cnc turning part cost example CNC machining costs are influenced by multiple variables. In this section, we will explore factors such as material selection, design complexity, part size, and tolerances. Each factor will be . Discover stunning white brick houses with metal roofs that exude elegance and charm. Find inspiration for your dream home and create a timeless look with these top ideas.

0 · round cnc milling cost

1 · round cnc machining cost

2 · machining costs for cnc machines

3 · how to calculate machining costs

4 · how to calculate cnc cost

5 · cnc machining cost estimator

$17.50

round cnc milling cost

In this example, the total CNC machining cost for producing a part from aluminum alloy, considering material, labor, machine, tooling, and overhead costs, is 50. It’s crucial to adapt this example based on the specific details of your project, . The cost of CNC machined parts can vary significantly depending on several key factors. If you want to reduce your cost of CNC machined parts then this article will help you in .

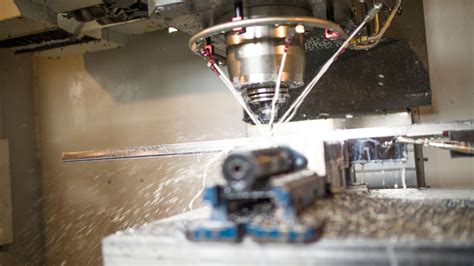

cnc milling machine 5 axis

In this comprehensive guide, we will delve into the various aspects of CNC turning part pricing, discuss the factors that affect costs, provide cost analysis examples, and offer valuable tips to . Begin by evaluating the material requirements for the specific component or part. Consider the material price per unit and the total quantity required. Estimate the machine cost by factoring in depreciation, .CNC machining costs are influenced by multiple variables. In this section, we will explore factors such as material selection, design complexity, part size, and tolerances. Each factor will be .

In this comprehensive guide, we will delve into the factors that influence the cost of CNC turning parts, explore the latest trends in the industry, and provide a detailed analysis of pricing to help .CNC Turning is a highly efficient machining process used to create cylindrical parts with exceptional precision. During this process, a cutting tool removes material from a rotating workpiece, producing parts with tight tolerances and .

How much does CNC machining really cost? A simple CNC part can cost from as low as 0 per piece, while larger metal parts might escalate into several thousand dollars or higher.To get a rough estimate, a few factors determine how much it will cost to CNC machine a custom part. Read on to learn more. One of the most impactful factors to consider for the CNC machining price is part complexity.In this example, the total CNC machining cost for producing a part from aluminum alloy, considering material, labor, machine, tooling, and overhead costs, is 50. It’s crucial to adapt this example based on the specific details of your project, including material type, machining complexity, and other unique factors.

The cost of CNC machined parts can vary significantly depending on several key factors. If you want to reduce your cost of CNC machined parts then this article will help you in planning and budgeting for CNC machining projects effectively.In this comprehensive guide, we will delve into the various aspects of CNC turning part pricing, discuss the factors that affect costs, provide cost analysis examples, and offer valuable tips to help you optimize your budget. Begin by evaluating the material requirements for the specific component or part. Consider the material price per unit and the total quantity required. Estimate the machine cost by factoring in depreciation, maintenance, and the time it takes to complete the machining process. The comprehensive guide provides you with the basics, design considerations, materials, surface finish, cost, and more about CNC machining to help you create quality machined parts with aesthetic appearance.

CNC machining costs are influenced by multiple variables. In this section, we will explore factors such as material selection, design complexity, part size, and tolerances. Each factor will be explained in detail, including its impact on machining time, tooling requirements, and overall cost.In this comprehensive guide, we will delve into the factors that influence the cost of CNC turning parts, explore the latest trends in the industry, and provide a detailed analysis of pricing to help you make informed decisions for your manufacturing needs. Word count: 105. Section 1: Understanding CNC Turning Parts Price:\ Word count: 150.CNC Turning is a highly efficient machining process used to create cylindrical parts with exceptional precision. During this process, a cutting tool removes material from a rotating workpiece, producing parts with tight tolerances and superior surface finishes.How much does CNC machining really cost? A simple CNC part can cost from as low as 0 per piece, while larger metal parts might escalate into several thousand dollars or higher.

To get a rough estimate, a few factors determine how much it will cost to CNC machine a custom part. Read on to learn more. One of the most impactful factors to consider for the CNC machining price is part complexity.In this example, the total CNC machining cost for producing a part from aluminum alloy, considering material, labor, machine, tooling, and overhead costs, is 50. It’s crucial to adapt this example based on the specific details of your project, including material type, machining complexity, and other unique factors. The cost of CNC machined parts can vary significantly depending on several key factors. If you want to reduce your cost of CNC machined parts then this article will help you in planning and budgeting for CNC machining projects effectively.

In this comprehensive guide, we will delve into the various aspects of CNC turning part pricing, discuss the factors that affect costs, provide cost analysis examples, and offer valuable tips to help you optimize your budget. Begin by evaluating the material requirements for the specific component or part. Consider the material price per unit and the total quantity required. Estimate the machine cost by factoring in depreciation, maintenance, and the time it takes to complete the machining process. The comprehensive guide provides you with the basics, design considerations, materials, surface finish, cost, and more about CNC machining to help you create quality machined parts with aesthetic appearance.CNC machining costs are influenced by multiple variables. In this section, we will explore factors such as material selection, design complexity, part size, and tolerances. Each factor will be explained in detail, including its impact on machining time, tooling requirements, and overall cost.

In this comprehensive guide, we will delve into the factors that influence the cost of CNC turning parts, explore the latest trends in the industry, and provide a detailed analysis of pricing to help you make informed decisions for your manufacturing needs. Word count: 105. Section 1: Understanding CNC Turning Parts Price:\ Word count: 150.CNC Turning is a highly efficient machining process used to create cylindrical parts with exceptional precision. During this process, a cutting tool removes material from a rotating workpiece, producing parts with tight tolerances and superior surface finishes.How much does CNC machining really cost? A simple CNC part can cost from as low as 0 per piece, while larger metal parts might escalate into several thousand dollars or higher.

round cnc machining cost

machining costs for cnc machines

cnc milled parts factory factory

how to calculate machining costs

Sheet metal bending tools are essential for shaping and manipulating metal sheets. Common sheet metal bending tools include the brake press, box and pan brake, and slip roll. Each tool has its own unique features and capabilities, allowing for different bending techniques.

cnc turning part cost example|round cnc machining cost