production cnc machining Mike Medeiros, production manager at North Easton Machine Co., has been advocating CNC Swiss lathes for years, attempting to persuade his local high school’s administration to add the technology to the school’s machining program.

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques.

0 · what is cnc in manufacturing

1 · how does cnc machine work

2 · cnc manufacturing technology

3 · cnc machining operations

4 · cnc machining manufacturing process

5 · cnc machining manufacturing

6 · cnc machining capabilities

7 · cnc machine fabrication

Oil canning is an inherent characteristic of light-gauge, cold-formed metal products with broad, flat areas. It is a moderate deformation that is cosmetic and not grounds for panel rejection. It's an aesthetic concern that is observed as waves or wrinkles, in the flat areas of metal roofing and metal siding panels.

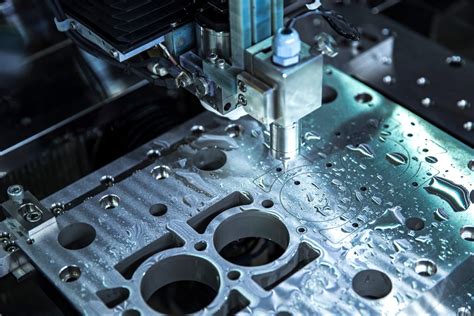

Production CNC machining involves the specialized use of CNC (Computer Numerical Control) technologies geared specifically for high-volume manufacturing. This . The online extension of Production Machining magazine and the most comprehensive site available for high volume precision machining professionals.Production CNC Machining & Turning with rigorous environmental controls, precision tooling and fixturing, and advanced metrology processes, you won’t get closer to perfection than with Prismier.Production CNC Machining. Trulife Engineered Solutions machining department has 35 CNC machines running on multiple concurrent shifts. Our significant capacity allows us to take on a variety of large projects. We work aggressively .

CNC machines are modern subtractive manufacturing equipment, which automatically control the tool path and movement for material removal. You can find different types of CNC machines in industrial factories and the CNC Machine Shop, each with specific manufacturing purposes.However, all of them are used to craft the blank work material into the . Mike Medeiros, production manager at North Easton Machine Co., has been advocating CNC Swiss lathes for years, attempting to persuade his local high school’s administration to add the technology to the school’s machining program.Rapid Prototyping. Rapid Axis’s CNC machines are great for prototype manufacturing.Since the machine runs quickly and creates highly accurate parts, you can have a functional prototype created in days.. CNC machines tend to make pieces in production-grade metals or plastics, so the prototype you get will be fully operational.With over 30 different CNC platforms we support small batches to large production runs. Horizontal Boring Mills With 6 large horizontal boring mills we can machine parts up to 12 cu ft /60000Lbs. 3 of our HBMs have the unique U Axis ability- excellent forconical bores and other internal features.

CNC machining is revolutionizing the manufacturing industry. Learn about the different types of CNC machines, the pros and cons of each, and a comprehensive guide to the CNC machining process. . CNC machine tools for machining can accurately calculate the working hours of a single product and reasonably arrange production. CNC machine tools .Our 3-axis CNC machining capabilities feature a machining envelope of up to 35" x 18" x 18, with tolerances ranging from .0005 to .005. To meet high demand, our machining centers are tailored for both high-speed machining and large-volume workflows, typically handling quantities ranging from 1,000 units to well over 100,000 EAU or more.Founded in 1975, Production Saw and Machine provides high-quality CNC machining, turning, and sawing for diverse markets. Since 1975, we have provided precision CNC machining and sawing services tailored to various industries. Our offerings include high, medium, and low-volume machining, metal cutting and sawing, and expertly crafted metal . Computer numerical control (CNC) is used by modern machine tools to program and control movement of key machine components during machining operations. . Production Machining’s September 2024 technology showcase includes some of the latest technology from Expand Machinery, Paperless Parts, Monaghan Tooling Group, Walter USA and more. .

1 - Haas EC-500 Horizontal Machining Center; 2 - Haas VF-5 Vertical Machining Centers; 2 - Haas VF-6-50 Taper Vertical Machining Centers; 2 - Haas VF-3 Vertical Machining Centers; 2 - Haas CNC Vertical TM-2 Mills; 1 - Haas VF-4 VMC w/40 Station Tool Magazine, 50" x 20" x 25" 4th Axis; 1 - 2005 Haas VF5/50 CNC VMC 10,000 rpm, 4th Axis indexer CNC production machining is a more sophisticated, elaborate, and high-volume manufacturing process than standard CNC machining. CNC machining parts for production emphasizes precision, elimination of internal scrap, and enhanced product quality and throughput, to boost both the bottom line and customer satisfaction. What Are the Different Types .Production Capabilities for CNC Machining. Our service is all about solutions and flexibility. We take time to understand your project and leverage our global network to find the right manufacturer for the job. We can help get products ready for market with: Cosmetic finishes; Multiple surface finish options; Tight tolerances; Custom materials

How Does Production CNC Machining Work? The process of production CNC machining is a symphony of six precise, automated steps, from raw material to finished product. Material Selection and Preparation: Choosing the right material—whether metal, composites, or plastics—is critical. The properties of the stock material such as hardness and .

what is cnc in manufacturing

The wide range of available materials compatible with CNC machining makes the production of a final part even faster than traditional manufacturing. CNC machining remains the preferred method used when traditional manufacturing .CNC MACHINING , MILLING MACHINIG , CNC TURNING PRODUCTION AND PROTOTYPE . Our Services. . Catering to specialized and niche requirements, we offer small-scale production runs. Whether you're an individual needing a few parts or a business requiring a limited run, we ensure the highest quality in every piece we produce. .CNC Machining: Beyond Algorithmic Precision: While CNC machining provides the backbone of high-volume production, its effectiveness hinges on far more than simply pre-programmed instructions. Sophisticated CAM software, coupled .

There is plenty more to learn about CNC machining in our Knowledge Base - a collection of technical articles on all manufacturing technologies, written by manufacturing experts and curated by Protolabs Network. Here is a selection of our most popular articles on CNC machining: Reducing the cost of CNC machined parts →; 3D Printing VS. CNC . The CNC precision machining techniques, milling, turning, drilling, and EDM, are flexible with the production volume, whether you need a few prototypes or large-scale runs. Consequently, the just-in-time manufacturing strategy can reduce custom parts’ setup, tooling, and machining time. CNC production machining is a cutting-edge manufacturing process that utilizes advanced CNC machines to achieve high-volume production with exceptional accuracy and precision. This technology allows manufacturers to produce complex metal and plastic parts and components with tight tolerances, excellent dimensional accuracy, and superior quality CNC production machining is in two ways. There is a Low volume CNC machining and high-volume CNC production machining. From the names, you must have guessed what the two means. However, there is more to it than what the names let on. In this section, we will treat both types of CNC production machining and their benefits. Low volume CNC machining

CNC precision machine shop in Santa Clara providing CNC machining services, milling, turning, Wire EDM; prototype + high-volume production in the bay area. 408-564-4809 Santa Clara, CA "Discover how CNC machining is revolutionizing metal part production. From 3D CAD designs to flawless metal components, this video covers the essential techn.Prototype CNC Machining can produce your prototype parts. Whether your prototype will lead to a production run, or if it is a stand-alone piece or fixture, we are here to help. Our machines and extensive experience allow us to minimize the number machining operations and reduce run times, which keeps costs down. CNC Machining’s technical [.]We are a walk-in player with extensive production CNC machining experience. Success with any repeat CNC machining starts with state-of-the-art tools, and Napoleon Machine has a long track record of investing in new machining tech. For example, we use custom-built modular fixtures, .

At PCR MACHINING, INC., our exemplary journey began in 1923 on the west side of Chicago. What started as a dedicated production of connecting rods has now flourished into a full-service, single-source CNC manufacturing powerhouse. With decades of expertise under our belt, we specialize in crafting custom components for a wide range of industries. PMTS Founded in 2001, PMTS reconvenes in April 2025 to celebrate its 13th biennial event for precision machining pros. Mark your calendar now and plan to join the precision machined parts community when we once again gather in person to share challenges and insights, see new technology solutions and learn about process innovations – everything you .

how does cnc machine work

cnc manufacturing technology

cnc machining operations

This article dives into the properties, types, and applications of galvanized sheet metal, revealing its effectiveness in rust prevention and durability. From hot-dip to electro-galvanized sheets, discover the different .

production cnc machining|how does cnc machine work