picking brass for a machining project.Discover the benefits of precision brass CNC machining for custom brass parts. Get insights on brass types, applications, and more. Order your brass parts with confidence.CNC Machining Processes for Brass. There are several methods to machine brass parts depending on the requirements of the project: CNC Milling: In brass CNC milling, a rotating cutting tool removes material to create precise shapes and designs. This process is ideal for producing complex parts like gears, brackets, and fittings.

You need a rigid milling machine instead of a desktop CNC mill to make brass parts with tight tolerances and complex geometries. DATRONs are built for precision machining with their rigid construction, high RPM spindles, and micro tooling.In this guide to CNC machining, you'll learn how to create efficient, manufacturable metal and plastic parts for prototyping and production. We carry two brass alloys: C260 and C360. Brass is a weather and corrosion resistant metal with tensile strength similar to mild steel. It's also an easy to machine material.

CNC machining of brass includes a subtractive assembly approach using CNC machine tools, such as carbide inserts and mechanized controls. These devices work to wipe out layers of material from a metal workpiece. The rate at which material is .

Brass CNC machining is a specialized manufacturing process that uses Computer Numerical Control (CNC) technology to automate the cutting, shaping, and fabrication of brass machine parts. The finished brass parts have a high degree of accuracy and precision that will be otherwise difficult to achieve manually. Brass CNC turning involves the use of a lathe to create cylindrical parts by cutting away brass material from a workpiece. Brass and its alloys are relatively easy to machine, have good corrosion resistance, and are aesthetically pleasing.

machinability of brass

square metal building house plans

Shop Zoeller Steel Control Box in the Water Pump Accessories department at Lowe's.com. This contractor grade Zoeller control box is required for 1 HP, 3-wire, 230 Volt submersible well pumps. Starts submersible well pump. Replaceable capacitors.

cnc machine for brass parts|machinability of brass