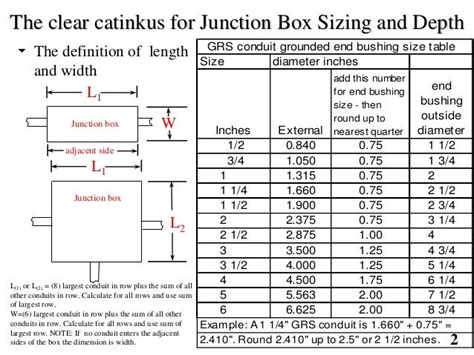

what is a pull box electrical You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For . Bending is one of the most common sheet metal fabrication techniques. With bending, metal is deformed with specialist machinery into an angular shape. The bending of sheet metal allows .

0 · standard pull box size chart

1 · nec distance between pull boxes

2 · maximum distance between junction boxes

3 · interior electrical pull box

4 · electrical pull box size chart

5 · electrical box size chart

6 · electrical box size calculator

7 · different types of pull boxes

What Are Solar Panel Junction Boxes? A solar panel junction box is an essential enclosure that houses the electrical connections of a solar panel. It serves as the central hub for the panel’s electrical circuit, allowing the interconnection of various components within the system.

A pull box describes an electrical box that gives access to pull electrical cables through non-metallic or metallic raceways and conduit. They give you a means to pull .Pull boxes are enclosures used to facilitate the pulling, splicing, and maintenance of electrical wiring within a conduit system. These boxes are strategically placed to provide access points along the conduit run, making it easier to manage .

You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For . A pull box is an electrical box placed at key locations in electrical conduit wiring systems in order to provide access in order to pull electrical wires through conduit during wiring installation. Illustration: a small pull box or . SHOP ELECTRICAL BOXES NOW. IMPORTANT: The National Electrical Code (NEC) and local building codes regulate the types of electrical boxes allowed in certain applications, as well as how they’re installed. Per their requirements, electrical boxes must be covered with matching electrical box covers.Odd. While you have a wall switch on the wall under these two boxes, these don't seen to serve any purpose other than junction or pull boxes I guess. Testing the wires in each with a circuit tester might tell you more, like if they are fed by .

2795 items found for "pull box for electrical " Sort By: Best Match. View: Fumaco Pull Box, Gauge 16 and Gauge 22 , Concentric Knock-out 0.7mm or 1.2mm thick metal pull box conduit ₱189. Voucher save 28%. 1.6K sold (188) Metro Manila~Caloocan.The meaning of PULL BOX is a metal box with a blank cover that is installed in an accessible place in a run of conduit to facilitate the pulling in of wires or cables.Pull boxes are used along with conduit to simplify wiring installation, hence their name.They are made of sheet metal, cast metal, or a non-metallic material, and provide a way to pull conductors long distances without placing excessive strain on the wire or insulation.Pull boxes allow long wiring runs to be installed in shorter intervals, and can be used for both straight and angled pulls.

Apply appropriate personal protective equipment (PPE) and follow safe electrical work practices. See NFPA 70E, NOM-029-STPS-2011, or CSA Z462. This equipment must only be installed and serviced by qualified electrical personnel. . DO NOT lift the cabinet by the pull box or by attaching lifting angles to the pull box. Failure to follow these . It makes it look like the EYS would be located above grade or half in/out of the pull box. That is not the case at all. It would be located completely inside the pull box. Now, to your question, the reason there's a concrete pull box at this location is because there are ~8-10 conduits passing through it. It's a normal electrical pull box. Electrical box covers enclose the front of the box and are required by code; it is unsafe, and usually illegal, to leave an electrical box uncovered. Solid or blank covers have no holes and are used with junction boxes or for enclosing unused boxes. Covers for 4-inch square boxes may have special cutouts to accommodate switches or receptacles . Does anyone know who make 2-hour fire rated wire way or pull box? Tks If you look at UL listing for Metallic Outlet Boxes (QCIT), it seems that any listed metal box can acheive a 2-hour rating when installed in accordance with that listing.

Hi, I was wondering how to size a pullbox for a cable tray. I have 2 parallel runs of 18" cable trays running from a tesla megapack battery to a pull box. What size pull box do I need? Is there an NEC code section I can look at?Electrical 2'6"x4'x2'6" Pull Box - Concrete pull box / handhole for heavy duty traffic conditions with conduit recesses and galvanized steel cover.

One such component is the electrical pull box. If you are not familiar with what a pull box is or how it is used, this blog post will provide you with all the information you need. What is an Electrical Pull Box? An electrical pull box, also known as a junction box, is a container that is used to house electrical connections andThe following article is designed to help you understand what factors to consider in choosing the proper traffic rating for pull boxes and covers. Should you have any questions, please call our experts at 800-767-1576, contact us or view traffic rated pull box products for information on each specific enclosure. I have a situation on a job where there is an existing pullbox that needs to be replaced. Sounds simple but the box is almost 7 feet wide and 4 feet tall. It also has 28 4" conduits in it. That asside it only has 20 inches of clearance in front. There is a chiller in the way. 110.26 says minimum. Vertical pulls present a completely different set of rules. Conductors are required to be supported. If you have a 500' straight vertical pipe run and pull in 500 Kcmil conductors you'll need a pull box every 50' to support the conductors.

The engineer on the project has been no help. We have 12-4” sch 40 pvc with 4-750kcmil with one 500kcmil. This is feeding a 4000 amp switch. Any info would be great. I do understand the code on pull box sizing with the 8x rule. However, I feel that there should be a way larger underground pull box installed for any maintenance and or repair.For an angle pull, the minimum size pull box or junction box is determined by multiplying the largest conduit trade size dimension by____ and adding the trade size of each of the other conduits to get the minimum pull box or junction box dimensionsPull Box – are used along with conduit to simplify wiring installation, hence their name. They are made of sheet metal, cast metal, or a non-metallic material, and provide a way to pull conductors long distances without placing excessive strain on the wire or insulation.

gg metal fabrication

Round Pull Box, Diameter: 9", Depth: 12", Concrete Item #: 0015341 CAT #: 1000370 UPC: 800246159537 $ 50.92 EA. Company wide: 238 in stock Add to Cart Oldcastle Precast Heavy Duty Box with Lid, 11" x 18" x 12" .

standard pull box size chart

A U pull is where two raceways enclosing the same conductors are located on the same wall of a box. Calculate a box containing both angle and U pulls by the same method as angle pulls. For example, a box will contain angle and U pulls. The bottom of the box contains two 2-inch conduits that will enclose the same conductors.

It's pretty funny because my foreman, who is very code savvy also tells us to put a pull box every 100 feet! He also cites the NEC a the reasoning but never quotes a specific section or article but then again maybe it's a commercial thing because we were also taught to have a pulling point every 5 floors which I have to say I agree with 100%.The National Electric Code (NEC) specifies a minimum size for pull, junction box and conduit bodies. The code specifies this based on whether it is a straight pull or the conductor turns in an angle or u pull. The code treats a splice internal to the box the same as an angle or u-pull.We supply electrical pull boxes and handholes for applications and installations in electrical utility, telecommunications, construction, transportation, and water utility industries. We carry an array of underground pull box sizes and specifications, including Quazite boxes made from pre-cast polymer concrete. Our pull boxes perform to make .

get schneider junction box

A junction box is always a pull box, but a pull box isn’t always a junction box. I mainly use pull box for feeder raceways as there shouldn’t be junctions, but call branch circuit raceways junction boxes as it’s common to split off from them. In reality it doesn’t matter, they are both boxes and installing an 8x8x4 pull box is no . Hello all. Anyone know if the workspace requirements of 110.26 apply to pull boxes where the pull box has not taps or live energized parts. Just cabling passing through and used as a pull point. If there are no workspace requirements in the NEC, does OSHA have workspace requirements? Thanks. cStudy with Quizlet and memorize flashcards containing terms like Determine the maximum number of conductors permitted for each of the following applications in accordance with Article 314. 6 AWG TW conductors in a 4 in. × 11/2 in. square box 12 AWG THHN conductors in a 411/16 in. × 11/2 in. square box 14 AWG TW conductors in a 3 in. × 2 in. × 11/2 in. device box 14 .

nec distance between pull boxes

Metal fabrication is a manufacturing process used to shape metal into parts or end products. It usually consist of three phases: 1) design, where shop drawings are created to the intended measurements; 2) fabrication, which involves .

what is a pull box electrical|electrical pull box size chart