defects in sheet metal forming process pdf © 2008-2024 ResearchGate GmbH. All rights reserved. Terms; Privacy; IP . Haas Mini Mills are the industry standard for compact machining centers. They are perfect for schools, start-up shops, or as a first step into CNC machining. Loaded with full-size features, they are valuable additions for shops needing a “second-op” machine, or an additional spindle where space is limited.

0 · surface defects in sheet metal PDF

1 · sheet metal forming tools

2 · sheet metal forming model PDF

3 · sheet metal forming defects PDF

4 · sheet metal forming defect prediction

5 · sheet metal forming PDF

6 · sheet metal forming

Call VC Metals today to get free price quotes or order metal online for next day delivery. We offer free estimates on materials costs, cutting by the inch or foot on our production saws and plasma cutter. We can produce clean cuts with a precision to +/- .010 with our metal band saw.

Surface defects are small concave imperfections that can develop during forming on outer convex panels of automotive parts like doors. They occur during springback steps, after .Surface defects are small concave imperfections that can develop during .

© 2008-2024 ResearchGate GmbH. All rights reserved. Terms; Privacy; IP . In this work, the federated learning methodology is applied to predict defects in sheet metal forming processes exposed to sources of scatter in the material properties and process.In this paper, we take a machine learning per-spective to choose the best model for defects prediction of sheet metal forming processes. An empirical study is presented with the objective . This paper focuses on developing a generic functional data analysis based approach to quantify geometric error/shape error which are generated by process or material parameters (such as material thickness, stamping speed .

In this work, an approach to extract information from a sheet metal forming processes, exposed to sources of scatter in the material properties and process parameters, is proposed in order to .

In deep drawing metal sheet is subjected to high punch pressure which causes deformation of material, during deformation stresses are generated in various zones, which leads to various .Accurate prediction of forming defects is essential for the sheet metal forming process. In this paper, an approximation model technique based on Gaussian process regression(GPR) is .

Some of these defects are caused by the forming tools (types 5, 9, 10, 14), by the friction regime (types 4, 13) or by the mechanical and metallurgical properties of the material as well as by .

The finite element simulation is currently a powerful tool to optimize forming processes in order to produce defect-free products. Wrinkling and springback are main geometrical defects arising in .

Surface defects are small concave imperfections that can develop during forming on outer convex panels of automotive parts like doors. They occur during springback steps, after drawing in the..describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges Objectives

In this work, the federated learning methodology is applied to predict defects in sheet metal forming processes exposed to sources of scatter in the material properties and process.In this paper, we take a machine learning per-spective to choose the best model for defects prediction of sheet metal forming processes. An empirical study is presented with the objective to choose the best machine learning algorithm that will be able to perform accurately this task.

This paper focuses on developing a generic functional data analysis based approach to quantify geometric error/shape error which are generated by process or material parameters (such as material thickness, stamping speed and blank holding force) during sheet metal forming process.In this work, an approach to extract information from a sheet metal forming processes, exposed to sources of scatter in the material properties and process parameters, is proposed in order to enable the prediction of defects.

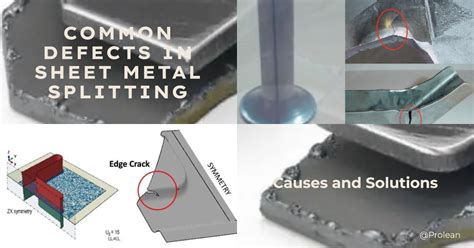

In deep drawing metal sheet is subjected to high punch pressure which causes deformation of material, during deformation stresses are generated in various zones, which leads to various defects. The predominant failure modes in sheet metal parts are wrinkling and fracture.Accurate prediction of forming defects is essential for the sheet metal forming process. In this paper, an approximation model technique based on Gaussian process regression(GPR) is proposed to predict the forming defects in sheet metal forming process.Some of these defects are caused by the forming tools (types 5, 9, 10, 14), by the friction regime (types 4, 13) or by the mechanical and metallurgical properties of the material as well as by geometrical parameters (types 1,2,3,6, 7, 8, 11, 12). Only the defects of type 3, 6,8 are related to stretching processes, the others are.

The finite element simulation is currently a powerful tool to optimize forming processes in order to produce defect-free products. Wrinkling and springback are main geometrical defects arising in sheet metal forming.

Surface defects are small concave imperfections that can develop during forming on outer convex panels of automotive parts like doors. They occur during springback steps, after drawing in the..describe different forming processes, when they might be used, and compare their production rates, costs and environmental impacts .calculate forming forces, predict part defects (tearing, wrinkling, dimensional inaccuracy), and propose solutions .explain current developments: opportunities and challenges Objectives

In this work, the federated learning methodology is applied to predict defects in sheet metal forming processes exposed to sources of scatter in the material properties and process.In this paper, we take a machine learning per-spective to choose the best model for defects prediction of sheet metal forming processes. An empirical study is presented with the objective to choose the best machine learning algorithm that will be able to perform accurately this task.

This paper focuses on developing a generic functional data analysis based approach to quantify geometric error/shape error which are generated by process or material parameters (such as material thickness, stamping speed and blank holding force) during sheet metal forming process.In this work, an approach to extract information from a sheet metal forming processes, exposed to sources of scatter in the material properties and process parameters, is proposed in order to enable the prediction of defects.In deep drawing metal sheet is subjected to high punch pressure which causes deformation of material, during deformation stresses are generated in various zones, which leads to various defects. The predominant failure modes in sheet metal parts are wrinkling and fracture.

Accurate prediction of forming defects is essential for the sheet metal forming process. In this paper, an approximation model technique based on Gaussian process regression(GPR) is proposed to predict the forming defects in sheet metal forming process.Some of these defects are caused by the forming tools (types 5, 9, 10, 14), by the friction regime (types 4, 13) or by the mechanical and metallurgical properties of the material as well as by geometrical parameters (types 1,2,3,6, 7, 8, 11, 12). Only the defects of type 3, 6,8 are related to stretching processes, the others are.

surface defects in sheet metal PDF

sheet metal forming tools

Check out our vertical house numbers metal selection for the very best in unique or custom, handmade pieces from our address signs shops.

defects in sheet metal forming process pdf|surface defects in sheet metal PDF