breaker box as junction box You don't need to do that -- you can get a flush-mount box by itself that fits your needs. What you're looking for isn't a "breaker panel", really. It's .

We specialize in custom metal fabrication work, wrought iron handrails, and welding services. Our staff offers quality and reliable service that you can count on. We design, fabricate, paint, and install all of our own projects.

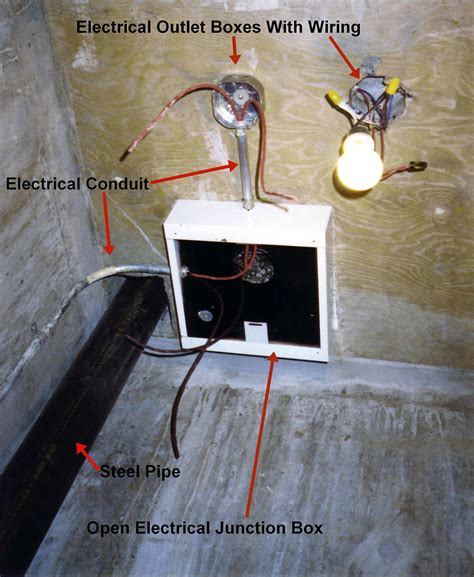

0 · what is a junction box

1 · metal junction box

2 · junction box for wiring

3 · how to use a junction box

4 · fuse box for junction box

5 · electrical junction box problems

6 · electrical junction box extension

7 · electrical junction box

Check the next night...more pin holes! This has gotten real old so I figured out how to find pin holes in day light. Take a empty toilet paper tube,and put it over the weld seam tight against the steel. Put your eye over the tube,and slowly move a long the seam while holding the flash light inside the door.When you hit a pin hole it will .

I'd like to convert my existing 100-A panelboard to a junction box (a new 200-A panelboard is being installed about 15' from the existing panel). My naive question: are there any particular rules to follow for making the specific junctions within the new panel?You can get extension boxes (that size box with an open back designed to stack on .

You don't need to do that -- you can get a flush-mount box by itself that fits your . You can get extension boxes (that size box with an open back designed to stack on an existing box). The deeper 4 x 4 x 2.125" box is 30 . A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings. You don't need to do that -- you can get a flush-mount box by itself that fits your needs. What you're looking for isn't a "breaker panel", really. It's .

I have allowed electricians to use existing panels as junction boxes; as long as the hinged door is screwed shut. This way the existing panel cover acts as your cover plate. It .

Explore the world of electrical junction boxes – their crucial role, types, installation tips, and safety measures. Uncover the power of junction boxes in securing your electrical system. A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers .

Then you can gut all the breakers out and use the remaining box as a junction box. It will need a proper cover. Get a bunch a blank slugs to plug the holes where the breakers .

You may know the service panel as the breaker box, while in the trade it's officially called a load center. The main service panel is like the switchboard for all the electricity in the home.

I'd like to convert my existing 100-A panelboard to a junction box (a new 200-A panelboard is being installed about 15' from the existing panel). My naive question: are there any particular rules to follow for making the specific junctions within the new panel? You can get extension boxes (that size box with an open back designed to stack on an existing box). The deeper 4 x 4 x 2.125" box is 30 cubic inches. The larger 4-11/16" (120mm) square box is 42 cubic inches*

A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings. You don't need to do that -- you can get a flush-mount box by itself that fits your needs. What you're looking for isn't a "breaker panel", really. It's just the cabinet that the breaker panel came in, so just get a suitable box instead.

When you run out of space in your electrical service panel (also called a breaker box), you have two choices: have a professional upgrade the service panel or install a subpanel yourself. I have allowed electricians to use existing panels as junction boxes; as long as the hinged door is screwed shut. This way the existing panel cover acts as your cover plate. It should also be marked accordingly. :thumbsup:

Explore the world of electrical junction boxes – their crucial role, types, installation tips, and safety measures. Uncover the power of junction boxes in securing your electrical system. A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or . Then you can gut all the breakers out and use the remaining box as a junction box. It will need a proper cover. Get a bunch a blank slugs to plug the holes where the breakers were. Or cut a piece of sheet metal to replace the panel front with the breaker holes.

You may know the service panel as the breaker box, while in the trade it's officially called a load center. The main service panel is like the switchboard for all the electricity in the home.

I'd like to convert my existing 100-A panelboard to a junction box (a new 200-A panelboard is being installed about 15' from the existing panel). My naive question: are there any particular rules to follow for making the specific junctions within the new panel? You can get extension boxes (that size box with an open back designed to stack on an existing box). The deeper 4 x 4 x 2.125" box is 30 cubic inches. The larger 4-11/16" (120mm) square box is 42 cubic inches*

A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings. You don't need to do that -- you can get a flush-mount box by itself that fits your needs. What you're looking for isn't a "breaker panel", really. It's just the cabinet that the breaker panel came in, so just get a suitable box instead.

When you run out of space in your electrical service panel (also called a breaker box), you have two choices: have a professional upgrade the service panel or install a subpanel yourself. I have allowed electricians to use existing panels as junction boxes; as long as the hinged door is screwed shut. This way the existing panel cover acts as your cover plate. It should also be marked accordingly. :thumbsup: Explore the world of electrical junction boxes – their crucial role, types, installation tips, and safety measures. Uncover the power of junction boxes in securing your electrical system.

A junction box is not a special type of box but any standard electrical box used to enclose wire splices. The most commonly used box for junctions is a 4-inch square box (either metal or strong plastic), which offers ample space for making wire connections with multiple wires or . Then you can gut all the breakers out and use the remaining box as a junction box. It will need a proper cover. Get a bunch a blank slugs to plug the holes where the breakers were. Or cut a piece of sheet metal to replace the panel front with the breaker holes.

what is a junction box

metal junction box

It is imperative you consider the shielding gas, welding process, and electrode before welding 20-gauge sheet metals. In the US sheet metal is designated through the gauge, the larger the number the thinner the metal. Typically, the .

breaker box as junction box|electrical junction box problems